Hello colleagues, I have a question for you, how do you deal with the production of small parts. For example, I make snowflakes etc. of different sizes from leftover plywood. However, I have to sand them afterwards and that is a problem. As they get smaller, they break more often. I would like your opinion on how to do this better. I don’t use adhesive tape because these are small areas of plywood.

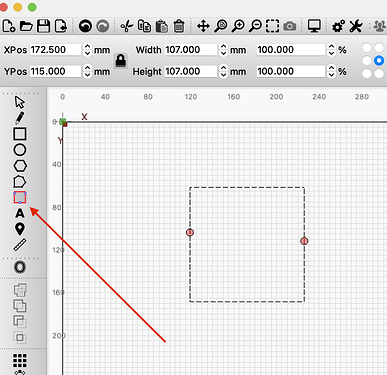

I use “bridges” for the small items, grind them and break them out afterwards. It works best with whole sheets but I also use it for leftovers.

You can also tape them, but then it takes 100 years to remove the small tape residues ![]()

I’ve never tried it, but if you’re doing a lot and can justify the outlay, a vibratory cleaner filled with walnut or corncob may do a really good job.

Also known as a case cleaner in the firearms ammunition reloading circle.

Would sealing / finishing the wood prior to using laser make it easier to clean?

I’m a newbie and just starting to figure things out too.

what kind of bridges are you referring to?

do you have a link to a video of what it looks like?

I mean that in Lightburn`s own documentation there is a fine explanation of the feature and a link to videos

Ummm, so you use bridges, that way the parts don’t break off and you go over the surface with a sander or hand sandpaper. Then you break them off… am I getting this right?

I’ve made some attempts with hair lacquer. The result is mixed and dependent on the surface. For smooth surfaces that can withstand acetone, the result is best. (Acetone to Remove Lack with after lasering)

Sorry, forgot this part, yes that is the way I do it when the items are too small. The trick is to find the fine -tuning of the size and thickness of the bridges, then they only just hold the parts but do not give too much post -processing after parts are broken out.

that’s good, I’ll try using acetone to clean the laser spots ![]()

Not really a solution, but I’d just spray paint all of them with white color ![]()

… why not, it’s probably the fastest solution. ![]()

I’m in the camp of sanding before removal from the cut sheet of plywood.

Alternatively, you could try mounting them on a flat block of wood and lightly sanding them on a sheet of sandpaper attached to a smooth/flat surface.

You can attach the parts to the sanding block with contact (shelf) paper as the adhesive will hold well, yet still allow for the parts to be removed.

I use adhesive backed paper masking. Comes in several widths.

You only have one piece to peel off each flake with a pair of tweezers.

Do you not have any air assist?

I seal everything wooden I engrave. You can use readily available latex sanding sealer applying with a brush or foam brush.

Something to try that’s used for cnc jobs might work, put strip of 2" painters tape on piece of wood and put the snow flakes on another then use CA glue on one piece and activator back of piece with snow flakes and join them together then sand them, easy enough to then remove from tape. Took longer to type this than to do it.

Try white vinegar. It works well for me.Just put it in a spray bottle and lightly wipe it.

Just take what’s left of the leftover sheet, place it on your workbench. Drop the pieces back into the voids where they were cut from. Run an orbital sander over the sheet with the parts in place. Some might pop out if they are real small. Just adjust the number of piece you sand at one time until you find the right number that will stay seated in place. Worst case, place the sheet good side down, pop all the little piece back into the sheet, good side down then run a few strips of blue painter’s tape on the bad side to hold in place when you flip everything over to sand.

thank you!

Maybe do a pocket or deep engrave of the snowflake in another piece of wood so you can have basically a mold to hold them in place while you sand them. Just a thought