I recently bought a Chinese 180 watt co2 laser. Installed a new laser tube. It engraves perfectly functions great however I cannot get it to cut through thick materials in one pass. Laser mirrors are dialed in any suggestions? It seems like I’m running a 40 watt laser

Title should say Mdf. Stupid auto spell. Or stupid woodworker. Lol.

You might want to include your power settings and speed.

Do you have air assist on? You probably need a lot of air to blow our the char.

Thanks for the input. I currently am running at 5” per minute power set at 65% air is at 35 psi. I just upped it from 20psi.

What kind of current is happening at 65% power?

Might be worth trying a different MDF board. I think some of the MDF boards use a particular glue that isn’t compatible with laser cutting.

As an aside, I use some 1x3" thick clear acrylic blocks as test blocks to help gauge the laser’s performance. I chased my tail for what seems like forever now with plywood issues until I accepted the fact that even at 100W if the laser hits a glue blob, it isn’t going to cut through it in any meaningful way – even when cutting 1/4" plywood. I finally accepted those need to manually cut/post process those areas with a chisel and moved on.

It is an excellent way to adjust and judge one’s laser focus. I have always used it and can as you write, only highly recommended.

Regarding glue bubbles, I often observe that even if I come through, the glue inside is almost exploded, leaving an unusable piece of wood with a grenade hole left ![]()

That same problem is really evident with plywood, especially the cheap stuff with large gaps inside. These seem to fill with excess glue, which as stated, isn’t what my laser likes.

I wish I could afford all of the acrylic I see everyone using so much of, especially the thick stuff. I purchased a ‘do-hicky’ from Sadler and he shipped a couple pieces of acrylic with it to test it. I don’t think anything is as confirming as ‘seeing it’…

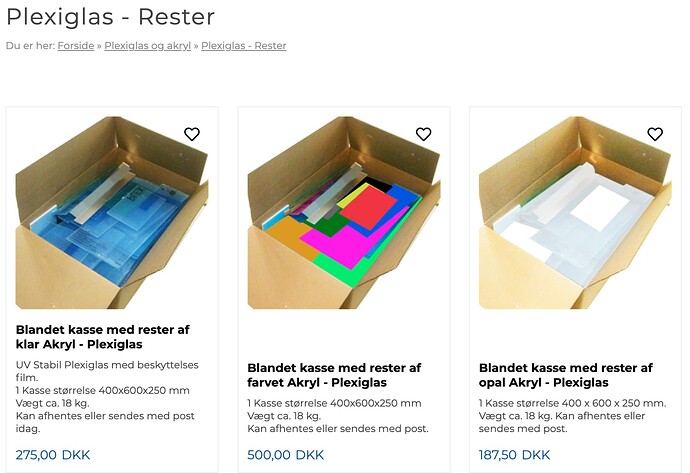

I am very lucky with the acrylic supply, from a large local company that trades in sheets of different materials and glass, I can buy a leftover package with approx. 16 kg cut-off. Most of the material is 2,3,4,5,6 mm, but also up to 20 mm. The size is up to 500 mm and the price is ok.

Here it’s left n*t and first newborn…

Most of what I cut I use the .0197" (about 2mm) off the shelf from Home Depot. It still costs about $10 for an 11 1/2 x 14" sheet. I mainly make use of it for templets/drill guides. Make most of the boxes I use from ply, wish I could make it out of acrylic.

I modified my tube mount, so it sticks out the right side. 3D printed a cover for it. I think next time I print it, I’ll leave the top off and cut a flat top plate with acrylic. Probably cut my print time in half or more.

Most interesting things I’ve found are using my 3d printer to make part for my little CNC machine or laser cut a part for some other machine… It appears there is no end in sight

Another jealous reader…

Take care

If the shipping cost was not so extremely high, I would like to arrange a deal with my supplier, but when he hears that it is going to the United States, the man falls from the chair

(For 1 US dollar you get approx. 6.3 DKK)

Thanks, that was my first thought when I saw the photos without reading it. Good way to make me green

That, of course, was not the intention. Could you not find a similar company in your state and ask nicely if they do not have any similar residues? Here we have e.g. a lot of craftsmen who have built corona screens and accessories, they have a lot of leftovers that can not really be used for anything else. Ask, it could be you are lucky.

Recently I have seen a supermarket which has “refurnished” the store, there were many 10mm acrylic shelves for cosmetic items that have just been thrown out!

Yes, that was a thought after peculating on your post. There is a company in Phoenix that sells and cuts acrylic. I’m going to see if I can make some kind of deal to buy scraps or something from them. Slap myself up the side of my head for not doing that while I lived down there. They must toss some of that stuff…

That’s a great idea about the scrap shelves. The acrylic business really boomed here. Every business has a bunch of acrylic shields or whatever thanks to covid…

Thanks

That works out to 127 mm/minute, or about 2.12mm/second, which is really slow.

What is your Min Power setting? If it’s not also 65%, then you’re not asking for 65% power. When the laser is moving very slowly, only Min Power is used. When you pass the ‘Start Speed’ setting in the controller, that’s when it begins to ramp from Min Power up to Max Power. If you never go faster than ‘Start Speed’, you never get Max Power.

Start Speed defaults to 10 mm/sec on most lasers, and you’re well under that.

Glad someone with their head on straight answered this… Thanks Oz, guess we were all somewhere else.

Peculating? What part of his post did you steal?

It was supposed to be percolating…

Nobody seems to have mentioned focus, so here’s my 2p worth of example.

Your focal depth (FD) needs to be set to 50% of your material thickness

I have a 2.5 inch focal point, aka 63.5mm.

For 6mm wood my FD would be 60.5mm, 3mm-62mm, surface-63.5mm

My measurements are taken from the base of the lens collar to material surface.

If you’re already set to this, ignore the above