Hello

It is my first post and first problem i cant solve. I try to set up rotary axis, but whatever i type in steps per rotation, the rotary turns im exacly the same way. Only changing a roller diameter make device rotary more or less.

Hello

It is my first post and first problem i cant solve. I try to set up rotary axis, but whatever i type in steps per rotation, the rotary turns im exacly the same way. Only changing a roller diameter make device rotary more or less.

I use y axis

You need to give us more information if you would like help.

What kind of rotary, chuck or wheel?

Who makes it?

How many steps/rotation is your motor?

Gear ratio of the motor to drive wheel?

If it’s a wheeled rotary, the ‘driving’ wheel diameter.

Are both made by the same people?

I hope you are not trying to make both of them work with the same settings…

You will have to know the gear ratio to get the wheeled one to work properly. Finding out by trail and error could be time consuming.

Both of them you need to know how many steps/rotation for the motor. For the rotary that’s all you need for setup, as it has to compute the surface speed, which requires a radius.

For the wheeled, you need to know how many times the motor rotates to make the driving wheel rotate one turn, that’s the gear ratio.

Post a link to them and contact the supplier for this information.

I just need one answer:

Why nothing changes when I am setting different values in the steps for rotation field?

It doesn’t matter if there is 1 or 10000 - rotary behaves the same way.

That is my problem.

I’d like to give you one answer. I don’t have one, with the limited information you have given me. I don’t know anything about where you are in the software, how your machine is setup or if it’s wired right or even turning the right direction.

You need to calm down and lets start at the beginning.

You haven’t told me the steps/rotation of your motor?

It sounds like it turns. Does the driving wheel turn away from you when you move the rotary with the down arrow?

Hang in there…

Rotary seller told it should be connected to y. I dont have any controller for u axis. But i can make a test in lightburn and it is move. I can also make it move using buttons which moves laser head in forward and back direction (not left-right).

My stepper motor driver is set 6400 steps/rotation

Hopefully that is correct…

Now that you know that, you need to figure out how many revolutions the motor makes to one rotation of the driving wheel. I.E. the ‘Gear Ratio’.

I don’t know how you could sell a rotary and not be able to give the user required information such as the motor/wheel ratio. It is absolutely required.

The only other option would be to program a line or rectangle and computer the differences in size programmed and that produced.

I suggest you find/ask the manufacturer.

![]()

Chuck type rotary ratio os 1:3

I assume the ‘wheeled’ rotary is 1 to 3. The chuck rotary has no ‘wheel’ to have a ratio.

So one turn of the ‘wheel’ on your rotary is = steps/rotation times 3 (ratio). That should give you one rotation of the wheel for each rotation of the motor. Or 6400 * 3 = 19200.

But i still have problem with lightburn, whatever i type in steps per rotation, the rotary spin just the same way.

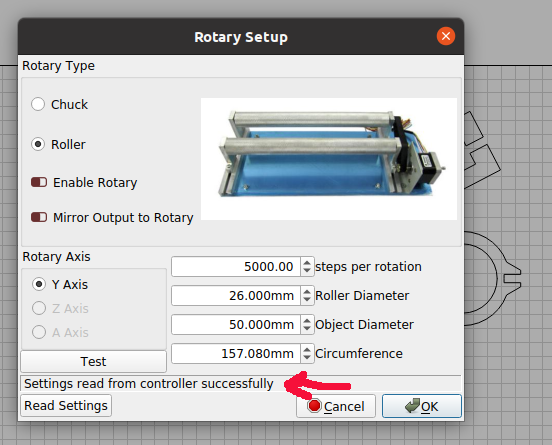

Where are you entering this information?

Can you do a screen shot for confirmation?

Assumption it’s in this window?

If so, does it say “Settings read from controller successfully”?

Since you won’t listen to me that the Ruida 6445 used the U AXIS for the rotary! Read this forum.

I have a 6445 ready to install. I haven’t installed it yet because I haven’t acquired the rest of the stuff to install a U axis.

I’ve read numerous threads around how people are using the Y on the 6445 controllers. Add to that there are patches to use the U axis for a rotary on the 6445.

So It’s very confusing… Mine is a 6442.

There is a link to a thread related…maybe…

A couple stated it worked with RDWorks but not Lightburn…

Run mine off the Y axis for now, have the motor driver, just need to install it for the U axis.

But these guys have surprised me before…

He keeps going on how the settings don’t take so It sounds like his is set up for the U. It would be easy to check by swapping the Y to the U at the controller and testing. It takes about 2 minutes for the machine to figure out the home fails but everything should work after that.

I use my X axis for my rotation and adjust $100= to what It takes to move 100mm when I have 100 in the jog. Adjust $100 up or down to get distance needed.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.