HI,

I hope some of you guys still use these lasers and might be able to help me figure things out better.

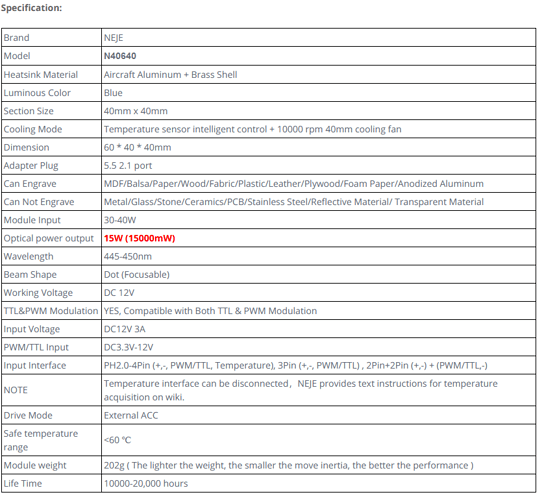

I just bought a “NEJE Max 4 A40640 Laser Engraver, 12W Zoom Output Laser Cutter, 29.6"x18.11” 4 Axis Industrial Laser Engraving Machine for Wood, Metal, Paper, Fabric, Acrylic, etc" about 2 weeks ago and its taken every bit of extra time to go from knowing nothing with a computer and design background to; I think I got this. I still don’t fully understand how you focus this laser and with the cool but complicating z-axis, I feel like its been a very complicated thing to figure out. You have a variable height to the bed, variable focus, and a moving z access. I’m getting there but its week 3 and instructions are not great.

So, because I am new, it took me a week and a half roughly to figure out I should lift the material off the pine bed I have the laser on. NOW I bought little 41 ish mm wood blocks from Michaels and have these blocks sitting on a baking sheet under the material I intend to cut. This is version 3 of the bed.

On top of these blocks I have placed some 4mm hardwood (not ply). Its the bottom of some old drawers and this is all I know about it. Its also kind of warped but probably not enough to matter I hope. Especially because I’m cutting small things at this point and I’m measuring from my cut location to the laser.

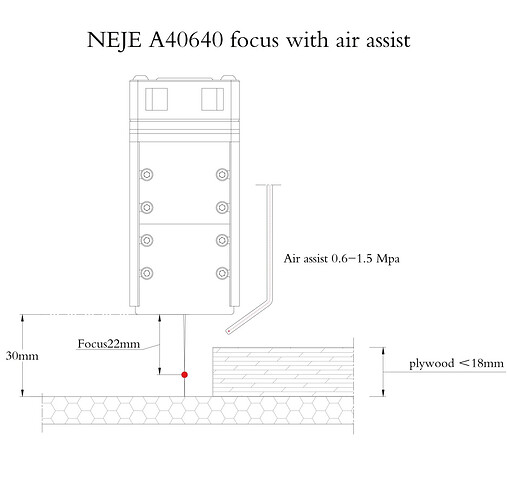

On my first attempt to cut in Lightburn (after some experimentation) I was able to cut an intricate design. The laser was at about 6mm from the material but the focus was tuned for that. It was the same 4mm hardwood mentioned above. I used these focus parameters based on a neje video I found but I think its just wrong or a different laser or something… It says to adjust the focus ring to 2.5mm (measuring from inside the laser to the focus ring back) to cut at roughly 6MM from the top of the material. This took a ton of passes and I ended up bottomed out on my Z because my bed was lower. I then lifted my bed with some scrap wood and discovered why you should not cut wood directly on top of more wood. It burns.

So, then, I suspended the wood to cut on top of the scrap wood with an air gap and it worked for the most part but I had the z almost bottomed out at -44 ish. Some areas did not burn through after like 100 passes at 85MM/s speed and 95+% power. I even bumped some things to 100% for 25 passes and they still didn’t cut but the scrap wood underneath was getting burned like crazy so I ended up having to finish it off with an exacto after it became clear something was not right.

In any case. I tried setup 4 last night.

This time my laser started 18 mm above my material focused for that surface which is lifted about 45 mm off the bed. This puts my Z at -32 so I have some room but ended up going all the way to -42mm over a bunch of passes. My power ranged from 50% to 85% and speed ranged from 50-70mm/s depending on how much detail was on that layer. I still did 40 or so passed on everything when all said and done which has me questioning why I am struggling so much to fully cut my material. It gets mostly cut but almost nothing falls out. I eventually reach a point where it seems silly to just keep running the laser over and over but its leaving a good amount of work for me to get the piece free and push out all the little cutouts (not to mention I have broken both pieces trying to get them finished up so then I have to sped time gluing). I am cutting highly detailed things as small as I think is possible (example: https://www.vecteezy.com/vector-art/12004525-interior-tree-laser-cutting-design-square-templates). I cut this last night about 70X80mm.

BUT if I try to cut something with less detail (a hexagon or oval) it cuts clean and falls out with about 5 passes.

So some questions to start:

Are you guys getting this to cut fine detail in 3 passes? I feel like the minimum I could do is 5-9 with 70%-90% power and 70mm/s speed focused at 18mm from my surface and dropping the laser about 1mm per pass.

Am I approaching making detailed cuts right? The way I’m approaching it is doing 5-6 passes at 18mm above then dropping it 2mm and running it again, drop 2, run again and so on until I see the laser going through below constantly. Even then I tend to move the laser up a bit and run again, then down a bit and run again. Over and over just trying to get as much fully cut as I can.

Why might I be having such trouble with high detail cuts but not with straighter simpler cuts? Is there a setting or something I need to mess with to help this?

I am kinda jumping all over the place and I have a thousand questions but I want to see if people respond/talk here before I keep typing.

Any advise or pointers are welcome because as I mentioned above this tool and workflow is brand new to me.