I’ve seen a few methods for applying the TiO2 to tile, paint brush, roller, spinning, air brush, paint sprayer, pump spray, … Has anyone tried dipping the tile in the solution? Mix it up real good, immerse the tile face up in the solution, lift it back out and set it on a newspaper to dry. I ordered some and it just showed up, be a few days before I have time to try anything.

Dipping isn’t going to help. For one, you’ll need a huge volume of solution, and it’s going to coat the back too.

But all that will happen is it’s just going to be too much and create inconsistency. My best results have been making some thin plaster solution, finger-paint to make sure the whole top is wetted, then rock it from one side to the other then lay flat and microwave for 1 min. That’s basically the same thing as a dip without the mess and more control over the volume.

But it either ends up 1. too thick- where it looks amazingly well detailed and shaded and even, but then parts of it flake off on washing. Or then 2. I thin the plaster a bit more and then it ends up spotty.

There probably is a sweet spot I’m missing, I’m making gross changes back and forth and not recording measurements of what I actually mixed, and it takes awhile to burn a sample, I guess I’m getting greedy as well as sloppy and trying to do whole images that take like 2.5 hr when these tiles are so cheap I should just burn some test patterns on one side, number it, and put it in a pile.

But, small test patterns may not be that helpful since it’s about achieving consistency across the tile.

Oh hey, forgot to mention:

MAKE SURE NONE OF THAT HOT MELT GLUE IS STUCK ON BOTTOM!!

It makes it sit at an angle and the focal distance varies. Peel the glue off if you can, it’s usually not actually glued. If it won’t come off, it’s hot melt, use a lighter to melt it and wipe it off with a paper towel

Hot melt glue?

Yep they squirt some out between tiles to pad them. Sometimes stuck to the top, but usually the bottom.

It’s brittle and usually flakes off

At least the 6" Lowes white subway tiles use it

I think most of you are struggling with this process which I have found to be very easy. Read my post on the Ron Clarke method and see if you get the same results as I do. Do read all the post as it has had tips and improvements add which now give just about perfect etched tiles with just tap water to clean up. See Below

I have had pretty good luck with just dish soap and rubbing with my fingers/ thumb, tends to leave some minor residue but not to the point where it effects the image quality.

I will again attest to the value of a bright white light right above the tile when spraying, while also rotating the tile during spraying, if there are any parts that you can see the reflection of the gloss / or the tile is not entirely matte under the light then the layer is too thin. - over the last year or so I have discovered this is primarily controlled by the distance and angle the airbrush is from the workpiece.

OK, actually trying the spray bottle now. MUCH MUCH better!

Lots of thoughts:

Although I saw online that TiO2 is supposed to be very soluble in ethanol, it’s not. Basically zero. I got some results by shaking before pumping, dried real fast, nice

The water/TiO2 mix can do a pretty wide range. But, whatever I do, I kept getting the following:

Each pump must be a hard, fast squeeze to avoid spattering. Good idea to point the first squeeze away to avoid spatter.

But any way you do this, it is never going to make a fine mist. It will land and dry as droplets.

Attempting to make one continuous sheet layer like you would with paint tended to just streak and crack up as it dries.

But, here’s the key- never go that far. Mist it down, not enough for droplets to merge. It will be blotchy when it dries. Light mist again. If you do too much at once, it will dissolve and move the prior layers.

As has been said, look at it at like 45 deg with a light source on the opposite side. If you see ANY spot of glossy tile, that will not burn black. As long as you see matte surface, you don’t need more.

This suddenly burns WAY faster. Very black at 50mm/s. Was 10mm/s with spray paint.

Washes off easily. Surprised I wasn’t clogging the spray bottle.

Wasn’t using PVA glue. Started to work on another idea that I think is better.

PVA white glue is “polyvinyl acetate”.

There is also PVA “polyvinyl alcohol”, PVAl, used as mold release for castings. It covers even very slick surfaces well, dries fast, water takes it right off- much easier than PVAc. Or it just peels off. They used to sell one with purple color at Hobby Lobby, I have an old one.

Polyvinyl alcohol might be pretty useful, I didn’t get a chance to try it fully. It could have a key advantage over PVAc glue in that it washes off much easier. But just water and TiO2 is working pretty excellent, the only prob I’d want to try to “solve” is being able to lay down a whole wet sheet layer instead of misting over and over.

The layers can be very consistent and burn a million times better and clean easily with just TiO2 and water. The only complaint is having to do like 5 coats.

I got this to go way faster by microwaving the tile. The mist droplets land and evaporate in like a minute and you can hit it again.

Perfectly dry tile does not get very hot in the microwave. Wet the back first, let it soak, unglazed ceramic is porous. It’ll get super hot and that’s best, each coat flash-dries. You can also dry a coat in the microwave.

At 50 mm/s, the LI went back down to 0.1mm. It’s pretty great! However, the shading has some issues, I think now it needs that Dot Width Correction which it did not need before.

I use water with an air brush to get a fine mist… I also add a little food coloring so I can see the ‘coat’ that I laying down…

The food coloring separates, don’t know what’s in it, but it will separate with just it, water and TiO2…

I don’t know if you’ve tried LBT100 spray … water soluble and non toxic, they claim… it’s rather pricey, but I like to use it on tile and stainless steel mugs, like this one…

lbt100-settins.pdf.txt (96.0 KB)

They specify the thinnest coat possible. This make for good blacks at low power. The thicker the coat the more power, loss of dark blacks and a lower resolution…

Good luck…

![]()

A few more points after more attempts:

- Water can hold WAY more TiO2 than you’d think. I just kept adding more and more and never hit a limit

- the spray bottle casts WAY further than you think. It’s terrifying. I was behind the house in the dark with just a headlamp, which was actually working out well for seeing coverage. Minutes later, I can still see droplets in the air, even like 20 ft away.

- It IS possible to do it with one coat, but I’ve had successes and failures and I’m not sure why. I think the formula is get it hot, give it a couple of pumps, it steams off but still hot, give it a bit more…

OK I may be on to something here- what’s a liquid media that leaves no residue and dries streak-free on glass and tile surfaces?

Oh yeah- Windex!!!

Working on this. I think I’m getting a pretty good case for a solution you can just squirt on rock back and forth, and dry in place. Some things need to be worked out.

Bubbles are surprisingly a deal-breaker. After shaking to mix it, foamed up so much the straw couldn’t find liquid and stuck with the pump handle in, so I can’t pump to clear it. When I shift the tile back and forth to level it, the bubbles actually carve a path into the thickness I’m trying to keep constant.

But it makes a smooth liquid sheet and does not contract into droplets when drying. I think this is going to be the winner, this experiment just needs work on how to handle it.

Going off Wikipedia, it used to be 4% ammonia, now:

4.0% isopropyl alcohol, 1% ethylene glycol monobutyl ether, 0.1% sodium lauryl sulfate surfactant, calcium 0.01%, tetrasodium pyrophosphate (a water softener), 0.05% of 28% ammonia, 1% of a dye solution, and 0.01% perfume.

So, nothing that leaves reside. Cheap, available anywhere.

I’m not sure how to apply to curved surfaces without an airbrush. I’m seeing the paradox here. We need it to be a complete layer but one that won’t run. If it’s too thick to run, then it won’t be of consistent thickness. Once you thin it enough to self-level on a tile, well, you can’t self-level on curved surfaces.

Also, I think I got some tile which might have been perfect late last night, but I left them on the deck and, oh yeah, morning dew. Dew droplets redistributed the layer.

Sounds like a good approach… Keep us updated…

![]()

The polyvinyl alcohol really does look the most promising, but not the most cheap/convenient.

The windex is pretty good except it foams easily, and I get bubbles in the layer even when using a spray bottle. I got pretty good results just pouring it, making something that doesn’t involve TiO2 getting misted around is one of my goals. I realized I chalked quite a lot of my backyard and I don’t know how long that will take to go away. Poured, rock the tile back and forth, got to a good place, but it still wouldn’t dry for a long time at a pleasant ~70F outside. Could use a heat gun or microwave the tile.

I think I was in the wrong place with the water and too much TiO2. It wasn’t that it didn’t dissolve, and didn’t clog the sprayer, but with less TiO2 I got a much finer mist. What I was doing sprayed, but the droplets were way too big. I don’t have actual measurements of what went into either mix.

I’m getting the best results with hot tile- like, clean the front with acetone, wet the back, microwave for 2 min. Super hot, you can’t hold by hand. Sprayed with more dilute water/TiO2 mix, it dries off as it hits, and I got a complete layer in 1 coat.

Also, tried misting the tile with 3M spray adhesive beforehand. Just to make it so water won’t bead up on it. May have helped

Just a thought. Have you tried a spray bottle for perfume ? I think they are called spritzers and spray a very fine mist.

Has anyone tried using an additive like Floetrol?

I really helps smooth out paint. I tried it this summer for the first time on kitchen cabinet doors and I was amazed. Got the latex version at Lowe’s.

My thoughts are it may assist in providing a consistent thickness since it’s purpose is to help level the water based latex paint.

Looks like the big box hardware stores carry it.

I use that fairly often for painting.

Essentially it is used to reduce the viscosity of latex (better for spraying) and to reduce the surface tension.

It will not really dry as-is and should only be used as an additive, but it is an intriguing idea!

Yes, as an additive only to do just what you and I describe.

I have no idea if it would work, i.e., my laser is down at the moment for upgrades.

I learned many things from this thread. This is the method I arrived at:

I mix up the paint myself. I take a food blender. Pour in:

- 175ml water – water based paint, so takes an hour to dry

- 25 ml ethanol (denatured) – solvent and preservative

- 0.25g glycerol – to help the paint to stick to the tile

I close the lid, start the blender and from the top opening add gradually:

- 0.5g xanthan gum – to help suspend the TiO2 in the paint liquid. good amount is probably 0.5g-1.0g (0.25…0.5%).

- 50g TiO2 – ~20% oxide content in the paint

- 5 drops of food coloring – to help seeing where the paint goes during spraying

This results in about 250ml of paint. Good for about 40-80 15x15cm tiles. If it has been sitting around I’ll give it a firm shake before usage.

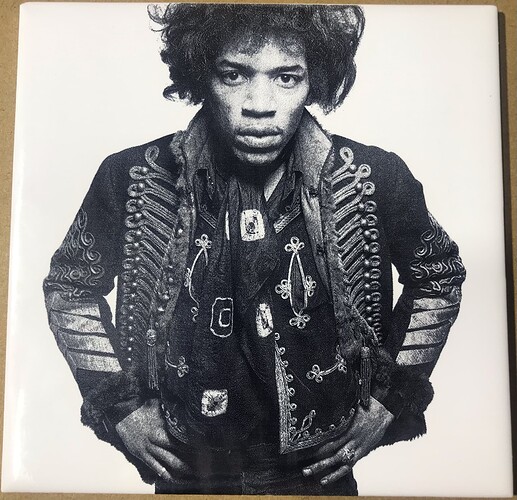

Then I got a cheapo small paint gun from the hardware store (120ml cup, gravity feed). You’ll need an air compressor of course as well. I spray the tiles with a thin coat and let them dry for an hour or two. Please use a respirator when you do this yourself. The results are very good – uniform coating, solid blacks, clear lines. The hardest part is cleaning the paint gun.

Paint can be easily washed off and the tools cleaned using warm water and soap/dish detergent. No toxic chemicals in the paint.

Some of the problems I’ve had:

Cleaning the tiles before painting. It appears the suction cups in the factory that are used to move the tiles leave a residue that does not easily come off. I got small rings in the middle of tiles where the paint does not adhere. I’ve tried all the solvents/cleaners. Need a lot of hard scrubbing to get it clean. The paint pulls away from the dirty areas. Adding more glycerol into the paint mix might help against that but it’s probably better to clean em properly.

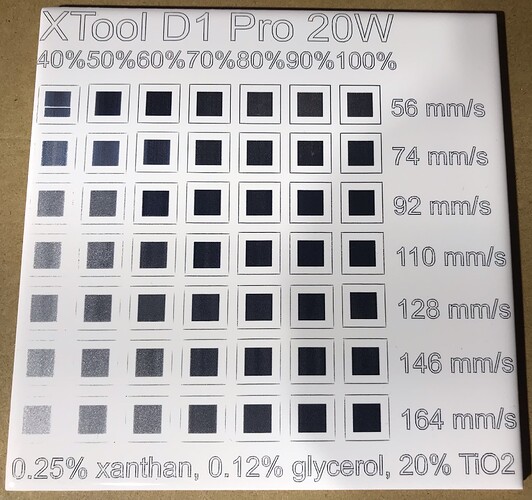

My xTool D1 Pro 20W seems to be underpowered – at places where velocity changes the engraving quality deteriorates, especially movement along the Y axis. I’ll try to upgrade the power supply to see if that helps. Horizontal fill works well though. I fill engrave at about 110 mm/s at this moment.

I had to adjust the fill line interval to get a more solid result. D1 Pro 20W is rated at 0.1mm output size but the blacks are more like 0.065mm wide.

In my first try I used 2% xanthan solution and a medical spray bottle. And a lot more ethanol. The result ended up flaking off during engraving. Adding glycerol fixed that but the result wasn’t too good – came out more gray than black.

My second try was 0.5% xanthan/0.5% glycerol/10% TiO2. This worked a lot better but still was grayish, especially if the coating was thin. Could be the problem was just too little TiO2. But note that glycerol is hygroscopic so could be it interfered with the burn by tying too much water into the mix.

The recipe here is my third try – 0.25% xanthan, 0.125% glycerol, 20% TiO2. It’s probably not perfect. But it works. The usual disclaimer: this is my first laser, my first time trying to make paint, my first time using a paint gun – exercise caution when following random stranger’s advice on the Internet.

This is quite a bit of work, but it does provide a consistent result and allows to scale for larger production. But if you just want to try couple of tiles – get a small 100ml transparent medical disinfectant spray bottle (from drug store, 80% ethanol v/v), add some TiO2 powder, some food coloring, shake, spray the tile, wait 2 minutes – and you’re done. Results can be pretty good if a bit inconsistent. Don’t forget to shake. And the spray bottle will likely clog eventually. But for couple of tiles to play with, it works very well.

Thanks again. It has been a fun Christmas/new year’s project.

The error at top left was caused by me stumbling and bumping into the machine enclosure. Sorry about that ![]()

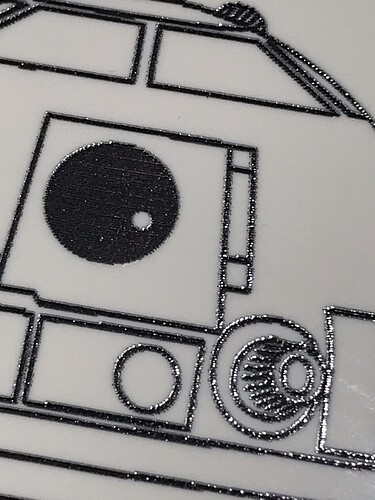

A closeup of another piece I did. This must be the adamantine/metallic luster of black rutile (or is it anatase?):