Hi there,

I am wondering if anyone has engraved a white tile with the Norton White Tile Method with the Neje Master 2S Max? if so what speed would you recommend? Thank you in advance.

I have the Neje 40w which works best at 1750mm/min @ 100%

Any slower it actually burns through the glaze and any faster I get a lot of lines.

I have only been playing with tiles for the past 2 days so also but so far that has worked for me.

Using the Offset Fill after converting JPEG to vector in Lightburn

You might find some useful information on using NWT for ceramic tile and glass in this thread…

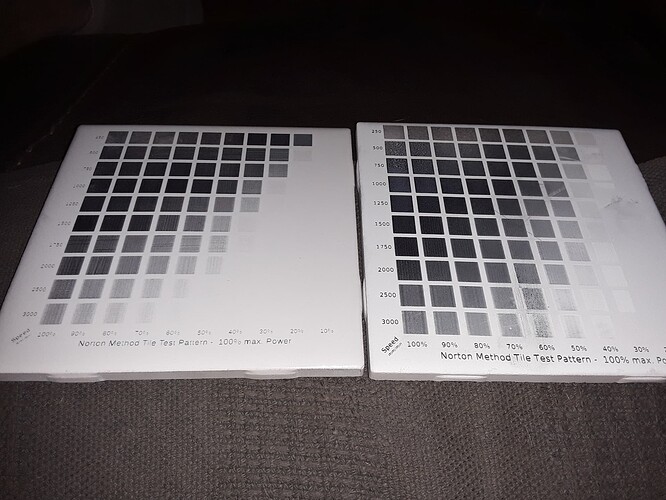

Getting the best black – using your particular laser and paint selection – is largely dependent on the power and speed you select. And the best way IMHO to determine the best values for your laser and paint is to create a test tile. Consider the following test pieces from two different lasers, using the same paint and batch of tiles… 2.3W Eleksmaker laser (left) and Fokoos 4.5W laser (right)…

This is a “standard” test matrix, with each block representing a different speed/power combination. Interestingly, quite a large range of black and grays can be had… determined solely by the speed and power used on that block. Too fast/slow and/or too much/little power and you’ll get something less than the blackest black; i.e. for both these lasers, 1500 mm/min and 90%-100% gives a nice black. Also the process can be easily “overpowered” (for lack of a better term). Look closely at the far right blocks on the right tile where the glaze has been completely removed/ablated, leaving the bare ceramic underneath. I often see blocks that are blotchy/speckled with the higher power diode lasers I have and why I prefer using my little 2.3W laser for this work. Important to note, however, is the same laser, same paint, same job run… can give wildly varying results, depending solely on the speed/power you’re using.

Using my 2.3W laser, running 1500 mm/min, 90%, 300 dpi and Jarvis dither, I easily get images like this…

– David

Thank you. Looks awesome.

My laser is 30W and the speed only goes up to 1000 speed.

That looks amazing David. Thank you so much!!

You are getting such great results David. What is your machine? i.e. what control card, interface, Marlin/GRBL etc. I am really struggling to get anything even close to yours with my Marlin/Arduino Mega/Ramps & Neje 40w set up. I am doing file transfer from my PC via SD Card. Too slow it burns through the glaze, to quick and I get all manner of missing lines and pieces of the file. I am concerned I may have a file transfer speed issue

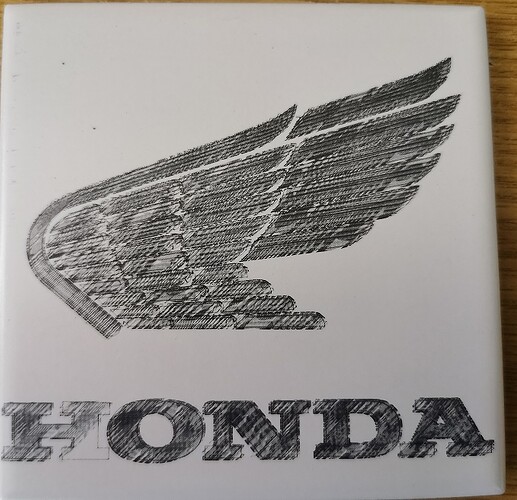

You can see part of the H was totally missed, and its not that the laser did not fire, its that it totally missed that section. It outlined ok, but did not fill. This is a vector file using fill, and flood fill enabled at 0.08mm interval 1500mm/min @ 100% 45’ scan angle

Any reason you’re running Marlin instead of GRBL on this hardware? I suspect you’d have a generally better time with a GRBL based controller than a Marlin based controller.

Additionally, one disadvantage of an 8-bit board like what you have is that it only gives you 256 levels of power vs typical 1000 for other boards. That additional granularity can be significant when working with sensitive materials. Not certain this would be a factor in your current situation.

It’s hard to tell from these photos but it looks like you may have some mechanical issues going on as well. You may want to test and tune your machine on some other material that makes it easier to see what’s going on.

Mark, my machine is about as simple as it gets… a small off-brand cantilevered machine running stock GRBL 1.1h and an Eleksmaker 2.3W laser module. I also use a RaspberryPi 3B+/CNC.js (using Jeff Eberl’s VIPi image) which allows me wireless connectivity to my Chromebook running LightBurn. I use a small personal fan gently blowing across the worksurface to clear any smoke away that could foul my laser lens.

Even more important than the machine, I think it’s best to do test tiles to determine the best black for your laser and choice of paint, as I described in my previous post. The NWT method is quite sensitive to the power and speed you use with the paint you’ve selected… and more power doesn’t necessarily get you better results; i.e. I get my best result with the little 2.3W laser than any other laser I’ve got. Note the wide variation of grays and blacks in the photos above… the test tiles from different lasers and paint. It’s not likely IMO that you’ll have much luck finding the very best setting by accident… all lasers and paint choices are different so the test tile is the way to go to find the best settings for your setup.

I use a test matrix generated IIRC by the Ortur folks…

Ortur_Power_Test.lbrn (365.0 KB)

– David

Thank you James, Py and David for your valuable time in replying.

Py, I ended up with Marlin from building my first MPCNC and have never had the need to try any thing else. I have my laser on my 1000x500mm Openbuild WorkBee which was my second machine I built.

James, you are right I do have some movement on the Z axis I see, with the speed of the engraving, it is giving issues where the slower cutting speed was not a factor (80mm/min)

David, I am making a quick mini cnc and will fit my 5.5w laser and run grbl from my laptop and see if that sorts things out. The paint side I think is finesse at this time, I need to get the basics working properly. Thank you for the link to the test file, I will definitely use that once I get the new machine going.

I am cutting some 4mm masonite board which my 15w laser seems to like to cut and modifying the files from Thingiverse (Laser Cutter/Engraver with laser cutted and 3D printed parts by ashuracode - Thingiverse) but I am finding none of the DXF files are exactly right so having to redesign them all to suit the parts I have to hand. I chose this design as it suits most of the parts I have available to make it with minimum 3d printed parts as we are currently experiencing “load shedding” every 4 hours so cant run my printers for anything more than a 3.5 hour print. Welcome to South Africa.

I have a grbl board sitting in my parts box which I have been meaning to play with, so heres the perfect time. I also have made up a SD card and screen interface for it, so will try that before hooking up the laptop.

I will keep you all informed as soon as I get GRBL running. Might take a week or so at this rate.

Mark, I feel for you, I really do, seeing as I reside in the same part of the world. And so, like you, I study the load shedding schedules carefully so that my jobs can fit in with power availability(no easy task). One day I got it wrong and realized that an imminent power outage would happen in the middle of my job. I hit the pause button, hoping that I could successfully resume once power was restored.

And I did successfully resume the job, without skipping a beat, when the power was restored. My computer runs from a 200 Ah battery, so that was OK, but my laser cutter was on the raw mains power. The problem is only getting worse so I am going to cough up the dough and put in a second 200 Ah battery.

Sigh, yep Peter, that is the world we are living in now. I have my UPS’s (3 in total) running the important things in the house and keeping the business computers running, plus one for my installation team to use on the road so they can use power tools. I don’t have spares for the multitude of what my wife calls “my toys”

Sorry to Kevin for hijacking his thread.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.