I have a Creality falcon 10 w laser engraver. I have been using these goggles to watch it for a while now. However, in my research I have read that the Chinese goggles are not sufficient. Is it possible I have damaged my vision watching my laser using these cheap goggles? It is a diode laser.

With a visible frequency laser, good protection would mean no laser light would be visible to the user.

It will block that frequency. So you can’t perceive it either.

Don’t confuse the laser beam with the light generated during a engraving/cut where that light is created from the reaction of the materials to the heat. The CO2 generates lots of uv, according to science, so I avoid looking at the actual spot.

You didn’t mention your lasers frequency. I assume in the visible light range.

You buy something from China, you pay your money and take your chances. Generally there is little to no recourse if you do get injured.

I have a fiber laser, and the same frequency JPT source is used in a laser cleaner… in the videos of them using it, they are never wearing goggles…

On a positive note, I have Chinese goggles for all of my machines, except the co2… I wear regular glasses, so it isn’t a problem.

If you can cut the safety goggles lens with the laser, it will probably make ok safety glasses as it’s blocking the beam. I know this is kind of extreame.

You can purchase very expensive glasses from EU/AU/US if it makes you feel better… if they were as bad as the rumors we’d all be blind IMHO…

Good luck

![]()

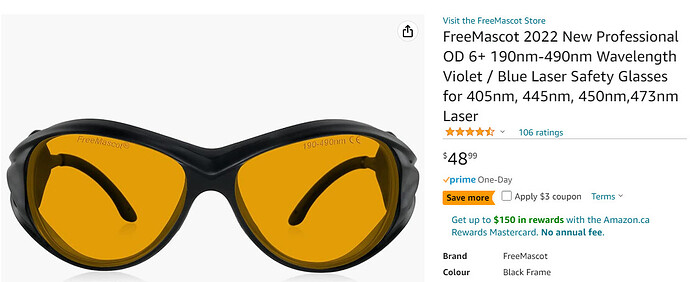

It does say that they are OD 6+ and that is what you need. The led laser should be around 450nm ± 5nm. I’m just wondering if they put that on there??? I have OD 6+ glasses that I bought on Amazon and the lens on them are an orange color.

These are the glasses I purchased.

It was a good answer from @jkwilborn but I can understand your being wary. You should be careful wherever you have sourced your goggles from. You only have one pair of eyes and there are ways in which you can help to improve your confidence in the product you have bought.

Genuine safety goggles, depending on your jurisdiction, should be instantly identifiable. One lens should bear text which describes the nanometer range of the laser light they should be used with (180 ~ 532nm) and the optical density of the lens (OD = 6+) and you may or may not see a percentage denoting the visible light transmission (48%VLT). All of the example values in parentheses given above are the values inscribed on one of your lenses.

Can the values be trusted is the first question that you must ask yourself. This will largely depend on the price you paid and where you obtained the safety goggles. Blindly trusting to luck and keeping your fingers crossed if they are of unknown Chinese manufacturer is not a strategy which could be safely recommended. Creality are a Shenzen manufacturer that has a well-known name so you have that going in your favour.

The laser you have is reputedly a 10W laser that outputs near to the 10W claimed. It is a diode laser that operates on or very near to 455 nm. If the goggles were supplied with the laser, then the colour of the lens would be expected to match the colour of the safety shroud that came with your machine. The minimum optical density required for your laser is an OD value of 4.00. (measured with the optical density calculator at the Laser Institute of America web page) and your goggles are marked 6.00+ so that places you above the density required for the wavelength and power of your machine.

Laser Safety Evaluator | The Evaluator | A Product of LIA.

As an aside, I once had a Chinese machine which included laser among its functions. The supplied goggles were too light for the power of the laser. I learned my lesson and I approached an industrial supplier of laser safety goggles. We went through the actual output and the wavelength as well as the usage and the maximum permitted exposure. I ended up paying ten times the cost of laser safety goggles found on places like Amazon and had bought a product that I knew had been calculated and supplied according to my use case.

A lot of information is required to safely fit laser safety glasses for the tasks envisaged. This page gives you some insight.

https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=762

If you want to ensure that your precious eyes are kept safe during use of your laser, I would suggest a pair of safety glasses supplied by an expert.

Unfortunately, money dictates most of our actions in all parts of life. I don’t know many of us that would have a laser of some type without them coming from China at rock bottom prices.

Imagine the cost of an iPhone if it had to made in the US… none of us would have one…

We love rock bottom prices… and it sometimes costs us dearly.

![]()

Thank you everyone. These goggles were purchased on Amazon link: https://www.amazon.com/Glasses-180nm-532nm-Wavelength-Protective-Removing/dp/B0BJKFKLPC/ref=pd_aw_ci_mcx_mh_mcx_views_1?pd_rd_w=FzAcj&content-id=amzn1.sym.07081e2a-c82a-4414-ba67-d1ea4791ec44&pf_rd_p=07081e2a-c82a-4414-ba67-d1ea4791ec44&pf_rd_r=E6MA9FCCCKBK9C305ZPF&pd_rd_wg=PeL4Y&pd_rd_r=a6c5191d-118c-4b34-b31e-c039ca44cb16&pd_rd_i=B0BJKFKLPC

I guess I just wanted to make sure that the value listed on them made sense. I use them in combination with an enclosure. For clarity I’m quite an anxious person so I like doing my homework along with seeing what people have to say about them. Thank you for your input. They were not included with my laser (Creality Falcon 10w) because everyone says the goggles that are included are junk typically so I was trying to do my due diligence. I think I might end up opting for a more expensive pair with better certifications. Has anyone ever forgot their goggles and looked at the light that flashes off the engraver? I haven’t done that but I’ve heard of people doing that and I wonder how dangerous that light flash might be. For clarity I understand you cannot look directly at the laser. And I also know the laser can bounce off, which is why it’s a good idea to use an enclosure and safety glasses. Does anyone use this particular pair out there?

I think you meant to say if you can not cut through…

Those are certainly look better than the unlabeled green goggles sometimes included with blue-light lasers.

If you assume the transmission data printed on the lenses correspond to the actual performance, then you’re good to go.

The problem: there is no way tor we ordinary folks to measure the optical performance of any goggles, because it’s a function of wavelength, power, and focus.

You probably saw this previous discussion, pointing out some things to consider and various sources:

If the lens passes the laser light, then it won’t absorb enough to protect your eyes and, most likely, won’t heat up enough to “cut”.

Consider polycarbonate: it’s transparent to visible light, so you can’t cut it with a diode laser, but it’s opaque to the 10.6 µm IR from CO₂ lasers and cuts easily (with poor cut quality, but that’s a different matter). Therefore, polycarb goggles suitable for CO₂ lasers are worthless for diodes lasers.

So if you can destroy your pricey goggles, they would have done a pretty good job of protecting your eyes. ![]()

Reiterated @ednisley response…

![]()

No, not quite, Lexan absorbs CO2 laser energy which is what makes it hard to cut and is also why it makes a decent shield. If the laser cuts easily through a material it is because the material does not absorb the laser energy. Bottom line, if the laser easily cuts through the material, it is not a good shield. If it cuts through, it gets right to your eye.

If the laser doesn’t cut/damage the material, or in other words absorb the energy in the beam, it couldn’t cut/damage the material.

If it doesn’t absorb the beam where does the energy from the lasers beam end up, in your eyes?

It must absorb the beams energy or it won’t cut/damage it, this is the basics of using a laser.

![]()

I don’t know how to further explain this to you so I will stop, but the original comment was if the laser can cut through it, it makes a good shield. This statement is 1000% wrong. Lets just go back to the though of, if you put something in front of your eye and the laser cuts through it, it will burn your eye, simple.

You entirely missed the point.

If you know or don’t know who Russ Sadler is, please watch his video on laser safety… at least the beginning. Maybe it will clarify what we are saying… I think we have a communications issue.

![]()

I’ve seen that video, the notion that materials are heated by the laser is not at issue here. The comment made that if a laser can cut through it means that it offers good protection is the issue. The examples give are clear enough. If the laser cut through it, it got to your eye.

But in any case I agree, we are talking side ways to each other.

No goggles are designed for you to stare into the laser beam…

That’s why I couldn’t understand what you were talking about.

![]()

And before it cut through?

If it cut through, there is nothing there.

Before it cut through?

Yes, I think the disconnect is around “absorbtion” and how it is applied. Lexan readily absorbs IR energy from a CO2 laser and takes longer to cut through, which is why it offers some protection. Acrylic easily cuts through and makes it poor for protection.

My main concern here was saying that if a material cuts it offers protection, that is not true.

As far as how much protection… When I first built my laser, I tested various materials in a materials analysis lab I have access to. Acrylic was terrible, Lexan was pretty good.

When I did a practical test, my 80W laser at 40% took about a second to burn through 1/16 Lexan, and several seconds for 1/4" Lexan which is what I use for my Laser on areas that are exposed.

For grins, I also sacrificed a pair of purpose made CO2 safety goggles and they held up about as good as the 1/16" Lexan, so you would still be at risk with a direct beam hit, probably fine for a scattered beam.

My issue is still the comment that if a laser can cut through it, it offers protection. Your comment eluding to how long it takes is really the key here.

Yes, of course that is the reality for us mere mortals. However, where personal safety is an issue, my MO is not to cheap out. My car tyres are Michelin because tyres are all you have between you and the scenery. My laser safety goggles ran out at $167.00 because my eyes are worth the expense of goggles that do what they must.

As for the expense of iPhones… I would be delighted to have a phone that only makes and receives phone calls. I do not need all of the other stuff that you get with an iPhone. I am sure that workers in China are making the iPhone far cheaper than the retail price in the countries to which the iPhone is exported would indicate.

As would I. Tell that to phone zombies that can not put them down.

Both are opaque to CO2 ir emissions. One will not absorb more than the other. The difference in reaction is at the molecular level and is the resultant heating effect. Acrylic goggles will work as well as my street glasses (polycarbonate).

I buy regular safety glasses made from polycarbonate from Home Depot so people who visit can watch the machine run.

Most people and information on the Internet claim that polycarbonate it more difficult to get good edges and cuts… I have also found that to be true, so I only use it when, when the price is right as in, it’s given to me.

Surprising you have different results.

I only have a 40W laser…

![]()