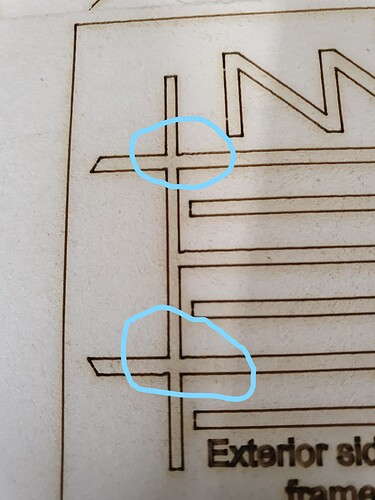

If I import a DXF file to Lightburn and send it to the machine immediately without moving any parts or adding tabs the cut is perfect. If however, I move any part or apply tabs, the file becomes corrupt in some way and results in a wiggly cut at random location across the work. Please let me know if you require any files sending.

It’d be a good idea to post the dxf and also a picture of the resulting engraving.

Here is the DXF file and a picture of the cut along with the faulty .lbrn file. The laser manufacturers have been working on this all morning and finally proved issue to Lightburn after they sent the same file using RD Works.

P2L.dxf (17.1 KB)

SGS-L1.lbrn (166.5 KB)

Material is 220g card

It looks like you might want to adjust the setting that controls the speed at which the laser goes into or out of corners to something lower.

Already been done. Every parameter has been tested/adjusted. When file is sent immediately after import, there are no errors, move one of the parts a few mm and the error appears.

You’re talking about moving the part in Lightburn, and re-sending it?

Yes. Moving the part within the Lightburn work area.

Very strange. Could be a LB bug.

When you’re moving it in LB, does the end effect move the cut placement on your laser? Like if you’re moving it left 1" in Lightburn, are you doing that to move the piece over 1" left on your laser?

Yes, the pieces move in respect of their position in LB and it is reflected in the position on the laser. The parts need to be moved to minimise material wastage.

I looked at the DXF file. Is that the case, that there are only single lines? I work with my own CAD (written by myself 30 years ago) and always create POLYLINEs and have never had a problem with it. Can you try to combine the individual lines into polylines?

This would ensure that the contours form a single entity; in any case, this prevents changes in the process and different calorific values.

I converted your drawing to polylines, here is the result.

P2L-Polyline.dxf (8.2 KB)

This is really interesting.

Are you willing to post the RDworks file as well?

I’d like to get this into testing so we can see what you’re seeing.

Here is the RD Works file, sorry for the delay.

SGS-L1.txt (287.2 KB)

Do you have any update on progress please?

I don’t appear to be getting a response, is this the correct place to post issues?

Honestly email is better if you’re expecting a direct response from LightBurn. The forum is monitored, but not “direct”.

Your layer setting for “Cut light card” has a 0.09mm outward kerf applied, meaning that all the corners are slightly rounded, and the laser will likely take the corners slightly faster as a result. Is this intended? Do you have the same kerf offset applied in RDWorks?

Hi Oz

Thanks for getting back to me. No, the kerf is not intended and I’m not sure how it got there, no doubt crept in by mistake and no, there is no offset in RDWorks. I will make some test cuts and advise.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.