My first spray not so good. I washed the 6" tile with 91% IPA and flushed the spray gun with 91% followed by a water flush. I am not a spray gun person, other than spraying latex on the walls, and I really need help adjusting the gun air and liquid metering. Water & TiO2 ratios would help. IPA in the mix is too problematic. Gum Arabic was about .007% in the mix.

Found this. Now I just have to calculate how many grams of Gum Arabic are in 3 drops of water.

Gum arabic is the basis of the best watercolors. It can be used to create interesting textural effects when mixed with watercolor washes. Useful in making emulsions with egg tempera and resins.

Prepared Gum Arabic Recipe

Ingredients

300 grams (10.5 oz) Gum Arabic powder

3 drops Clove Oil (optional)

1 liter (2.1 pints) of distilled water

The ratio is 1 part gum to 2 parts water. Boil water (or use distilled water) and allow to cool to about 140° F (60° C) and then add the powdered gum, stirring to make sure there are no lumps. Continue warming the mixture at that temperature and stirring to dissolve the gum arabic completely.

Add drops of Clove Oil to extend shelflife. Prepared Gum Arabic must be stored in the refrigerator to deter mold growth. It may be advisable to make small batches so the solution will be fresh rather than storing larger quantities for an extended period of time.

UPDATE:

Gum Arabic is off the table. I was shooting for a 1:2 ratio to water. I figured it was by volume because 2 parts water=150 grams and 1-part 50 grams, being a 1:3 ratio by weight. I heated the water in a pint Mason jar, then scooped up a heaping plastic spoon (about 7-8 grams) and dumped it in the hot water. The mixture immediately jelled and my mixer would not even move. I kept adding hot water until the jar was full and still could not get a complete mix. I put a lid on the jar and put it in the trash.

I tried a foam brush on the tile and got poor results with that, I think the alcohol evaporating caused the liquid to move and puddle. I think the spray (image above) did the same thing, only finer.

Bottom line is I do not think all these additives are worth the trouble. I believe @jkwilborn said it best+ Water, TiO2, and a dash of food coloring.

A couple of questions…

What lead you to heat it up with water?

Where did you get the 1:2 mixture value?

@BillieRuben advised it takes a very small amount… a couple drops… Which correlates to what I’ve read about it…

I haven’t tried it yet with the gum Arabic, so I don’t know what to expect either… I would suspect you are using too much gum from your numbers…

Will let you know when I get the time … will be tied up for a few days…

Good luck

![]()

Definitely use cold water (I’d worry about the gum denaturing at high temps, it’s a natural product after all). And Mickey, that’s definitely way too much gum. Get your liquid gum arabic (either pre-mixed e.g. by Winsor and Newton, or powdered and mixed with water to roughly the viscosity of vegetable oil). Then add a few (say 4?) drops of this liquid to a tablespoon or so of pigment, then add water to form a thin paste/paint of your desired consistency (again, I’d say roughly the viscosity of vegetable oil). I’d also leave out the clove oil, for fear it will mess with the surface tension. Just let the paint dry out in a shallow dish (watchglass, saucer, etc) between uses, and reconstitute with water when next needed. This should keep it from getting mouldy. If you have a 3D printer, you can speed up evaporation by placing the dish on a warm 3D printer bed (say 60c or so).

spray it again. I keep it flat and spray it to the point that it would run if it were normal paint. that is the way I get my best results. It does not spray out well and you need a lot on the tile to flood and get a level material application. I typically do two sprays. I know it is not the quickest and the easiest but it has given me the best most consistent results.

also always do a test tile. I spray in batches and if I spray them all the same, hopefully, the test will be a good representation of what the other tiles do. to not waste a tile I usually make something that is a fill and not a gradient so i cant see if the black is nice and solid and deep in color. If it is I know that I have good tiles to do my more complicated burns.

The recipe listed above. Does this mean I can’t trust everything I read on the internet?

Mickey is the rich mouse in Orlando. I agree, but nobody seems to know the proper mix using powdered gum.

Like how many grams in a pint of water?

That was my mistake. I tried to coat the tile as if I were using normal paint.

Just one this time to lock in the spraying part.

Thanks to ALL for the feedback! I am going to leave out the gum until @jkwilborn says it helps. @BillieRuben 's suggestion for cold water makes sense. And Spray Like a Beginner looks like what @james.myatt is suggesting.

Jeeze I love this forum!!!

This had me confused as to why you’d want texture when doing NWTM and should have brought it up…

Texture can mean a lot of things. The Gum Arabic was introduced by someone else, I was just researching it, not trying to be the authority. Textural effects can mean changing glossy to flat. I don’t think anyone here was expecting to put lumps in the spray. We keep bouncing around my original, and others, question, “What and how much of each?” Bits and pieces are sprinkled throughout these 348 messages, and other threads too, but I have not managed to locate a stable and repeatable mix formula.

Just saying that I found the link from which your recipe from(https://www.naturalpigments.com/gum-arabic-powder.html ) and the goal of post mentions creating textures and emulsions which is likely why it mentioned using so much of the gum arabic. And maybe it’s so they sell more of it. ![]()

Personally, when experimenting, I add stuff slowly and observe results since for some reason one persons ‘cook book’ doesn’t always seem to work the same when I ‘cook’. I’m hopeful this Gum Arabic becomes THE way to create a good brush-on coating since it’ll wash off easy and we can just let it dry then add water and mix again later for another use.

Yes, that looks like that was it, but no matter. Info was no good for our application.

Found a Forum posting with a lot of detail using TiO2 and water…

Hi Uncle Ron ! Hope you are keeping well and busy. I’ve not been doing any engraving until recently as I bought a new AtomStack A10 Pro machine and started again. I tried a new recommendation using Denature Ethanol 95% alcohol and mix with TiO2. It worked but this method I cannot touch the tile or it will remove the coating. Anyway I tried something interesting yesterday. Using the same process and added 2 teaspoon of PVA wood glue and mix it thoroughly before applying to the tiles. When dried it stayed on the tile and do not get removed easily unless I wash it. When doing engraving the end result looks OK. I only need one layer. My engraving end result was darker than normal even when using. Speed: 2800 and Power: 40%, so I will have to use lesser TiO2 powder.

Hi Jack ! Hope you are keeping well and busy. I’ve not been doing any engraving until recently as I bought a new AtomStack A10 Pro machine and started again. I tried a new recommendation using Denature Ethanol 95% alcohol and mix with TiO2. It worked but this method I cannot touch the tile or it will remove the coating. Anyway I tried something interesting yesterday. Using the same process and added 2 teaspoon of PVA wood glue and mix it thoroughly before applying to the tiles. When dried it stayed on the tile and do not get removed easily unless I wash it. When doing engraving the end result looks OK. I only need one layer. My engraving end result was darker than normal even when using. Speed: 2800 and Power: 40%, so I will have to use lesser TiO2 powder.

I’m glad to hear you have found a method that pleases you. After all that is the most important objective. Personally I have stopped experimenting with tiles etc. And even at this ripe old age have decided to spend most of my time learning more about lightburn and all its fantastic caperbilitys. I’m currently following Rick, the L A Hobby guy on YouTube. I watch his videos and then practice what he says. Keeps my old brain active and me out from under the wife’s feet. ![]() Nice to hear from you, cheers Ron.

Nice to hear from you, cheers Ron.

Thank you Ron. Glad to know you are keeping well. I’ve also subscribed to LA Hobby and they have interesting Things where I also learn. Enjoy what you’re doing.

I Uncle Ron. Need your advice please. I have been using my new Atomstack A10 Pro and doing ceramic engraving which work and have no problems. Unfortunately in the last engraving the laser engraver head lock screw when loose and slide down to the base and stopped. I Log out and log in again with the intention of doing engraving from the beginning. The Engraving machine seem to be working properly but it is not engraving. Initially I thought the tile that’s coated with TiO2 needed to have additional layers which I did added but it still do not burn. I tried another test using a tile coated with Rust Oleum paint but it also have the same problem. Is this LightBurn software issue. Look forward to any of your advice please. Thank you.

Difficult to say what the problem is and sorry to hear of your accident. First I would disconnect the Lazer machine from the computer with both turned off. After a few minutes which allows the capacitors in your controller to discharge reconnect everything and test the Lazer with something simple like a small circle on a bit of scrap material. If all’s well proceed as before. If the Lazer doesn’t draw the circle I would talk to lightnurn staff. My gut instinct is the controller has lost control of your machine and the above should reset it. Do let me know if you get it working. I’ve had a similar problem when I carelessly moved the head while paused and it crashed into the frame when I restarted it.

Good morning Uncle Ron ! Hope you had a great weekend. Mine weekend was great until this problem came up. I’ll try out and keep you informed.

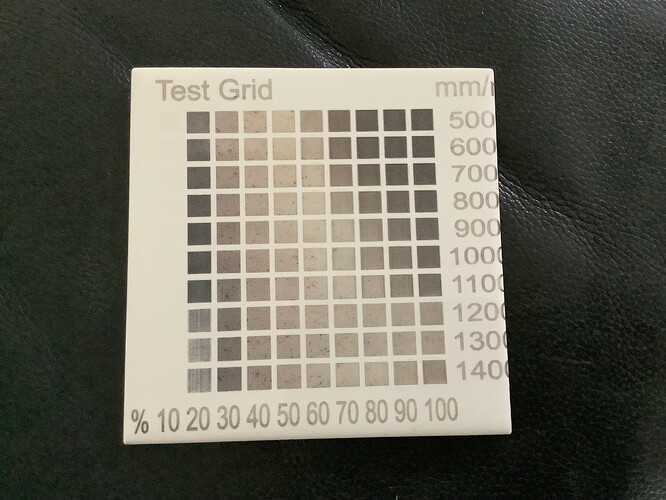

Hi there im new to lasers and engraving having just recently got my xtool D1 Pro. I made up a mix of Duluxe colour Oxide water glue and 2 drops of dishwashing liquid and have ran the test grid and attached it, could you give me advice on if the test looks ok and correct and which setting speed/power looks the best for when I burn an image on the tile. Thank you in Advance