Sorry. First you must buy rs232(female) to usb because jpt use male connectors in their sources. Next connect rs232 cable to jpt source and to pc. Check com port of cable in devices. Com must be 1-4. Open software and connect your laser. EASY!

Check the stuff that came with the laser. Mine came with one.

This is from Mauser.pt but maybe Mauser USA?

https://mauser.pt/catalog/product_info.php?products_id=047-0251

https://mauser.pt/catalog/product_info.php?products_id=047-0041

I guess a better way of asking this, is a standard usb to rs232 female, not special wiring for the jpt?

@parsec, thanks… I’m in the US, but I now know what to look for

I will hunt around… thanks

![]()

yes, not special cable.

Hello @JohnJohn , have you already received an answer from the galvo team regarding my original problem?

The problem with the q-pulse value has not yet been solved. Does anyone else have an idea?

Have you tried the gator with slightly lower power? Another way to test, try a couple lower power settings until the gator starts to fade, then change Q pulse from 8 to 200 see if there is a difference. Try Q-Pulse=1 and see if there is a difference. Where I’m going with this is coloring stainless steel takes a lot of playing around, not exact science. I think possibly it is not a material test burn vs regular burn problem.

hello Albroswift,

I haven’t tried it yet, but I’ll give it a try.

The good thing about the meterial test is, that I can test different parameters at once with the material, so that I can use these parameters for my actual work.

But if I can’t use the parameters of the material test, why is the material test there?

Material test gets you close. The squares in the material test are small and uniform, Gator is not. Takes some fine tuning. I’d bet you were within a few % of your desired effect. When I ran your numbers from the test (Adjusted for power) it was very little spread from too light to too dark but a good green looked like to me. Just the nature of SS. Takes a LOT of testing.

Not just stainless…

![]()

Hi,

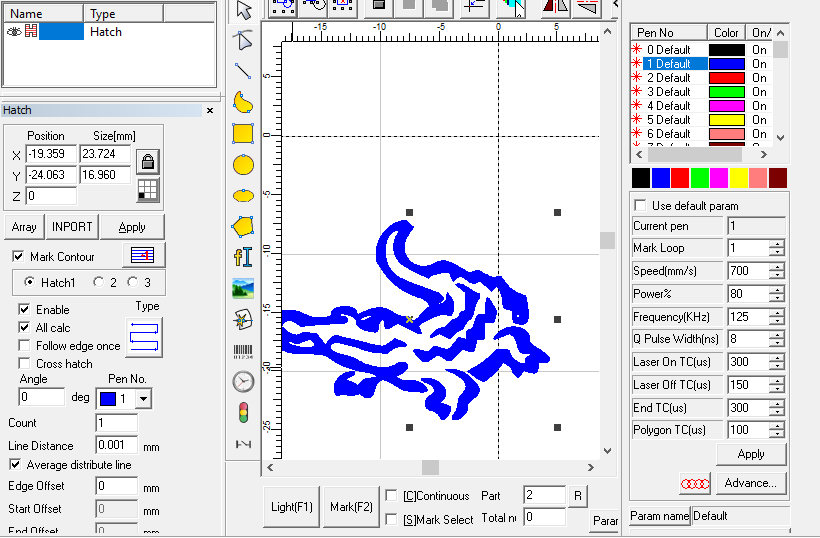

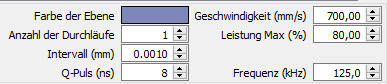

I loaded the same image into EZCAD2 and engraved it with the same parameters. EZCAD2 engraves the image in the color it should be.

@JohnJohn

You haven’t reported back.

Have you received an answer from your galvo Team about this issue?

Hello, @gummi2000 just following along.

So if I am understanding correctly, the photo on the right is EZ2, and the left is LB 1.6.03 +/-, both using identical settings? This is really good for comparison, now can you post screenshots of all the settings?

One thing I see, maybe nothing, just trying to remove all variables. Looks like different sides of the dogtag or different dogtags.

The only thing I’m seeing is the cutoff frequency on Page 8 of the User Manual is 375 kHz for 8nS. At 125kHz the laser will operate in a reduced power mode. It’s supposed to be linear and I’m not certain that it’s the important factor.

If I’m reading the material test correctly, you have to put more power down,

Please test your 'gator (45 degree engraving) at 500mm/s. I want to see if the results are considerably closer or still far off.

Hello @Albroswift,

yes thats true, right is EZ2 and the left is LB 1.6.03

I made screenshots from the EZ2 and LB settings.

The dogtags were engraved on different sides, but the tags are from the same batch.

Hello @JohnJohn,

Thanks for the tip with the table. I will carry out further tests when the opportunity arises, taking the manufacturer’s specifications.

By reducing the speed to 500mm/s the engraving would become darker instead of green.

@Sartori90

What problems did you find?

Have you already carried out tests with different parameters?

Only thing I don’t see is LB cross hatch “off” setting, wobble “off”, assume that’s what you have.

Did the 2 engravings take the same amount of time?

There is a guy on the LMA same thing, green QPulse =6 works in material test but same settings in parameters solid black. All screenshotslook identical. I can’t duplicate, unless I bump up the Q to larger number, then the green goes black.

So you are not alone.

no cross hatch and no wobble.

I haven’t checked whether the two engravings were finished at the same time.

I would guess the time is similar.

But what you can clearly see and hear is that the engraving with LB is done with “more energy” and therefore significantly deeper and louder engraving.

It’s nice that I’m not alone, but unfortunately that doesn’t help me. I want to understand the cause so I can do something about it (or not if it comes from LB)

Do you have the same laser type only with 60W?