Welcome and thank you for your interest in LightBurn. I will try to address your questions, each in turn, but I also suggest you review our documentation, as many of your questions are covered in detail there: LightBurn Software Documentation

In particular, walk through the Simple Project section, to gain some of the basics for how LightBurn works.

Reading this, you seem to understand how LightBurn decides what to fill, but this is a good resource explaining this in detail. I would like to “see” what “better appearance but it’s not perfect.” means to you.

I think this may be an issue of understanding how Layers work. I would need to see an example of what you are wanting to produce to offer any direct workflow suggestions.

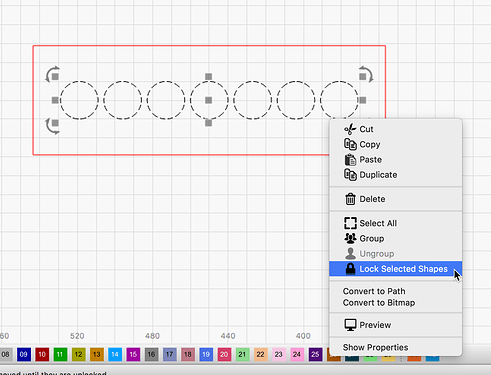

Select the shapes you want to lock, then right-click the selection to bring up the context menu, where you can then ‘Lock Selected Shapes’

Selected shapes can be deleted by hitting the delete key. I may not be understanding what you are after here, so please clarify.

I am not understanding this question, as the cut settings (and more) are saved with the file. You will need to be a bit more specific as to what you are asking here. What did you expect to happen that is not?

Yes, you can have your file(s) hosted on any accessible storage (Local, cloud, removable(flash drive)), or sent to the laser via USB or Ethernet if supported.

Many objects created in LightBurn are special shapes called ‘Primitive Shapes’. Text object are one of the Primitive Shapes allowing you to do things to it, like change to Bold or curve the text, pulling on the ‘Blue Dot’. To disassemble a Primitive Shape, you need to convert it to paths first. You should then be able to move the desired parts of this ‘text’ to a different layer.

If you manually move the head, LightBurn would not know. If you move the material, LightBurn would not know. The ‘Start from here’ button usage is for when the cutting process was interrupted, and you want to restore and continue, but this requires knowing where the laser is in relation to the material. If either of those change…

You can try to line things up again, then flip the processing sequence, front to back changed to process back to front, as an example, then monitor the job and stop when the new cut meets the old one.

Thanks for the pleasant comment, it is always nice to hear folks are enjoying our efforts. ![]()