You might find some useful information on using NWT for ceramic tile and glass in this thread…

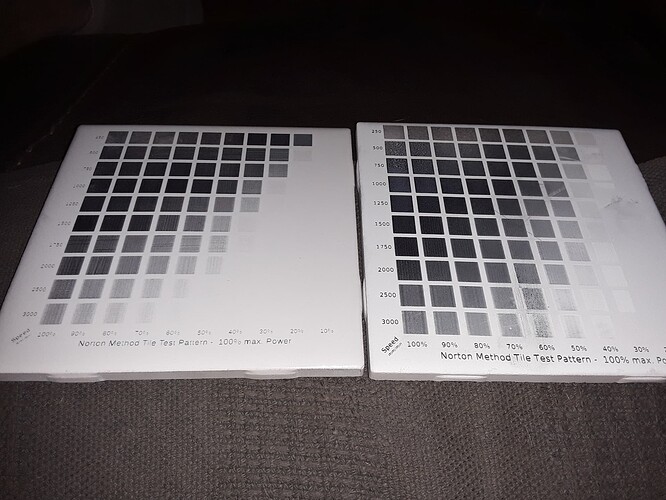

Getting the best black – using your particular laser and paint selection – is largely dependent on the power and speed you select. And the best way IMHO to determine the best values for your laser and paint is to create a test tile. Consider the following test pieces from two different lasers, using the same paint and batch of tiles… 2.3W Eleksmaker laser (left) and Fokoos 4.5W laser (right)…

This is a “standard” test matrix, with each block representing a different speed/power combination. Interestingly, quite a large range of black and grays can be had… determined solely by the speed and power used on that block. Too fast/slow and/or too much/little power and you’ll get something less than the blackest black; i.e. for both these lasers, 1500 mm/min and 90%-100% gives a nice black. Also the process can be easily “overpowered” (for lack of a better term). Look closely at the far right blocks on the right tile where the glaze has been completely removed/ablated, leaving the bare ceramic underneath. I often see blocks that are blotchy/speckled with the higher power diode lasers I have and why I prefer using my little 2.3W laser for this work. Important to note, however, is the same laser, same paint, same job run… can give wildly varying results, depending solely on the speed/power you’re using.

Using my 2.3W laser, running 1500 mm/min, 90%, 300 dpi and Jarvis dither, I easily get images like this…

– David