$.50 for the wad of metal left after using the baseball bat on an Ebay CNC. The machine is a generic 2418 with a 5.5w laser with a Cronos Maker grbl 1.1f board. Running evaluation copy of LB on a Win7 computer. Assembly went OK but the laser seems to only produce enough power to barely scorch wood and that’s at 300mm/min speed. Many attempts to change settings have proved futile. Read and read all that I can find so far but it hasn’t lead to a solution. If anyone can advise, I’d be most appreciative. Thanks for reading.

$0=10

$1=25

$2=0

$3=0

$4=0

$5=0

$6=0

$10=1

$11=1.000

$12=0.002

$13=0

$20=0

$21=1

$22=1

$23=7

$24=25.000

$25=500.000

$26=250

$27=2.000

$30=1000

$31=0

$32=1

$100=800.000

$101=800.000

$102=800.000

$110=500.000

$111=500.000

$112=100.000

$120=45.000

$121=45.000

$122=45.000

$130=240.000

$131=180.000

$132=40.000

Are you positive that the speeds are set to mm/min? (worth checking that first, as mm/sec is the default)

Thank you for the reply. Assume speeds are $110, $111, and $112. When I open grbl settings in Laser grbl, the setting menu says those three are in mm/min and reports 500, 500, 100 respectfully. Can the setting menu in Laser grbl be wrong?

Frank

No, they’re correct - this is them in your settings:

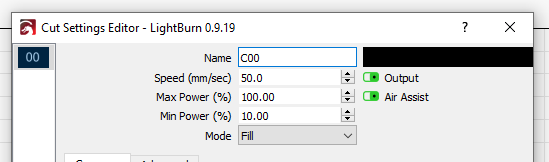

What I meant was, in LightBurn itself, what speed have you requested when running a job? LightBurn’s default unit of measure for speed is mm/sec, not mm/min:

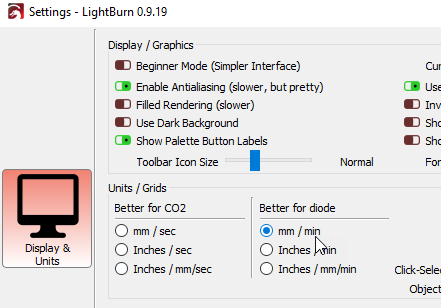

But you can change that in the settings:

LB was set to mm/min

I’ve noticed the laser doesn’t respond a direct ON command from the console…as in M3 S1000, but the FIRE button does work OK for a low power beam

M3 enables the laser, but only when in G1 mode. By default, the system is in G0 mode (travel moves), and the beam is disabled for those.

You can turn on the ‘Show all’ toggle in the console window to see all the GCode LightBurn emits.

Here’s what I think I may have discovered. I can get a stationary full power beam (think it’s full) w/ Laser grbl, but when I run a simple box outline at 300mm/min and 100% power – nothing…the beam is on, but not enough to burn anything, even at 2-3 passes. There “seems” to be something about movement that robs the laser of power. Does this sound reasonable and if so, how to fix? I see where there is a grbl 1.1h firmware available. Any familiarity with that version? I’ve got 1.1f

Would rather buy and use Light Burn if possible…vastly superior features

1.1f is fine - it’s what most of our users have. Draw a box, set it to 300 mm/min, click ‘Save GCode’, save it as ‘box.txt’ or something, and attach that file here.

Box attachedbox.txt (295 Bytes)

The GCode verifies everything you’ve said about your speed and power settings, so you’re not doing anything incorrect. You might have a bad laser module or controller, or you might not have a strong enough power supply to feed the steppers and the laser…?

I’m grasping at straws here - Nothing incorrect in your settings or GCode that I can see, so you should be getting a decent burn.

Thank you for your attention in this. My Ebay/Amazon research shows many replacement 5.5w lasers coming with a power module/chip with it’s own power input…2 - 2 wire cables from the module to the laser, a 3 wire out to the main board, and a power input. My setup came with a single main board with a 3 pin plug marked “laser TTL” and the laser had a 3 wire cable, making only one place to plug the laser into. There is a 3 pin jumper marked “spindle” and “laser” depending on selection. My power supply is a 24v 5A brick. I assume the board steps the voltage down to 12v for the laser. Wondering if 5A is enough for motors and laser off of one board?

I may have struck gold in Russia. Had a Russian user respond on the Laser grbl FB page and he gave me settings below. Seemed to work like a CHAMP!!! Do the changes he recommended make sense?

2 weeks of head banging and it came to an end in a couple of minutes. He advised that if the motors warmed, to reduce current on the drivers…but that’s in the future

$ 0 = 15

$1=255

$2=0

$3=0

$4=0

$5=0

$6=0

$10=1

$11=1.000

$12=0.002

$13=0

$20=0

$21=1

$22=1

$23=7

$24=25.000

$25=500.000

$26=250

$27=2.000

$30=1000

$31=0

$32=1

$100=800.000

$101=800.000

$102=800.000

$110=2000.000

$111=2000.000

$112=1100.000

$120=800.000

$121=800.000

$122=800.000

$130=240.000

$131=180.000

$132=40.000

Those changes keep the steppers locked, increase your maximum speed, and increase your acceleration. As long as the motors don’t skip when using these, they should be ok. Your steps per mm settings are high enough that you will not be able to go faster than 2200mm/min without seizing up the controller, so I wouldn’t increase $110 / $111 any higher.

Status report: Motors and LB seem to work very well together, but I’ll be darned if I can get anything approaching full power from the laser. Internet surfing has shown me there are people getting results with lasers half the power of mine. My main interest was etching tile with the 5.5w I ordered and this guy is burning this quality with a 2.5w

I must have a defective laser or there is a compatibility issue with the board. Thank you for the attention in resolving this problem.

Don’t attempt to use a speed higher than 2000 mm/minute (33.3 mm/sec) or the laser will automatically reduce the power because it can’t go that fast, and it’s trying to give you the amount of burn you asked for. What speed did you try?

Tried from 200 to 1500 at 40% to 100%. Got a decent wood burn at 700 & 60% which seems like a lot for wood out of a 5.5W. Got a 5.5w replacement attempt on order. It has a separate power supply and board and hopefully plugs into the PWM out on the main board. Impressive tile burns, don’t you think? All from a home built 2.5W @ 95%

Hi FrankF I have a chart for the grbl settings. Good reference to print.!

| $-Code | Setting | Units | Setting Description |

|---|---|---|---|

| 0 | Step pulse time | microseconds | Sets time length per step. Minimum 3usec. |

| 1 | Step idle delay | milliseconds | Sets a short hold delay when stopping to let dynamics settle before disabling steppers. Value 255 keeps motors enabled with no delay. |

| 2 | Step pulse invert | mask | Inverts the step signal. Set axis bit to invert (00000ZYX). |

| 3 | Step direction invert | mask | Inverts the direction signal. Set axis bit to invert (00000ZYX). |

| 4 | Invert step enable pin | boolean | Inverts the stepper driver enable pin signal. |

| 5 | Invert limit pins | boolean | Inverts the all of the limit input pins. |

| 6 | Invert probe pin | boolean | Inverts the probe input pin signal. |

| 10 | Status report options | mask | Alters data included in status reports. |

| 11 | Junction deviation | millimeters | Sets how fast Grbl travels through consecutive motions. Lower value slows it down. |

| 12 | Arc tolerance | millimeters | Sets the G2 and G3 arc tracing accuracy based on radial error. Beware: A very small value may effect performance. |

| 13 | Report in inches | boolean | Enables inch units when returning any position and rate value that is not a settings value. |

| 20 | Soft limits enable | boolean | Enables soft limits checks within machine travel and sets alarm when exceeded. Requires homing. |

| 21 | Hard limits enable | boolean | Enables hard limits. Immediately halts motion and throws an alarm when switch is triggered. |

| 22 | Homing cycle enable | boolean | Enables homing cycle. Requires limit switches on all axes. |

| 23 | Homing direction invert | mask | Homing searches for a switch in the positive direction. Set axis bit (00000ZYX) to search in negative direction. |

| 24 | Homing locate feed rate | mm/min | Feed rate to slowly engage limit switch to determine its location accurately. |

| 25 | Homing search seek rate | mm/min | Seek rate to quickly find the limit switch before the slower locating phase. |

| 26 | Homing switch debounce delay | milliseconds | Sets a short delay between phases of homing cycle to let a switch debounce. |

| 27 | Homing switch pull-off distance | millimeters | Retract distance after triggering switch to disengage it. Homing will fail if switch isn’t cleared. |

| 30 | Maximum spindle speed | RPM | Maximum spindle speed. Sets PWM to 100% duty cycle. |

| 31 | Minimum spindle speed | RPM | Minimum spindle speed. Sets PWM to 0.4% or lowest duty cycle. |

| 32 | Laser-mode enable | boolean | Enables laser mode. Consecutive G1/2/3 commands will not halt when spindle speed is changed. |

| 100 | X-axis travel resolution | step/mm | X-axis travel resolution in steps per millimeter. |

| 101 | Y-axis travel resolution | step/mm | Y-axis travel resolution in steps per millimeter. |

| 102 | Z-axis travel resolution | step/mm | Z-axis travel resolution in steps per millimeter. |

| 110 | X-axis maximum rate | mm/min | X-axis maximum rate. Used as G0 rapid rate. |

| 111 | Y-axis maximum rate | mm/min | Y-axis maximum rate. Used as G0 rapid rate. |

| 112 | Z-axis maximum rate | mm/min | Z-axis maximum rate. Used as G0 rapid rate. |

| 120 | X-axis acceleration | mm/sec^2 | X-axis acceleration. Used for motion planning to not exceed motor torque and lose steps. |

| 121 | Y-axis acceleration | mm/sec^2 | Y-axis acceleration. Used for motion planning to not exceed motor torque and lose steps. |

| 122 | Z-axis acceleration | mm/sec^2 | Z-axis acceleration. Used for motion planning to not exceed motor torque and lose steps. |

| 130 | X-axis maximum travel | millimeters | Maximum X-axis travel distance from homing switch. Determines valid machine space for soft-limits and homing search distances. |

| 131 | Y-axis maximum travel | millimeters | Maximum Y-axis travel distance from homing switch. Determines valid machine space for soft-limits and homing search distances. |

| 132 | Z-axis maximum travel | millimeters | Maximum Z-axis travel distance from homing switch. Determines valid machine space for soft-limits and homing search distances. |

Thank you, Roko and Mr. Wizard. Here’s where I’m at today. Got rid of the previous laser/cnc (bad laser or board) and got a 3018 w/ 5.5w laser and a mystery enfolded. The new board doesn’t report what firmware ver. it’s running and several of the previous line number features are missing including $30 & $31. Because LB doesn’t detect them, there doesn’t seem a way to set a reliable power level. To deepen the mystery, the former Chinese Ebay tech person wrote in a email, that max power was 2000 as set in Laser grbl even though the $30 & $31 values were 255 and 0…also tried 1000 and 0. When using a 0-2000 scale in Laser grbl, it seems to control the power level well, even though I have no idea where the range is set.

I’d rather use LB to work with because of it’s extensive features. Anyone reading this that can shed some insight would be most welcome. I’ve posted the $$ grbl dump that’s on the board.3018grbl12-1-20.txt (1008 Bytes)