On manual ones, we often adjust focus by just running it and jogging the handle up and down a bit by hand to get the “biggest spark”. On metal, there’s a bluish white like that appears and it’s audibly loud. I might create a test patch that is made intentionally slow to give time to find the focus. But TBH most often it’s been doing like a coin and the first pass usually won’t be a final surface layer, so I might be hunting for focus while doing the first layer. I might restart several times anyhow if I don’t like the parameters. A single layer is very thin and it’s not likely to show up in the coin.

You have safety goggles, right?

On manual models, there’s that pair of red laser pointers that converge when focused. It can only be set for one focal length and kind of a pain to recalibrate. When I changed to another lens, I couldn’t use them. I wanted to use the ruler scale on the z-lift but you have to calc the offset between the scale pointer and the actual focal height with a shorter lens, and the work height. But the offset will actually change some when you go change the lens too because the lens thickness is different. So it’s only “ballpark” and needs manual

You do need the manual for “YDFLP-E2-60-M7-M-R” specifically. You can email JPT for it- in my case they wanted the exact serial number on that label too to give me a manual for it.

Reason being, there are only ~17 defined q-pulse lengths. If you enter a number that is not defined, it will round off to one that is defined. Each q-pulse has a max freq and a “cutoff frequency”- below the cutoff, the pulse profiles are fixed and adding more freq just gets you more net power (not to be confused with the “Power” field). The net power from the machine peaks at the cutoff freq. AFAIK that should be 60W for your machine if you had a power meter on the output, for any q-pulse.

But above the cutoff freq, the machine throttles back its net power output with increasing freq. AFAIK it does this by internally capping the “Power” field, and if you hadn’t entered 100% in Power anyways, it might still be under the cap- but that’s untested.

Without that mfg chart, you won’t know which pulse you’re selecting or if you’re getting limited. That will confound your attempts to do materials testing. Material testing in LB really can’t sweep q-pulse on an axis because the q-pulse types are spaced irregularly.

I can easily hit a “melt limit” on mine, esp in raster scans. If the surface temp gets too high, the beam actually stops cutting. Part of the scan line will go from bluish-white to orange and there’s not as much spark. The beam doesn’t really vaporize a chip by boiling metal, it explodes it with the shock and a chip flies off. My best understanding is if the surface is near melting, it will be too plastic and absorbs the explosion instead of throwing off a chip as a spark. It can also melt completely and flow and fill in what you’re trying to cut.

The net surface heat is a factor of 3 things- within a raster line, the overlap of heat from the last pulse or pulses leading up to it. If the pulse spacing is similar to the spot size, there is little overlap and this is minimal. Second is overlap from the heat of the prior line. It’s generally not significant if you use rotation. If you don’t use rotation and line interval is smaller than the focal spot size, then it can sometimes be very significant. And, net heating of the coin blank can happen. I’ve gone way too far and gotten them to glow. This didn’t generally happen in ranges which were actually successful at all with engraving though.

Overheating may not show up for the first few passes, until heat builds up. It it going to be worse in the early layers of 3d layers because those are almost always firing for every pixel. The behavior is really inconsistent in this range too, because the time spent to get from one raster line to the next varies depending on width.

It’s not JUST the overheating though- I see “splashing”, esp in aluminum, where the ejected particle- which is going to be a liquid state- doesn’t eject over the top, it gets blown out of the center of the mark but sticks on the edge of the cut and it just builds up and makes a rough edge. On my 300W, that was easy to do. I think it’s best to go with a smaller q-pulse to avoid this.

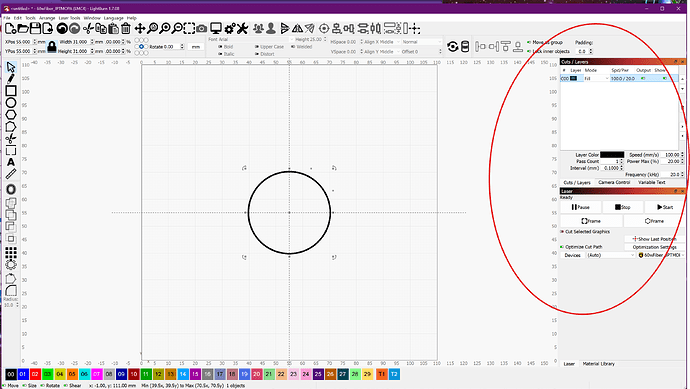

The 110x110 lens is probably going to be your go-to lens for coins and most other things. The Line Interval should be about 0.015-0.030. The lens’s focal spot size comes from a physics rule on lens diffraction- twice the focal length means twice the spot size. The beam can’t focus smaller than the FSS.

However, the actual Mark Spot Size (MSS) is the size of the cut made is different- a bigger pulse makes a bigger spot.

One thing it took awhile to notice is that we can cut within a single line in “single-spot mode” or “multi-spot overlap mode”- I made that up term for it, I don’t know if there’s anything to look up about it.

The length of the q-pulse in time is generally insignificant. At 7000mm/s, 100ns covers 0.0007mm, much smaller than the FSS. But the resulting MSS will be like 0.015-0.030.

Within a line, be VERY aware of pulse spacing, which is just speed/freq. In general I’ve gotten the best success with “square pattern”- pulse spacing is equal to LI.

The “single spot mode” is if you select a q-pulse that isn’t above the energy threshold that will mark the material, AND speed is high enough that the FSS doesn’t overlap, you get no mark. But you can get a mark where the pulses overlap. The first pulse in a line creates no mark, only localized heat. If speed/freq is greater than the FSS, the next pulse doesn’t overlap, so there’s a whole wide range where it does nothing. But if the next pulse does overlap, then the second pulse can make a mark where the energy of the second pulse overlaps the first. As you go higher freq and/or lower speed, 3 or more pulses can overlap within an FSS.

So far my best recommendation has roughly been:

- LI be the MSS, 0.015-0.030 for a 110x110 lens. So the line basically doesn’t overlap.

- Go “single pulse mode”, pulse spacing ( speed/freq) is the MSS. I’ve gotten some decent results with pulse spacing half that, though. But it seems worse for the amount of heat generated vs the actual chip size.

- Keep “Power” at 100%, and control the pulse energy primarily by q-pulse selection while keeping the speed/freq=MSS.

Rastering without rotation keep sucking. The mark made isn’t a circle with a flat bottom- it’s generally an inverted bell-curve crater, and a line is a plowed row with an inverted bell-curve cross-section. So with LI=MSS, the bottom isn’t smooth, it shows lines. And even if you have a lot of tiny layers in 3d slice mode, the lines always land in the same place (interlacing would fix this, but that feature doesn’t exist yet), so the “plowed field” effect still develops. It smoothed out if I went with like LI<(MSS/2), but then it’s slow and the heat is overlapping a lot with the last line.

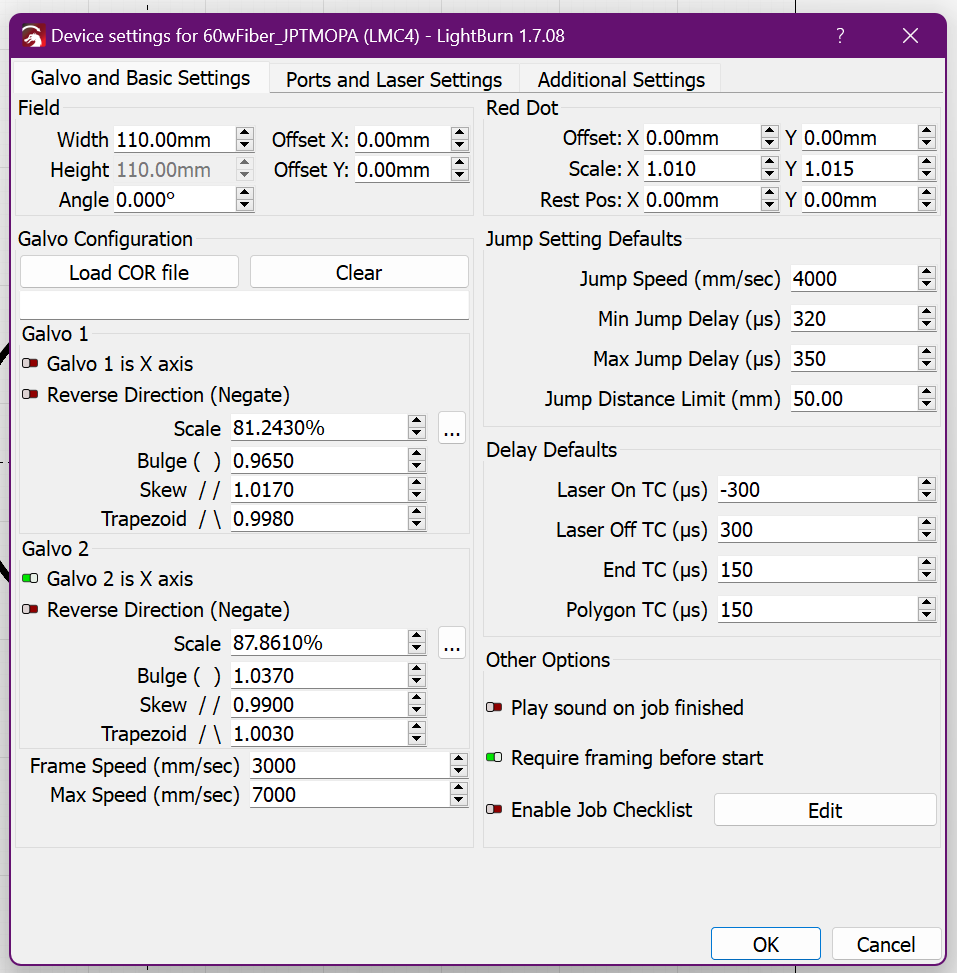

So I’m seeing rotation as essential, but you MUST have your TON/TOFF well calibrated to use rotation (or bidir). Those sync the laser fire command with mirror position. If TON/TOFF is poorly calibrated, it can still look good with no rotation/no bidir. But click “bidir” and the left and right-going lines don’t match up and it looks blurred horizontally. Rotation spreads the blur to the perpendicular axis, too.

I’ve made a lot of progress on HOW you’re supposed to calibrate TON/TOFF. All the info on how you’re supposed to do it, from every source, seems to be inaccurate and confusing and basically wrong for rastering. I developed a test that gave a super-accurate result, except I came to realize it didn’t give the same result with some changes in other params. Specifically the jump speed and jump delay are mattered- I’ve spent the day trying to understand exactly WHAT this jump is even doing, so I can figure out how it factors into calibration. It’s weird, the jump speed dramatically affects the time needed to raster, more so than would be explained by what I thought it did.

![]()