I finally got my omtech 60w (20x28 bed size) set up. I got it set up in lightburn and when I went to jog it to the center of the bed it didn’t even get close y axis wise. The controller says the x axis is centered which looks accurate but y is only like 1/4 down the total length of the bed. I went into the machine settings and saw the max travel distance was set by default to 700mx700m for x and y axis for some reason. I changed the y axis so it’d be accurate and it just made it travel less (obviously). The ruida controller says it’s at 350 x 250 but when I move it manually on the controller the y stops at 500 (which is the x axis max distance) about 1/4 of the way down. Any clues to fix this? If it makes a distance the rotary attachment cables were plugged in initially so I swapped those out. Any chance the x and y axis cables got swapped somehow? I’m so confused on how to resolve this

Make sure you turned rotary off…you probably left this checked to on. Then completely reboot the machine…as changes written to the controller sometimes don’t clear especially with rotary weirdness until you power cycle the laser

Figured out the steps were off by a lot. I had to calibrate them and fixed it quickly

Great, a big tip off is that it was incorrectly configured for the basic work area size. No telling what else isn’t correct.

Glad they tested this before shipping…

Whom did you purchase it from?

Fellow LEO. The steps were off by like 400% so I got that fixed relatively easy haha. Now getting the laser pointer to work is another problem

My laser pointer didn’t last over a month. Every time I really needed it, I had to adjust it. Started using templates and don’t miss the pointer. Currently the only thing tied to the head is the air line…

Just got a camera connection working and it appears to be very good at alignment.

I have seriously thought about the next tube having a factory aligned pointer as part of the manufactured tube. That’s the only real ‘accurate’ pointer that I’ve seen…

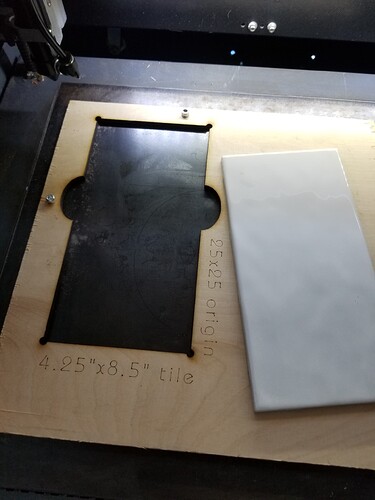

How do you frame accurately then? Only thing I could think of is making a jig of every job if the dimensions are different. Sounds like a pan in the butt to me ha

Generally when I purchase material, I know the size/shape of it. So it’s not an issue to make a ‘jig’ for it.

This is for 1 foot square mirrored tile…

I put wood chunks in there and can ‘guesstimate’ pretty closely.

I’ve installed a camera and I can now just put the part in there and copy the camera view to the background and place my artwork where needed without a worry about alignment…

Looks like I might need to buy a camera but I’m not sure how I’m going to wire it or where. I’ll be watching YouTube I guess

Here is one on print and cut, but you can use it for alignment in a similar way. Here he’s cutting a part larger than the work space.

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.