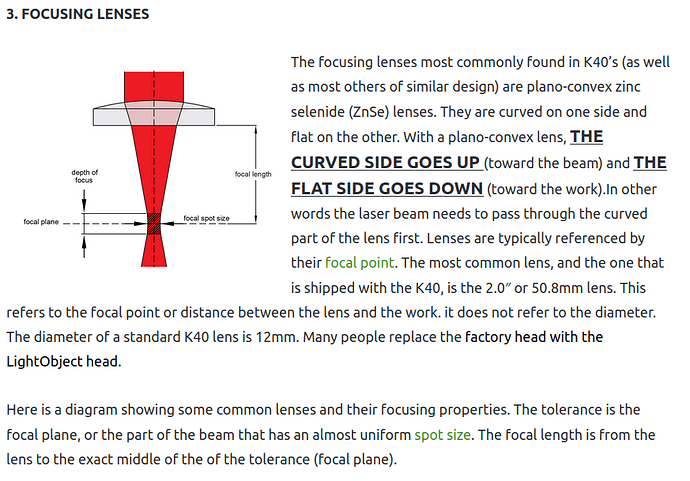

Going way back to something you said about flat side. Lens should have a concave and convex sides. Always put concave down. Nothing should look flat. If it is then the lens is defective.

Not true.

Plano lenses have a flat side.

Meniscus lenses have a curved bottom…

These are ‘cheap’ machines so most manufacturers put plano lenses in them.

![]()

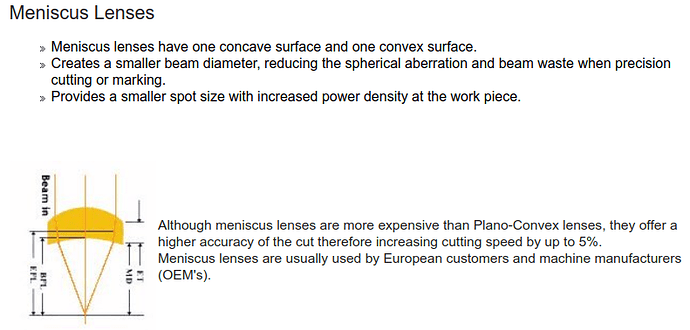

There’s a big differnece her to my laserhead as I can’t put the lens into the nozzle. The lens is mounted in the tube:

Try it without the nozzle. I’m starting to think you have a shorter focal length than 2"

![]()

Sorry, I’m not native english, maybe this was not the accurate term. Howver, as you can see in the image with my tube and nozzle (above), you can see how I installed a 5mm o-ring to get the lens moving towards the nozzle. Unfortunately there is not enough space then to mount the nozzle properly to the tube.

So the washer / o-ring idea just went to nirvana.

I agree, and will try without the nozzle - it must be below although the box says 2". But who knows

Yes… That’s common with these machines. They look identical, then you find all kinds of variations are you work your way down.

This is why most of us have changed out the original head for something that makes life with these much easier. Can’t see much of the head from the photo I posted, but this is more clear

You can see it more clear in the video.

Here’s a < 1minute video of it engraving a vector lion head… if you care…

Good luck

![]()

I have sort of the same setup with my 1.5" lens. I used the silver screw and washer above the lens and have the lens resting on the nozzle. It’ll lower it a couple of mm. I’ll get a picture of it if you want.

I have a set of different nozzles and lenses now and hope to find some time to test and experiment

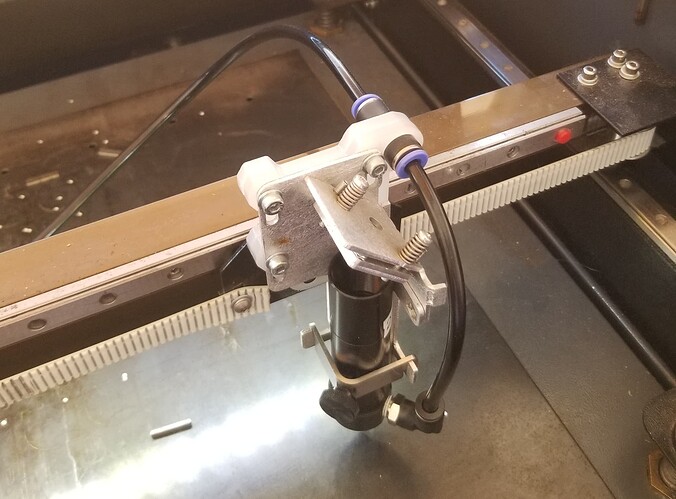

Couldn’t work too much on this, but I have tested the 2.5" lense.

The ramp test didn’t help much, I used fill (not line) this time and I measured the thinnest part of the line. Focusing on that was not accurate but I figured out the right distance, which was 16mm instead of 6mm on a 2" lense. The range of distance where it cuts seems to be smaller than with the 2" lense, but the big advantage with 2,5" lense is that I have almost no smoke when cutting and almost no residue on the wood. So, this is a big step forward for me.

A ramp test uses a single line, which is what you want…

How do you fill a line?

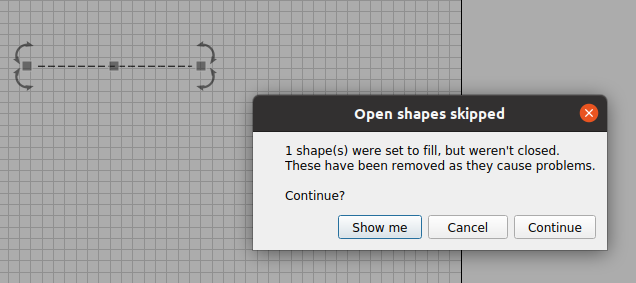

![]()

hehe. Just a line with mode = fill. Even a line is a rectangle… ![]()

If this was the case, you couldn’t cut a strip out of anything without it making two passes.

Every line is better thought of as a ‘tool path’ and is not a closed object in and of itself… meaning there is no ‘between’ area to fill.

Not only will Lightburn warn you, but it can not carry out the requested operation…

Single line when set to ‘fill’ and attempted to ‘preview’…

Your objects need to be a single line, yours don’t seem to be.

Might want to watch this video…

Good luck

![]()

When I said Lines are Rectangles as well, that was more theoretically.

What I actually did was a line with very low power, so it was more engraved. I mixed this up with fill mode. My bad.

My actual problem is still, that parts of the material are cut out very good, while others are not. Often because of glue nests, but also often without an obvious reason. It’s on different places, so not always at the same area, where you could suspect the laser path. And my laser path seems to be very good.

I think we all deal with glue pockets and so forth.

I purchase mdf that is for laser cutting and it works reasonably well.

If you’ve done the ramp test and found the focus, then you will have use a different type of material or manufacturer… you can’t predict where the glue will puddle…

![]()

I tried different vendors for plywood, all pretty much the same - more or less. It’s really disappointing, because I’m just trying to cut plywood 3mm - 6mm. With a 130 (100) Watt Reci Laser…

I understand the glue pocket problem, but I’m disappointed about such a lot of places where it doesn’t cut even without glue. MDF has no glue pockets, but I have to cut with more power because there is glue everywhere. And quickly the borders turn black.

I buy this 3mm basswood from Amazon and it’s usually pretty consistent. I have had a couple of failures in a few packages.

Mine measures out at 44W so I think you should blow through them.

Re-read some this, you’ve tried two different tubes.

However I did see where you stated it works with the old 2" but not the new 2"… is this correct?

![]()

Yes I also experiment with MDF now (had already but minor priority). To make a nice outfit, I glue wallpapers on it as the first tries some time ago were pretty good. Now taking more action on this material combination.

With the 2" lens, true, I had tried one before that didn’t work with the configuration of the old 2". I have another one now, but haven’t tried yet, as I’m pleased with the 2.5" with more distance to the material and less smoke and residue. The first tries to cut MDF were without any problems, but I used only 3mm material, 15mm/s and 70% (of 130 Watt) which makes the edges very dark. Have to see more test results. I’m still confused with the power used, so I will try less power with the 15mm/s. Maybe less power with slower cuts will also work.

br

You have some issue, I’m thinking as I cut 3mm mdf at about 20mm/s@80% which comes out to about 35W on my 44W machine.

If you view of the power is correct that means you need 91W and a slower speed for the same type of cut…

This makes no sense to me…

I think you need to find the focus or problem with the lenses before you can really go further…

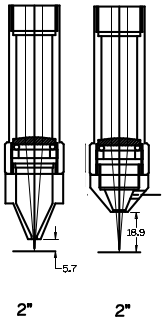

If I cut, I want it close to the material… Cutting with a 2" lens I use this nozzle configuration with 60lbs of air. The distance between the tip of the nozzle and the material is about 6mm…

I’m still thinking something is missing from the equation… ![]()

![]()

Yes, I have definitely some problems, but couldn’t figure out yet. I believe the focus is right, bed is levelled and laser path is good. One of my problems is, that I can’t invest enough time to test and focus on problem solving. Will spend some tomorrow though.

Will also try your configuration with 35% of 100W (agreed power) = 35Watt ![]() and 20mm/s. Maybe 40W for the wallpaper on both sides.

and 20mm/s. Maybe 40W for the wallpaper on both sides.

Why do you want the nozzle close to the material ?