I bought a Omtech Chuck Rotary to my 60W red&black but I can´t made work. My laser had a DM545A controler, setting to 2000 Pulse/Rev and 1.91A. When I put less than 10,000.00 stepsper rotation in the rotary setting the rotary only shake but the 10k to up move 3.0-3.5 full laps. HELP ME it is the second rotary that I buy and apparently the first one was good and I have spent twice to find the same thing.

Slow down and I’ll try to lead you through it… OK?

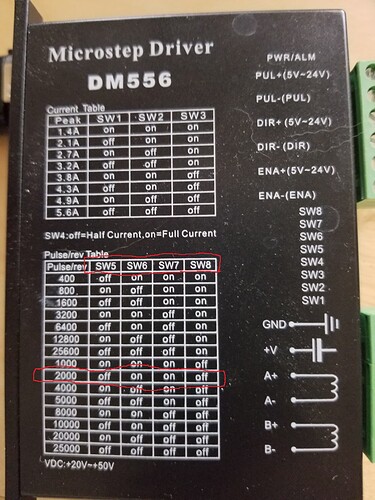

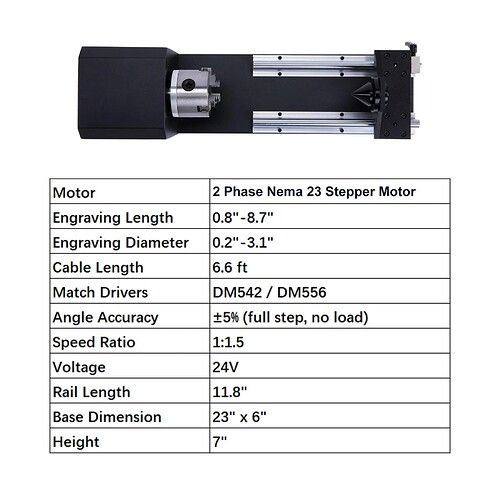

First you need to know the number of steps/rotation. Usually you read this from your DM545

This is one of mine… I have a PiBurn rotary for my ‘China Blue’ 50 watt…

I’ll use it, yours is similar. Sounds like you’ve looked at it anyway.

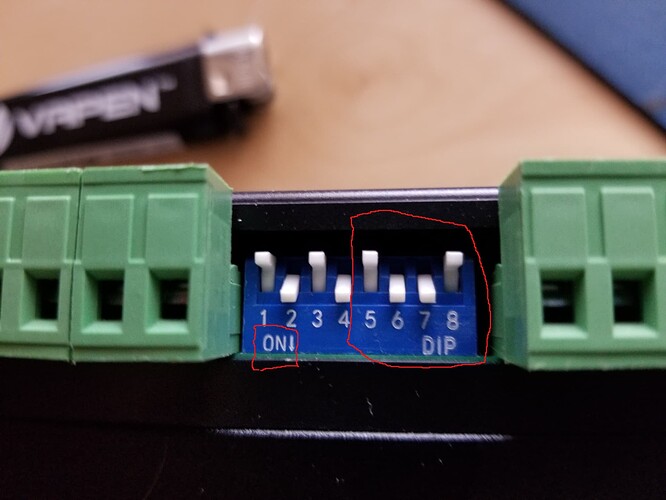

Check how the switches are set, notice the ‘ON’ direction, towards the circuit board (down). It’s marked on the switch body next to ON.

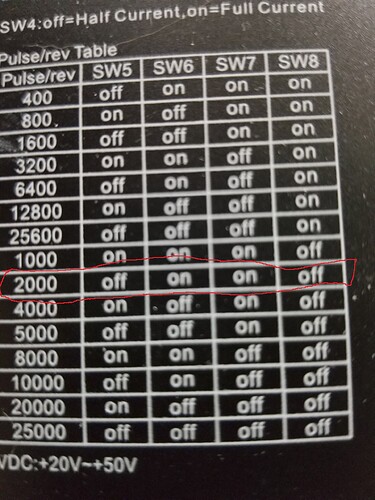

Match with the ‘placard’… 2000 pulses (steps)/rotation

This is fixed, so the software needs to know steps/rotation for the hardware.

If you enter the diameter/circumference of the ‘chuck’ and press ‘test’, the ‘chuck’ should make 1 rotation and back. A chuck rotary needs to know the diameter/circumference of the object to compute the ‘surface speed’. A ‘wheeled’ rotary this isn’t required, any size object will work without changes.

Make sense?

If this doesn’t work, you should ensure your rotary is compatible with the hardware…

More than likely it’s just the setup/configuration.

Good luck

![]()

I had the 2000 pulses too. but in steps per rotation what number must write?

2000 is the steps/rotation… same as pulses/rotation

![]()

don’t work!!! may be the rotary isn’t compatible with my driver controler

man what is the driver for a Y axis (left or right?)

[quote=“cristhian, post:6, topic:60678”]

man what is the driver for a Y axis (left or right?)

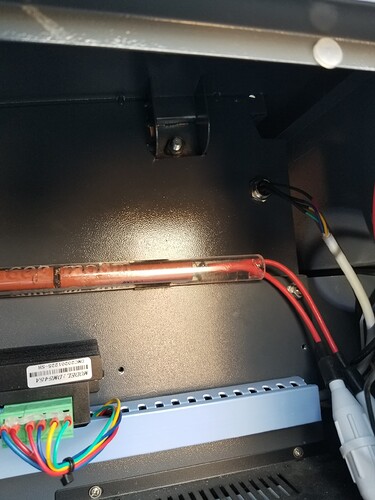

Mines on the right. Generally they put it as close as possible to the connector, but there really is no set way of doing this.

The Y axes is usually run to a connector in the cabinet for you to unplug the Y axis motor and plug in your rotary.

Here is mine, the one on the right goes to the plug in the upper right that I plug the Y or rotary into…

A little further away

Might have to take the cover off the wiring trough but you can follow it… or unplug it and check it out with an ohm meter.

Don’t get in a hurry, we’ll figure it out. You will break something if you get in a rush.

It seemed to work at some point, at least you got it to turn, so I think it’s how it’s configured.

Post a screenshot of the ‘Tools → Rotary setup’ if possible, I’d like to see it.

Take care

![]()

I think I found the problem: Omtech says that the correct controller cards are the DM542 and the DM556 and my laser has both DM545As, each DM556 card is $23 I’m going to buy both and change them and see if that fixes my problem trouble. What I don’t know is if the 545 is of lower quality than the 556

Hope you don’t break the other axis… Seems funny… However

Let us know how you make out…

![]()

my big question is: can I change only one driver or need change the two???’

That’s what I’d ask OMTech. More specifically…

If you change the driver on the Y axis to support the new rotary motor, is that ‘new’ driver ok for the original Y motor?

I assume you don’t want to change out the original Y motor out so it all works…

I don’t know… I’m not really that up on the difference of these motor drivers.

Suggest an email/phone to OMTech

![]()

yeahh that its my question!!! but seeing the quality of the original components of my laser without a doubt these drivers must be of lower quality than the ones I am going to buy, now the motor if I don’t know what will happen to it because it currently works very well. The safest thing is that I will have to figure out a way to put the other controller in the space to be exchanging if I need to use the rotary

Can you take a picture of your pins in the driver Y axis to see your configuration please

I don’t understand what you wish…

The wiring is printed on the motor driver. If you get the fields swapped it will go backwards…

![]()

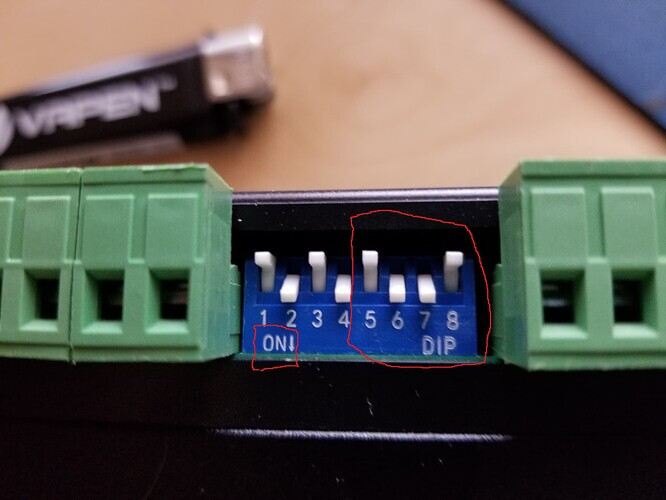

This picture is of the your Y axis???

I want to know te right pins position to work with the rotary with te DM556

Yes, that’s my machine and it’s set up for the rotary.

It’s set for 0110, on is down. or Off, On, On, Off

You should read it off you motor driver, it’s possible it has changed… I doubt it, but it’s better practice than following something blindly…

![]()

If the change of the driver fix the problem I’ll have two rotarys hahahahaha I bough 3 years ago one roller ratary that I never can do it work. (I use it to stop the door when the wind is strong)

I’ve never tried to configure for two rotaries… Great idea…

That would be great. I had to decide if I wanted a chuck or roller type and I do more cups/mugs than most other ‘round’ object. I can see the advantage of a chuck type for certain materials. Be nice to have both working like you will ![]()

I did do some 3/4" acrylic tubing on the PiBurn. You can see it in the photos and can kind of make out the engraving. That’s for my lps HV meter… ![]()

![]()

“&$”$# chinesse!!! my laser is wired wrong!!! one of two things either I adapt the rotor wiring to be used in my bad wiring or I go to the trouble of fixing the axis and my laser and wire it right. Chinese quality control deserve hard labor