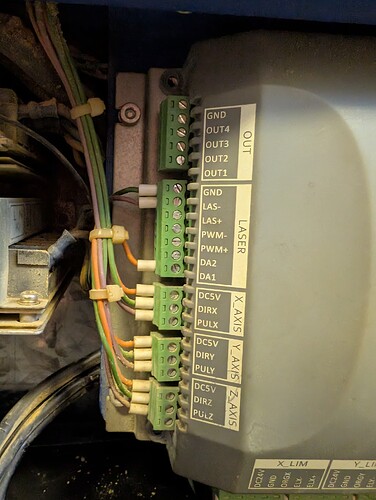

We have an old CTR TMX65 using a Leetro MPC6565 control board which we use to cut models out of 2mm and 3mm MDF.

Our cut settings have remained the same for some six years; we use 80% power for a through cut and just 6% power for a light surface etch for some surface details.

A while ago we noticed the surface detail wasn’t clear. To achieve the same sort of clarity, we had to increase the laser power from 6% to 24%.

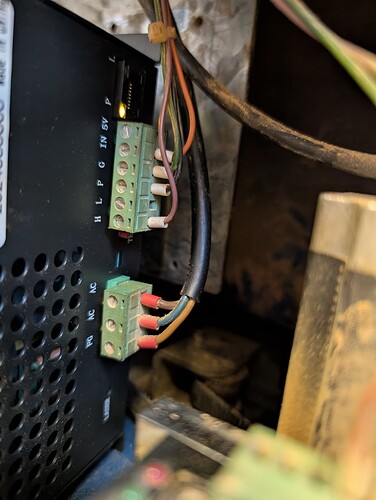

Thinking that this might be the laser signalling the end of it’s life, we ordered a replacement. The replacement showed the same problem, so we thought it might be the power pack. This also showed the same problem - 24% power required for a very superficial surface line.

We’ve now tried four power packs and three laser tubes (the original plus two replacements), one of which the supplier did test and was honest enough to say there were some irregularities - but even a second replacement still shows the problem.

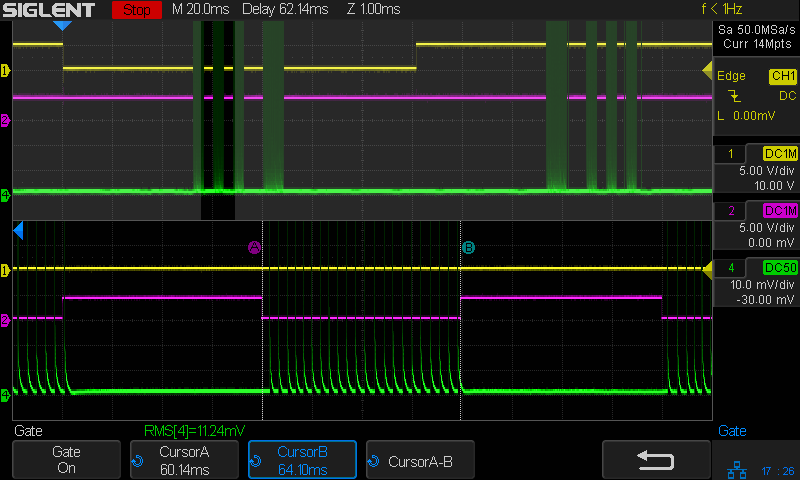

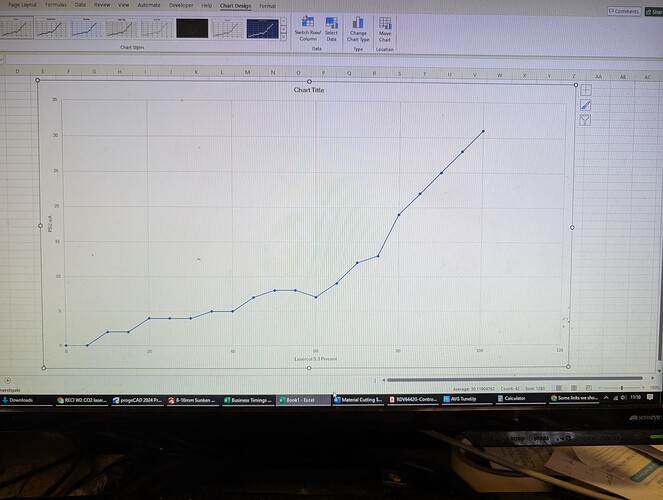

I’ve noticed something during trying to fix this problem. There’s an LCD panel on the power pack that shows the power output when the laser fires. It comes set to about 12mA but is rated up to 30mA maximum. We can set the output current with a screw on the power pack, and we set it to 24. However, when we set the power output (from software) to 6% - nothing registers on the laser. 6% of 24 is about 1.5 so it really SHOULD be registering. We then looked at some higher power settings in software and none of the “percentages” matched the current drawn shown on the power pack - the power pack always read lower than expected.

So, long preamble, but we were wondering two things;

-

is the relationship between 0-100% power in software and the current drawn on the power pack linear? ie if we have the pack set to 24mA maximum, should 25% show 6mA, 50% show 12mA, etc?

-

If the answer to the above is “yes”, are there any other components that might have failed that could be causing us this problem? Something on the board perhaps?

Hope someone can help, this has been driving us nuts for weeks!