is it TiO2 pigments or FeO pigments?

Also has anyone else tried with iron oxide instead of titanium oxide?

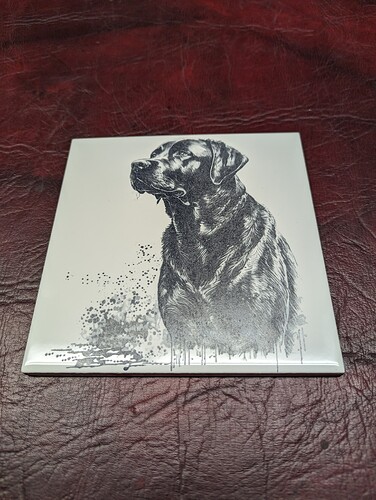

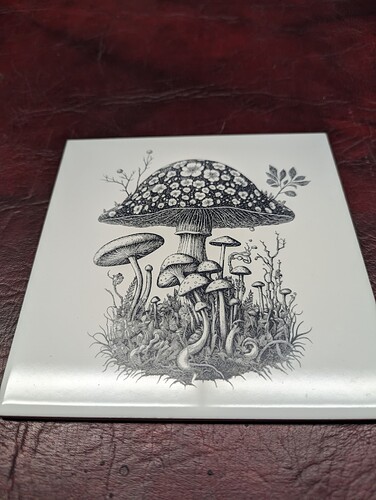

I have had good results on ceramic tile using Titanium Dioxide with Isopropyl Alcohol mixed in a spray bottle. I spray two thin coats with a 10 minute interval, tile is ready for engraving in total of 20-30 minutes…the alcohol evaporates quickly leaving a matte finish white coating. Run under the tap when finished to rinse off the coating.

Hi I’ve noticed somewhere on here you mention you’re using a fibre laser to engrave glass can this be done by painting the glass and if so what settings please buddy?

Not glass, it won’t work on visually clear items very well. It should work with some kind of indirect method.

If I need this I use the co2, so I wouldn’t have any clue as to what starting values for doing this would be.

In simple terms, the wrong machine for the material.

Let us know what you find out.

![]()

What do you mean I direct method?

If the laser frequency will not excite the material, such as a visible light laser using clear glass or acrylic. you have to use an indirect method.

This is usually painting it black, where the heat from the black coating gets hot and that heat works on the target material. Same on acrylic with a ssl (solid state l) or diode laser, the dark pigments in the dark acrylic is heated, it won’t excited acrylic.

Make sense?

![]()

I tried two types of Titanium Dioxide with a UV galvo on stainless steel (food grade and another). Going slower was the only way to get black.

Just an FYI for anyone using a UV.

Ye that’s Great thanks

Use a USB Microscope, and you will clearly see the surface of the glaze is being melted by the laser and the TiO2 is fusing with the glaze.

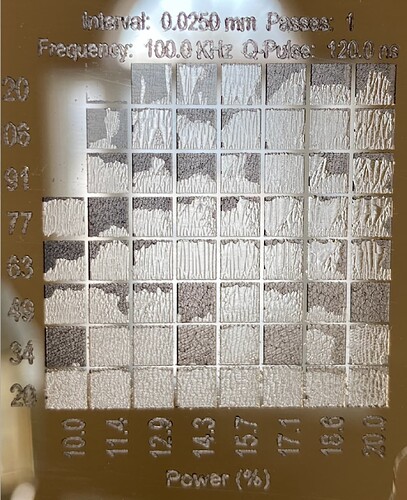

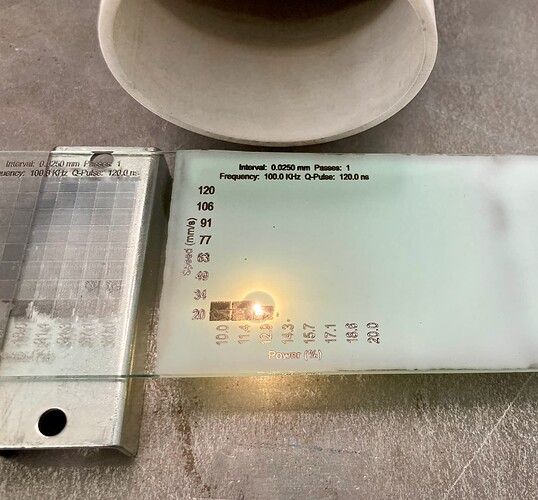

I have been experimenting with glass and TiO2-PVA mixture (Ron’s recipe) with a 60W fiber laser. The TiO2 seems to adhere to the glass and peel the top surface. Running a second pass with the laser detaches the TiO2 “flake” leaving an interesting finish on the glass. Still trying to workout the details. Here is a picture of the material test results with settings. Note the different glass textures at different speeds. Speed range is 20-120mm/s and power is 10-20%. Using a 175mm lens.

Ooh, that’s really pretty! It reminds me of glue-chipping: https://youtu.be/P_g_eTXATKg

Cool. I have never seen that process before. Indeed some of the panels have a similar effect. I may need to play with this a bit more to see if we can get repeatable results. Thanks for the link and information.

`I have gone through almost 100 tiles perfecting my method and I have discovered it’s a combination of the quality of the coating and the exposure/speed combo.

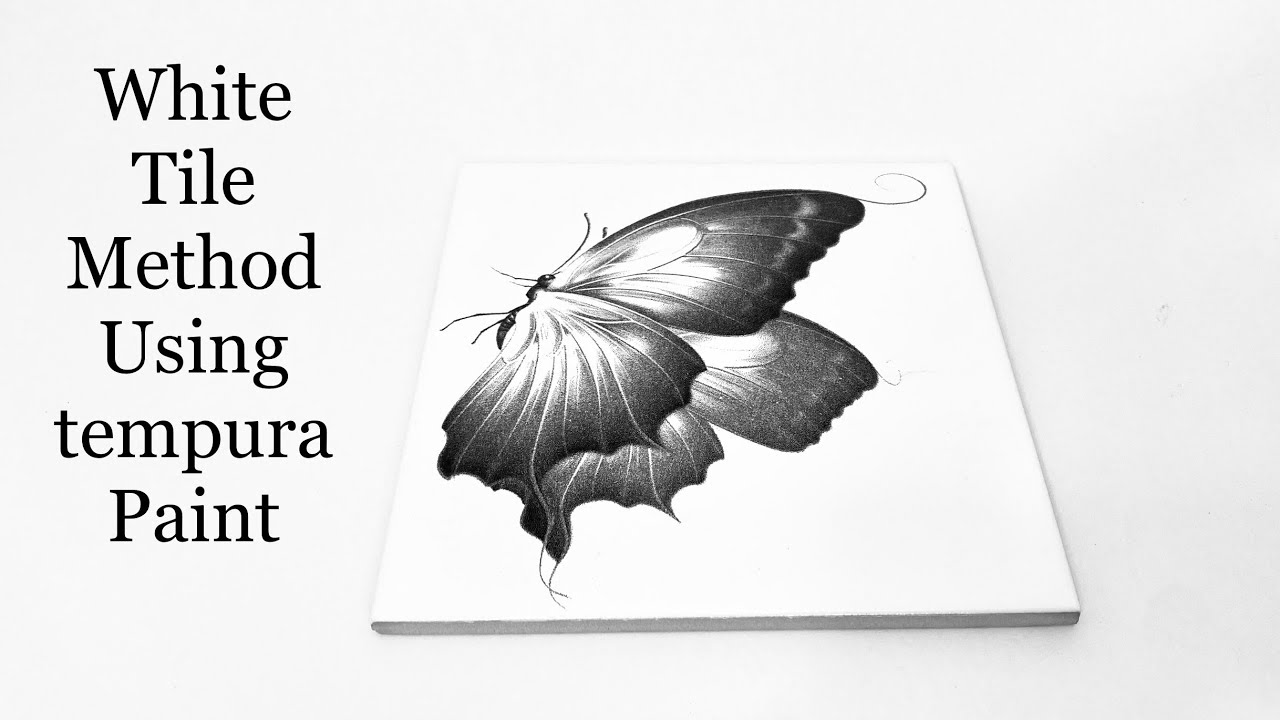

I was looking for a water washable yet quick drying medium to mix with the TI02 I tried Acrylic but a PIA to remove, the school glue was a joke, and alcohol didn’t keep the pigment in suspension and was extremely fragile, but I finally selected white tempera (school grade) which was ALMOST perfect. After realizing white pigment mixed in white tempera on white tile was pretty lame, I broke open the piggy bank and purchased a quart of some green tempera for a few bucks… Perfect! It produces enough color to indicate the coverage and quality of the coating.

I tried foam brushes, foam rollers and finally dragged out the air brush. One of my brushes is a Patriot 105, which is perfect for laying down a moderate coat. I have a desktop spray booth with extractor which works for spraying 4 x 4" tiles on a turntable. I have experienced NO CLOGGING running 35 lbs and pinching the tip occasionally. I lay down 2 or 3 coats per tile and then let them set for a few minutes and transfer all 4 to a toaster oven set to 110 F for final drying in 5 to 10 minutes.

I use 1 part tempera to 2 parts TiO2 and use and place in small dropper bottles. I blend for 30 seconds with an agitator and experience no separation during painting. I add the mix to the paint reservoir and thin by adding distilled water til the mix is the consistency of cream, maybe a shade thinner. I stirr with a small paint brush and have been getting repeatable, dependable results.

I tried various spray bottles as well, always clogged and pretty poor spray patterns, and a cheap battery operated air brush which was total junk. I’m afraid the airbrush is a corner you just can’t cut, but you can purchase some pretty inexpensive air brushes and possibly (I haven’t tried this one at home kids) your air assist compressor might put out enough pressure to run the brush.

Bob

i basically do the same thing, you are much more scientific than i am. I use a few drops of black tempura paint to make mine a light gray to see where i have painted. I use a cheap spray gun from harnbor freight. two coats and i am good to go.

here is a very crappy video if anyone is interested.

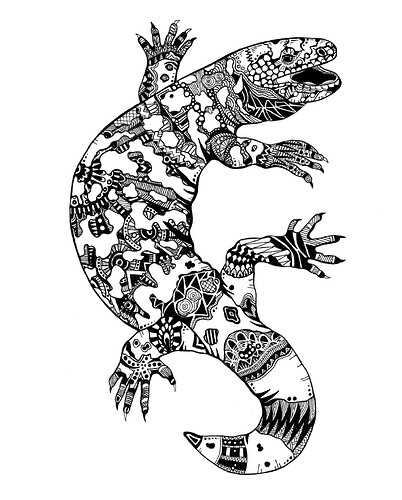

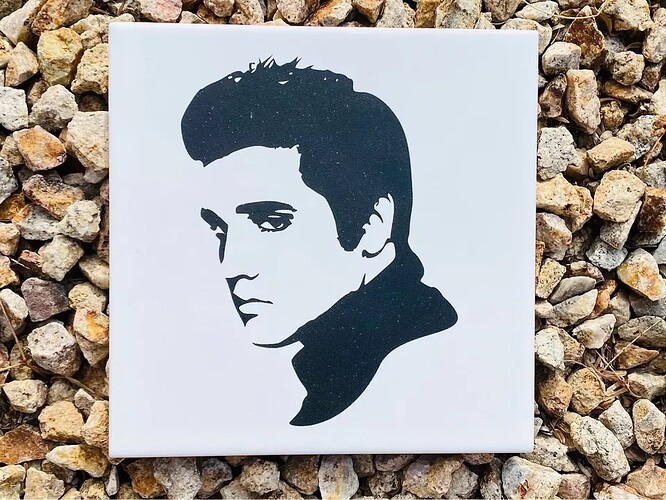

I tried the same spray gun and I got the same uneven results. The spray is too coarse and produces surface defects. I use 1part tempera to two parts TiO2 and then that mix is diluted with distilled water 1:1 ± and a get an absolutely smooth even coat with no surface defects as you can see from the Gila monster. Not scientific, after 80 or 90 fails, I eventually got it right! To produce commercial quality images, it has to be perfect.

Bob

Is that image public domain? I kind of like it…

![]()

Not sure, I am only using it for testing and have been giving away the acceptable tiles to friends.

Do a search for Gila Monster. its a good test image for even coatings, no pock marks and solid blacks…

watching the video above it is 2 Table spoons Paint (40ml) , 2 teaspoons TiO2 (12ml) , 6 Tablespoons water (120ml ) and spray using a spray gun , ill give that a go . The only good result i have had was with a spray gun , brushing was pretty bad , too thick and too many brush marks , probably because i’m 10x better at spray painting

Haven’t gone all the way down this long thread yet but having the same problem. Getting no color with titanium mix so tried spraying with white paint and got good results with same power settings for both.

It looks like you have excellent results. Could you please tell us what type of laser you are using, specifically CO2 or diode? And maybe speed and power. I sure would like to get results like that. Thanks for sharing.

John Davis

5watt Diode & 50watt co2