I’ve just replaced the 60w laser tube, in my 10 year old machine, the old tube must be five years old and has had plenty of use. The new tube had cables already fitted, but they were too short to reach the power supply, so fitted an additional red lead between the two with proper laser cable connectors. Running the laser it seems well down on power, my laser test meter is only showing 12w at the end of the tube, running at 70% power the amp meter is showing 10mA. I’m wondering if it’s the additional connector causing an issue or is my power supply on the way out?

Should be ok - what connector did you use?

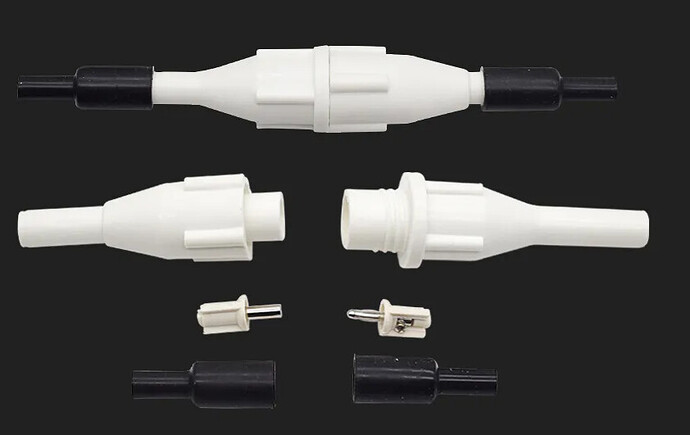

Like this?

I have joined the high voltage cables before and rather than use a connector I prefer to just directly twist the copper strands together and solder for good measure, then wrap with high voltage rubber splicing tape. I guess it depends on the quality of the connector you are using.

Also check for any sign (or sounds) of arcing on the high voltage line and make sure the black return wire from the cathode end is properly terminated back at the high voltage power supply, and that your ammeter connections are good.

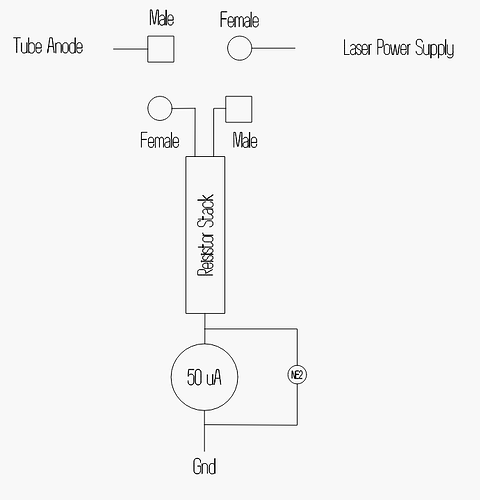

When I put a hv meter on the machine, I used these to connect the 800mOhm resistor to the supply.

I used opposite connectors so I can take the resistor out of circuit and still plug them back in.

You did use HV wire?

These are pretty simple, so if it’s lasing and producing 12W look at the TEM mode of the tube and ensure it’s compliant. It is possible to get bad tubes.

There isn’t much to check here, about the only thing you can check is the operational mode.

![]()

Thanks for the replies, yes my connectors are the same as in the picture and I am using HV cable. I did think about soldering one of the connections, so will give that a go.

The laser does fire, the light inside the tube looks good and there is no arching sound. I’m pretty sure my mirrors are aligned okay as I am getting a pulse burn below the laser head and it does make a nice clean line when I use the cut setting.

My tube is by MCWlaser and the power supply is from Cloudray, hopefully that isn’t the problem.

I would check the alignment again. Make sure there are no hot spots on the lens assembly. Double check that your beam is passing cleanly through the centre of the lens.

Try making a spot of the material, first at focal height, and then again a good few inches below focal height. to they hit one-atop the other?

Do another beam test out of focus, do you get a nice clean round burn or does it have some clipping.

Do you have an Amp meter in line with the cathode?

Thanks for the suggestion, I’ll check alignment again. The only amp meter is the one coming out of the power supply box which is connected by a network cable. Strange though that my laser test meter is only showing 12w coming out of the end of the tube.

I’d say it’s likely you have a failed tube. You do have new things that don’t work. I measure mine before m1 also. This eliminates any alignment issues you may have.

Did you turn the knob up on the unit connected to the network cable? This could limit your current.

If it’s really a 60W tube, 10mA is almost 1/2 way of the maximum, which is 22mA.

That should relate to almost 50% (OK 45%) power or a little over 25W.

So I still think you’re tube has gone south or arrived south. Did you do the m1 test for tube mode? If this is bad, then it will never align, have power or produce a good beam quality resulting in a larger inconsistent spot.

I’d suggest contact with your vendor and see what they advise.

![]()