Hey all,

First off wanted to say I am loving LB and its capabilities! Most solid purchase I have made thus far on my lasering venture.

I am trying to set up a rotary and after searching the forums all night am seeing a LOT of people having relevant issues.

One thing I really need to figure out:

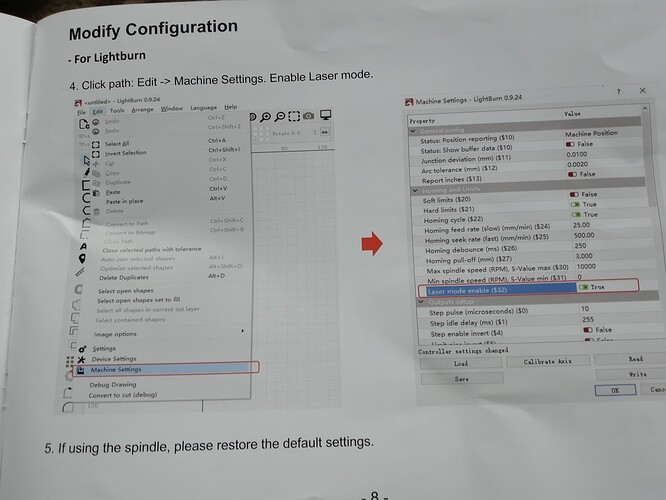

Lets pretend I am a dummy and during my trial setup of the rotary I changed the idle speeds on my machine settings without writing down the original settings… Rotary still not working but how can I get my original settings back if they are unknown?

Chinese Red & Black / OMTech 100w

Ruida RDC6442G-B(EC)

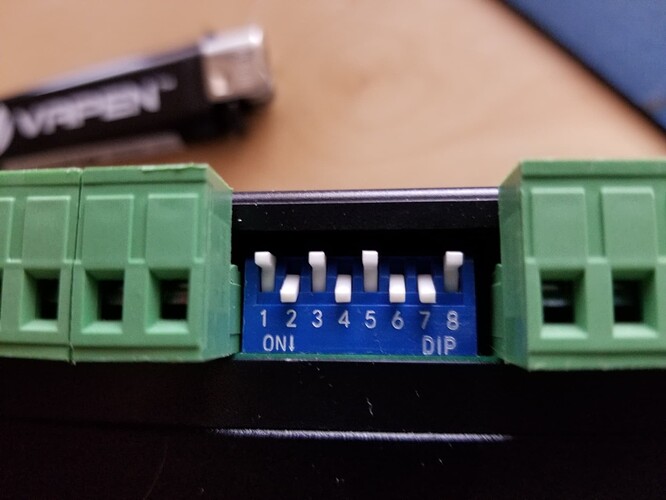

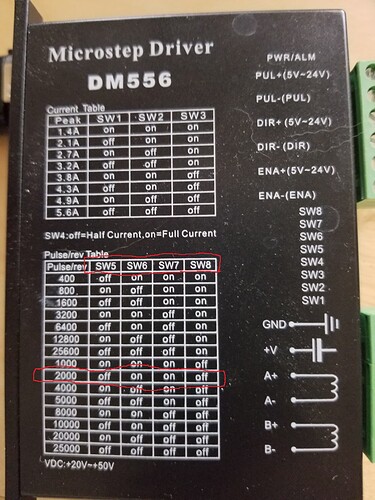

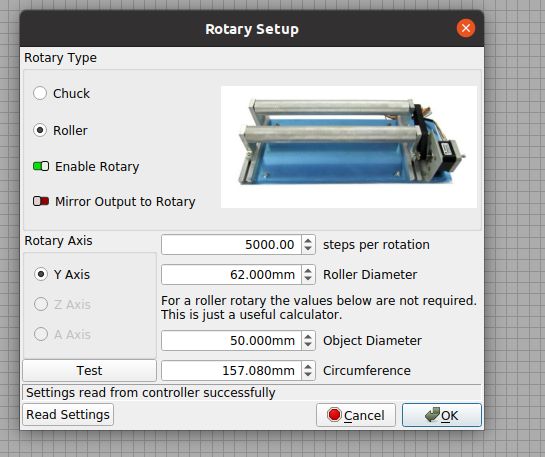

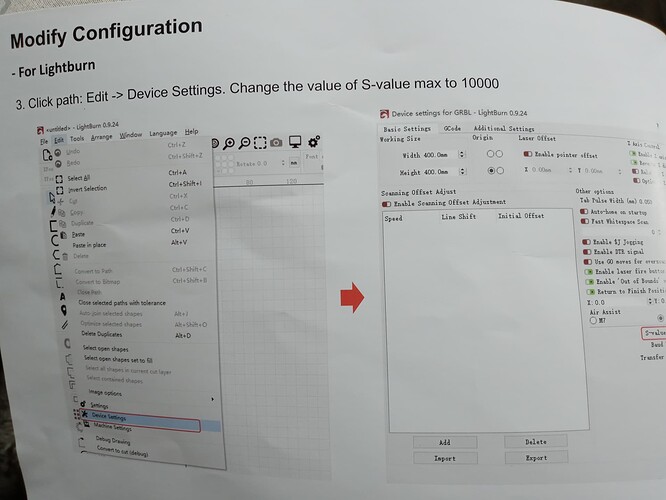

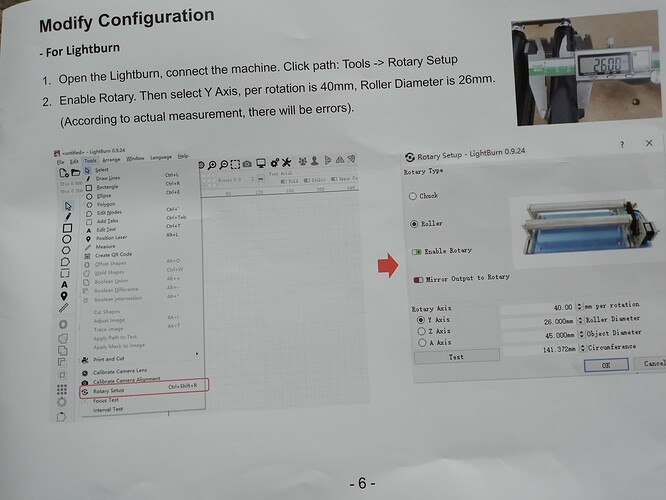

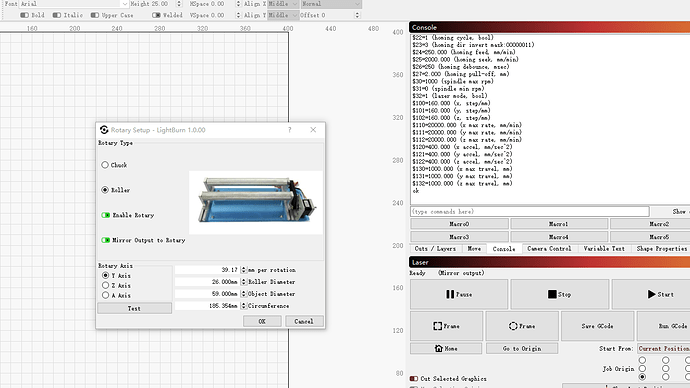

FoxAlien Roller Rotary (Their setup instructions for LightBurn were not options in the current version / could not find some of them as per their instructions). Their instructions mention 40mm per rotation but all i can find is “steps” per rotation. Regardless I tried setting it to 40 “steps” instead of mm and it keeps going back to the default 10,000 (read from controller?).

Steps per rotation- every time I changed it and did a test, no matter if I set it to 2500 or 10000 it rotated about 1.25 times and went back to normal position.

Thought I would give it a whirl and do a test run, hit Start and the rotary went flying around upon startup - flung the test tumbler right off of it. This is why I read the setup info from LB And per the note towards the end, changed the idle speeds. (Although I was frustrated at this point and didn’t make note of original settings).

I think I burned up the stepper motor trying this out so I am awaiting a new one. I had the machine on and while I was playing with setup, the motor started making a beeping noise and got very hot. Now it does absolutely Nothing, cannot get it to spin.

Unplugged it and hooked Y-axis back up, turned machine on and got a horrible growling noise when it tried to Home.

So I hit escape, tried manually moving the axes and they both slammed past the limits. I think i have fixed this part though but am taking a break from it right now.

Happy Mother’s Day to all! Going out for a bit then will check back, hopefully one of you genius LightBurners can help… Thanks in advance!