Hi all,

I have a China Blue laser with a 500 by 300 bed. I have been using it for about 2.5 years and have had issues trying to use the Rotary Setup in LB. In the past, when doing Rotary work, I have stayed away from Rotary setup and just done a test burn of a fixed height rectangle on a round object with a piece of tape on it , measure the height of the cut rectangle and then in Machine Settings scaled the Y axis according to the height of the rectangle obtained. This method seems to work but is a little tiresome to do each time I need to burn something with the rotary attachment.

A few details when I try to use Rotary Setup:

- Y driver board switches are set for 5000 pulses per revolution.

- Drive sprocket diameter is 16.4mm, driven sprocket is 24.6 mm, so gear ratio is 1.5. So pulses per rotation should be 7500.

- diameter of rollers is 25mm.

- I have used a Sharpie to mark a reference line on my rotor and a fixed point on the rotary attachment to align the mark on roller with.

- I manually jog the roller so marks align.

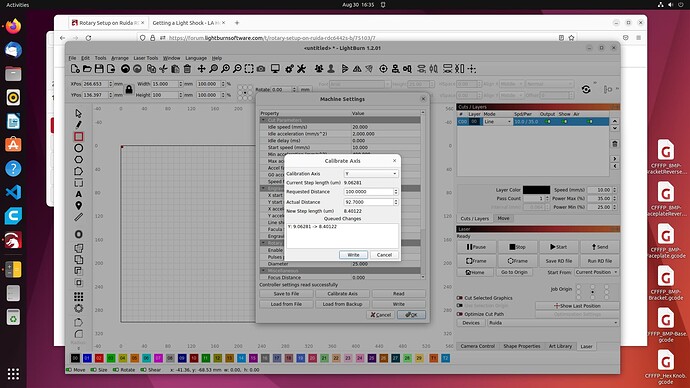

I enable rotary setup and set with information above. When I do a Test the rotary does not return to marked location. I have to adjust the pulses per rotation to 8000 and then Test returns so marks are aligned.

As per LB Rotary setup video, I power cycle the laser.

I do a test burn on a piece of tape of a rectangle that is 20mm wide by 100mm tall. When I measure the resulting rectangle by removing the tape and places it flat on my desk, it only measures 92.6mm.

I am confused on why it is not 100mm. Can anyone see something wrong with what I am doing or is there something I am not understanding?

Any help, clarification, etc would be helpful.

Thanks.