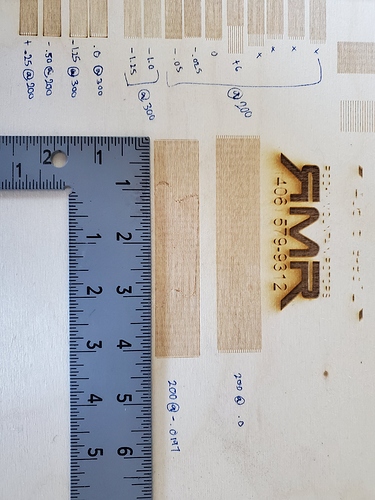

From the top lol power supply died i replaced and went to go engrave some leather and got terrible results. At that point I had changed nothing other then the power supply. I did a little home work and figured out the offset was some how off so I started playing with those. Prior to the power supply going bad I never messed with the offset at all and never had any issues. I think the offset is only part of the problem because I’m still not getting a lot of fill in places. This is once again a consistent problem making me think its a settings issue not a hardware issue but I dont have a hole lot of experience with lasers or computers for that matter so I could be very wrong on the matter. I love the software and the machine has been great up to this point. I just don’t know what else to try and change at this point to even go in the right direction.

I don’t know of it’s a scan offset problem or a hardware problem, but I think it’s related to the “missing” bits of your small text. Look at your phone number. In the wide places where the laser is on for a while, it’s mostly fine. In the narrow (mostly vertical) places where the laser is on only a brief time it’s very faint…

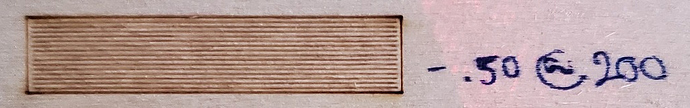

So look how short your scan is in your test. Those scan lines should reach all the way to the border.

It clearly misses out on some time at the beginning and end of each line. Now shorten those on times a bunch until the “missing” part becomes a big percentage of the total on time and it starts looking like your narrow bits of text.

I have to wonder about that new power supply. If it wasn’t too expensive and you need the machine badly it might be worth picking up another to try.

Have you looked at the overscanning setting in LB. I had similar problems when using low acceleration settings. Setting over scanning to ON at the default 2.5% made all the difference. Access via the layer control with type set to FILL.

Cheers

David

He has a Ruida controller. Overscanning is taken care of internally and not user adjustable.

To me this looks like the new power supply is bad. It’s firing late, or not at all for the short segments. I can’t say for certain that’s what this is, but you shouldn’t have gaps on either side of a properly aligned Fill + Line shape the way you do here:

I bought a 2.nd hand machine approx 6y old. (80-90W Reci tube) and experience same problem on short segments. Bought a new HV-PSU still same issue as old HV-PSU. My guess is the tube somehow has a “slower reaction” time. If i look at my engravings under magnification glass, it’s clear to see how the power increases (shallow to deep cut) over 0.5mm-ish. It cuts 6mm birch no problem, long segments no problems. The money is not for a new 90W Reci so fo now I live with it :-/ But following if you get a resolution…

So I was thinking maybe my stepper motor was not set up right and that was causing the short lines but I just checked all the measurements and its spot on. I also blew up the test and it seems to have better talorance idk.

Once again I want to thank everyone for helping and sharing your knowledge. Its not fixed but you guys at least give me a little hope I can get it fixed so thank you.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.