Ok Have had Rotary a fue day’s now. And Thanks for all the help by the way … Now when I turn on the laser with the Rotary on the Roatry will make about 1.5 turns on the belt but when it comes back the opposet way it lags bag so slow like 1 step at a time…and the motor is getting warm very warm i do not have anything other than a people themomeater or kitchen one but the longer I let it stay hooked up and the laser idle it gets hotter I dont want to try and just let it burn up… but I bet it would if I just left it … and the motor is getting a feed back I think not shure but I can put my calipers down bu it and the numbers gos crazy…I have only found 1 video on youtube and It’s got the same Rotary and it is Laser. Rotary UP Grade Set up Cheapest I Could Find . Youtube anyway the guy burns up a couple of motors come to find out the motors are 17steps and when he puts a 23 step motor trouble is gone I dont know if this is my problom or what with the motor turing back so slow any help ?

As I mentioned at the start of this, you can get incompatible motor/motor drivers. All you can do is look at the specification to ensure you’ve got a compatible pair.

When you power the machine up, it is configured to ‘home’, sounds like that’s what it’s doing.

I have worked on my machine and the motors have a ‘hold’ current, that is set by the motor controller. Mine get too hot to put my hand on them, other than a quick touch… But check the motor type and driver.

I guess I don’t know what problem you have at this point.

Don’t tell anyone, but I home the machine, then hot swap out the Y table for the rotary…

![]()

Im busy to day but soon as I can I’ll try this Thanks you will hear from me.

Thank you jk. It is working flawlessly with that setup!.. now i’m sending it back the rollers will not work thet scrach the SS tumblers I thinking about getting a chuck roatry But Thank you again.

Thank you jk I did get a chuck roatry and it works fine Again thanks for all the help

Well,

Looks like I will have to do the same and get a chuck style rotary…

This one (the replacement from the original that burned up) worked fine for about 5 tumblers.

Went to use it again and it ran a full cycle on a tumbler, stuck another in and it is not moving at all now. Assuming the motor is fried again… They come with a “QC Pass” sticker on top of them, every time it gets really hot to the point of that sticker becoming see-through the motor quits working.

There has either GOT to be too much power going to it or FoxAlien is giving me junk motors… Right?

I’m running into the same problem on both of my rotaries (one is a 4 wheel roller and the other is a lathe style). They both get so hot that I can’t leave my fingers on them for more then 10 seconds or so. I’m researching two different paths to dealing with this problem. After watching a video on the installation of a rotary, which required an additional driver be installed, the maker of the video cautioned that if the stepper motor was getting too hot you should step down to the next lower current setting. The NEMA 23’s on my OMTECH 50w are currently set to 3.31 amps peak and I’m considering setting them at 2.84 amps peak. The other possibility for reducing heat is changing SW4 on the stepper driver from full current on standby to half current (changing SW4 from on to off). Take these ideas with a grain of salt as I am just starting to look into ways of reducing what I think is excessive heat coming off these stepper motors. As you said, you are only able to do about half a dozen tumblers before your motor is cooked. I know that some heat is expected because of the constant current, but when you can’t touch it for more then a few seconds there’s something wrong. I hope you are able to resolve your issues and find out what’s going on.

Mine is also an OMTECH (100W).

Thinking of giving up on it - haven’t made a dime yet ![]()

Also have no idea how you can change the peak amps on the steppers but would love to know. I can’t imagine that little stepper needing that much power, but can not find any power specs for it and manufacturer won’t provide.

Also have no idea what SW4 is?? Hopefully you’re able to fix yours… I am about to give up on replacing these motors and say screw the rotary.

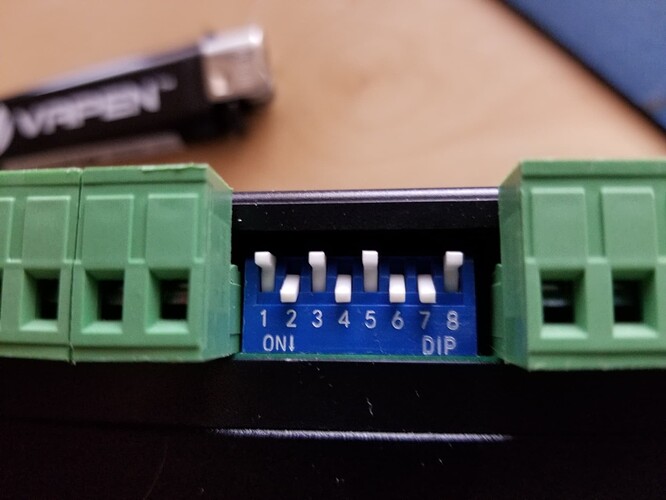

Check out the motor driver board and it will have a set of switches and a chart to guide you.

Switches between the connectors. On is usually towards the board. Should be marked.

Make sense?

![]()

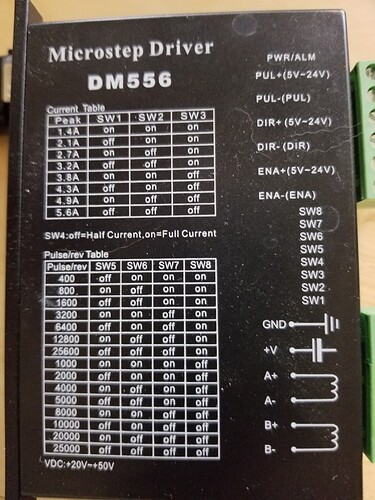

If you look back at the pictures that Jack Wilborn posted there is a blue dip switch on the stepper driver. Switches SW1 through SW3 set the current (in his picture it’s set at 4.3 amps) based on the chart in the picture right below it. Switch 4 (SW4) determines whether the motor gets full current on standby or half, and the final four switches set the pulses per rev (Jack’s is set for 2000). Of course, all of this depends on what kind of stepper drivers are installed in your laser. I have DM545A’s in my 50w, but it is set up exactly like Jack’s (except current, mine is at 3.31 amps). Like I said, I’m going to do my homework first before I make any changes to the current settings. I’m going to pose the question in the several OMTECH user groups I belong to and see what the experts have to say.

Jack, since your here, what is your opinion on full and half current on standby? The stepper motor is getting so hot that it’s warping the plastic frame on my rotary (it has a NEMA 23). I wouldn’t think a rotary would need full current on standby if it’s just sitting there. Any thoughts on the subject?

The current rating for a NEMA 23 is 2.8A. It’s upper temperature limit is 50C (122F).

I doubt you need full power to ‘hold’ any of the axes on these machines. I might just drop mine and see if I see any issues… Mine run pretty hot also.

If you notice the peak value on my ‘factory’ configuration is 4.3A. I’ve questioned this before.

I’d drop in the ‘hold’ current and see if that helps reduce the heat. If you’re still having heat issues, I’d lower ‘peak current’.

I don’t know the scope of what operations could be affected.

It makes sense that it would effect how quickly you can accelerate/brake and maybe upper end speeds. Increasing the overscan is also a probability. I would think it would involve more than just a switch.

The torque on these motors drops off quickly as they run faster, limiting the current will also reduce the available torque. The controller would have to know about the degradation of the torque.

It might simply be that they just design this stuff with such an ‘over kill’ range, they don’t need to worry about this kind of thing… ?

@bionicback321 sounds like we have the same kind of animal, my peak is much higher than yours…?

![]()

The DM545A drivers in my machine are set to 3.31 amps and full standby current. After going back and looking at the specs for the NEMA 23 I ordered it does say 2.8 just as you mentioned. Good call, thanks! I’m going to make the changes in current settings (Y axis only for now), do some testing and see how it goes.

Jack, I made the changes you suggested (half instead of full standby current and 2.8A instead of the 3.3A that was set at the factory), and my stepper motors are cool as cucumbers, well, lukewarm anyway. The rotaries are no longer getting too hot to touch and my MF1220-50 seems to be operating just fine in normally X,Y mode as well. Time will tell. I can’t tell you how much I appreciate your help and advise, you are truly the indispensable man ![]() .

.

That’s cool… glad you got some kind of solution. Glad to help if possible.

If you find any glitches, caused by the reduction in current let us know…

Take care

![]()

Will do Jack, I hope the OP can benefit from this as well. I really didn’t mean to hijack his post ![]() .

.

No worries on the hijacking @bionicback321 - thank you all! I am glad I’m not the only one with this issue and the more the merrier - helps to have you guys around since I’m not as available as I’d like to be!

THANK You!!! This may be the problem, although it does seem odd that when my normal X/Y axes motors (also NEMA23’s) are hooked up, they do not get anywhere near as hot as this one.

Lol… Mine is getting hotter than that - I can not touch it at all without getting a burn blister. Dripped a drop of water on top of it and it Bounced off!

@jkwilborn regarding the hot-swapping, I have been curious about doing this - it’s in my blood to do such things i.e. hot-swapping light switches / outlets, but the laser industry is new to me and found it intimidating until now ![]()

The standby current does seem to be the issue - I tend to leave the laser on when I’m in between projects or my son distracts me, and it seems if it’s 10 min or more on standby is when the motor overheats.

![]()

If these motors are serviceable, and anyone wants a few of them - let me know. I don’t have the time for them, was going to throw them out but was hoping they might be able to run again (all 3 of them have only ran 1 tumbler).

also still have the original NEMA17 powered “Genmitsu” brand rotary that is of zero use to me… never even got that one to run.

Also does anyone know of a good place to look to sub out some engraving work?

Tumbler orders are piling up and I’m getting too frustrated with the rotary / motors burning up at 1motor : 1cup - it’s actually costing me more than I’m making ![]()

ideally would like to find local subs to get these out the door (shipping cost also not worth it) until I can get mine running smoothly. I ordered 10 more motors to have on hand…fml

@jkwilborn & @bionicback321 hope all is well.

Any update on yours Paul? I lowered the power going to the new nema23 motor… Burned up again.

Anyone know if I could just take the factory motor off the Y-axis and attach to the rotary? (Since that motor obviously works with whatever setting I must be missing)

This shouldn’t keep happening with your motors. I think you have some other anomaly occurring. If you have the same motors on the other axes, I’d think there is something fishy somewhere.

I’ve run the ‘crap’ out of these along with major abuse from change acceleration values and such. Haven’t lost a motor yet, so I’m wondering what’s going on with yours.

Add to that it’s summer here and the day temperatures are pretty consistently in the low 100’s F and I leave my machine on all day with no issues.

Can we examine the motors (at least one that works from the other axes and the rotary) and how they are wired/setup with the motor controller.

![]()