quick intro:

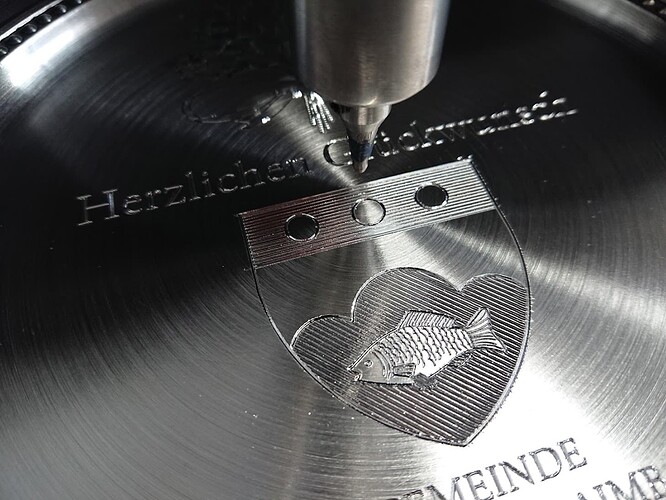

I took over 3 old ('90ish) Newing Hall engravers which i had kept running for a client over the last 20 years yet - so i knew that the original setup of software and controller would have to be replaced for any serious work and modern workflow to be done with it.

the machines are simple x/y-tables with a solenoid valve to pneumatically drive a tool into the workpiece - so simple on/off of the (not-)laser.

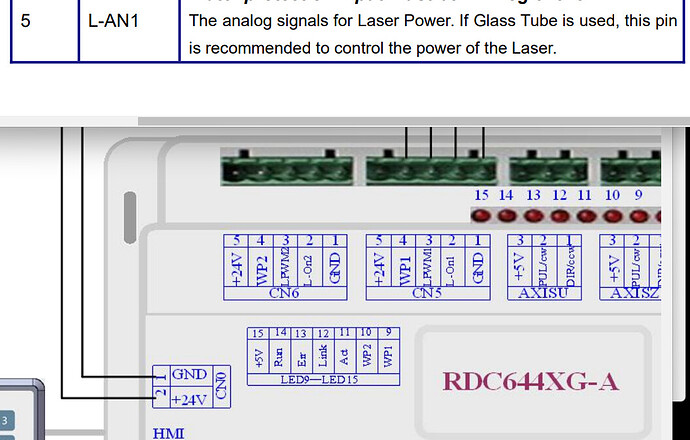

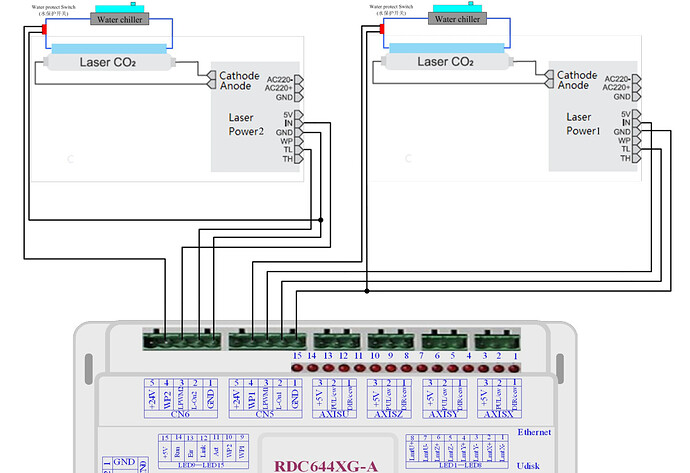

i’ve been tinkering with several approaches to retrofit these with some new controller (mach3, smoothieboard, linuxcnc) - but wasn’t quite fond of any of these till now - and that’s where i happened to discover Lightburn (right after buying a cheap Neje-Laser). Realizing it also supports controllers of ‘bigger’ machines and finding these being available separately and even include things like a control panel and could be controlled via network i ordered a Ruida 6445.

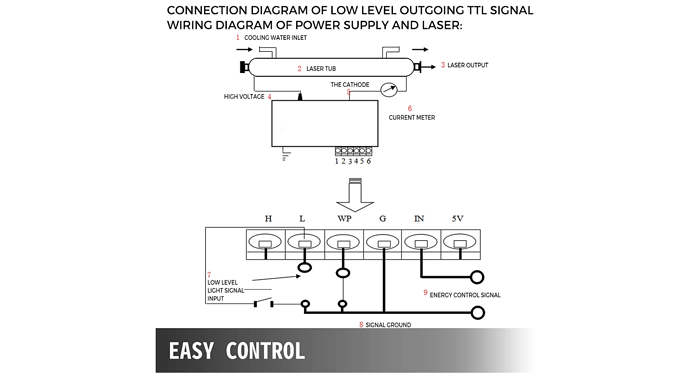

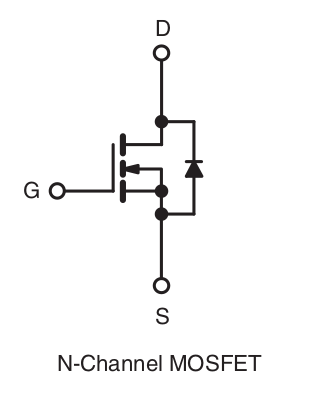

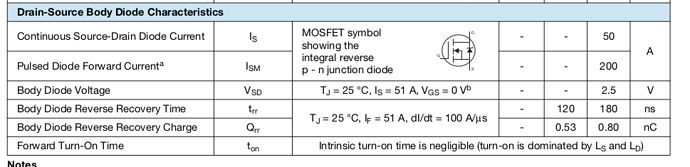

It was easy enough to get things moving, but now i’m at the point at which i’d need to control my (not-)laser. obviously it’s not PWM and i know of the danger of solenoids shooting voltage back to the controller - so i hope that someone round here can give my guiding hints on how to best approach this.

tia,

markus.