Sorry to step in.

M3(CW) and M4(CCW) on the CNC is different than on the laser M3(fixed power) and M4(dynamic power).

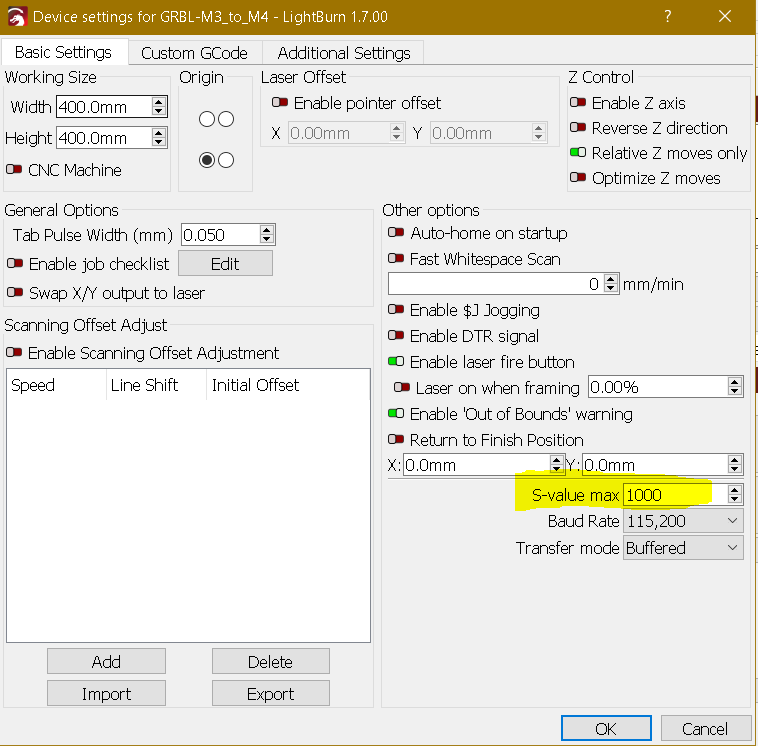

You could try a Custom GCode machine wit more options to adapt to your CNC, remember to set Lightburn S-value max to 255 because your controller only accept values between 0-255.

Check also if you have some setting for the PWM frequency as lot of laser modules usually work at 1000Hz.

Maybe you could create a UCCNC profile for laser and other for CNC so you don´t miss any settings.

Also you could read the following topic

.

You could try with your UCCNC laser plugin save the gcode of a small image and compare the output with the generated from Lightburn.

If the above solutions don’t work you have to save gcode and then edit with Notepad++ and auto replace commands per your machine requirements.