Hello

My TwooTrees TS2 10 W has, 3 end switches that work very well.

And is it possible to add two more on x and y?

because in another subject I have a problem with the size of the work equipment.

If we can add more, should we set up a line in gcode? (if so, which one and with what value)

Will these end stops have to be wired in series or in parallel?

or screwed on the motherboard (I doubt that there are still posrts available!

*Thank you for your help and good projects!

You don’t need more end stops, just find the correct work size as described in the other thread.

It is possible, but not useful.

Do this instead:

- Configure GRBL to home correctly during startup

- Set the travel limits in

$130and$131to match the actual machine limits - Enable

Soft Limitswith$20= 1

Then the controller will not execute commands with coordinates moving the laser head beyond the platform limits.

The Hard Limits set by additional switches are useful in CNC machines driving cutting tools that can stall the motors during overloads. A correctly configured laser machine will not lose steps during operation, so the controller always knows where the head is and can prevent out-of-bounds motions before they happen.

Edit to add: As described in your parallel thread, the machine is not correctly configured. You must measure and set the actual machine limits before proceeding.

Huge thanks to you!

I slightly disagree here ![]() , there are use cases where it is useful. Though Ed is right basically. I fully agree that soft limits should make those obsolete, but most people (including myself) tend to move the laser head manually either to position it correctly or to move it out of the way (when dealing with the workpiece). In such a case, the positioning of the laser is lost, and soft limits do not help anymore.

, there are use cases where it is useful. Though Ed is right basically. I fully agree that soft limits should make those obsolete, but most people (including myself) tend to move the laser head manually either to position it correctly or to move it out of the way (when dealing with the workpiece). In such a case, the positioning of the laser is lost, and soft limits do not help anymore.

So, adding limit switches to the other ends is a good idea, depending on how you handle the laser. You can just wire them in parallel to the other switch on the same axis. The firmware can’t recognize which switch was pressed, but that’s not required at all since the operation is stopped, and you need to reset it anyhow. Many newer lasers (like Sculpfun A9) are already equipped with switches on each side of the axis.

Having started on CNC machines, I learned to not reach in there to shove things around, because the machine will bite back.

Sometimes I forget, but hearing the doctor say “See that white fiber? That’s the extensor ligament” smartened me right the [mumble] up again. ![]()

Smashing the laser head into the rail is less dramatic, but, still … ![]()

They must have had a lot of this happening. An extra switch, wire and time to assemble are not free.

The Ruida works a bit differently. It requires 6 switches, at minimum for 2 axes.

Four of these switches are outside the work area, once it homes (2 switches), those switches are ignored and it then monitors the limit switches (4 switches).

The drawback for this, to be useful is a loss of some of your working area. If it costs you $25k when you ran it out of bounds, it might be a more attractive option.

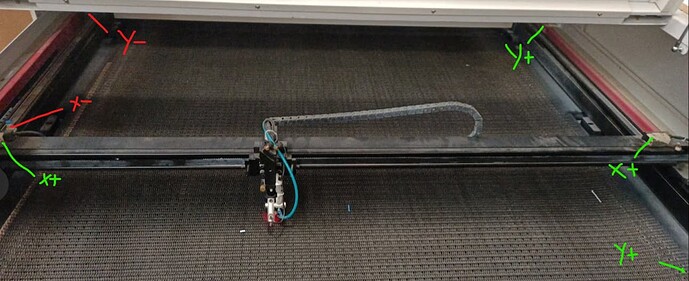

Red are home switches, green are limit switches.

Just an fyi…

![]()

Yes, I can imagine. And I think that’s a good idea for CNC and also for CO2 lasers. But I guess it’s quite common practice with diode lasers. Although it should be turned off while doing that, there’s not much risk in doing that, except that fast movements will damage the electronics through back powering them.

Yes, and I think that’s because it’s absolute common practice to move the head around manually with diode lasers. Personally, I also find it way more accurate and much faster to manually move the head to the edge of the workpiece and then start the job. Using the jog buttons takes ages. Maybe a game pad controller device would change this in the long run.