Anyone familiar with a Sihao laser and the rotary tool? Bought a laser from a lady whom husband had it. She had no manual or software for it. I’ve tried reaching out to Sihao for a manual and have had no luck. I can get the laser to burn fine with wood, however the rotary seems to not respond the way I want it too. Watched tons of Youtube videos but still having issues.

How is it responding that it is not what you like?

Basically, you unplug the Yaxis and plug it into the rotary. Then you disable Home operation because there is no Home position in the rotary. Finally, you disable limit travel alarm messages because the rotary has no travel limit.

I’ve done all that, and it works fine. The problem is it is like it isn’t reading the tool path correctly. I put in my diameter and then measure circumference and set that as my “tool path”. When I import an image and scale it, say to 1/4 of the “tool path”, it shrinks it so close together it is unreadable. Example, I am etching glass and to get an image that is basically on one side of the jar, i have to have the image the same size as the “tool path” which is the total circumference.

Sounds like you have a scaling issue. I suspect it is in your workflow process, but we need to make sure the rotary settings are correct.

I recently did a “study” with my rotaries and put it in a posting. Try following all the steps I outlined for your rotary type, and then see if it works for you.

Basically, if it is 75mm in Y in your drawing, it should wrap 75mm around your part. If the rotary parameters are not set accurately, you will get scaling issues.

Not sure why you are doing this, or what you really mean, but it sounds like an unnecessary step. If you are actually using an image file instead of a raster, I think doing an image on glass would be very difficult. You do not get a more burn, less burn like on wood. If you upload the image, maybe we can better understand what you wish to accomplish.

When I measured the chuck (258.76 mm) and put that in, it did a quarter rotation and then came back to the same spot.

The tool path was the circumference of the jar. Then I would scale that to 1/4 and 1/4 to try to burn on opposite sides. Seen it on a youtube video. But in theory, I should just be able to dump an image out there, scale it to where I want it and go, right?

I followed your steps. My three options under rotatory is the cirm, diam and steps per rotation.

something is either off on the Y driver or scaling issues some place else.

I believe, this isn’t really true, as the machine can’t operate without an origin. Like any other of these lower cost machines, if you power it up with homing disabled, the current position is considered home. This is how you home a machine that doesn’t have the home switches. This doesn’t make your Y axes infinite.

When you place the rotary as the Y axes, the controller really handles it like it’s the Y axes… that’s the whole idea.

Not sure what you’re doing here … the rotary setup is relatively simple. It’s much easier to check the proper configuration of the steps/rotation via the rotary setup gui.

If you press the test button in the rotaries gui, does the chuck make one complete ration and then back one rotation?

It is a chuck type?

A tool pah is usually where the head has to move to complete the job. It sounds like you’re using it as a definition of the work area.

Your terminology may be tough on some people.

![]()

I measured the chuck as the outline that MikeH had listed. When I setup the rotary (chuck style) it tells me it read the settings successful. When I hit the test button, without changing any settings, it makes 8 and a half rotations. If I change the circumference to the same as what the main body of the chuck is, which should make one complete circle, it only goes a quarter turn and then goes back to start.

I haven’t disabled home position, instead I have a setting saved with the axis points where I want it to start for this one product. That way I just click on the title and hit go and it takes me to that axis points.

The gui test button should rotate it one complete turn and back. If it doesn’t, it isn’t setup properly.

Chuck diameter doesn’t matter with the test button, it’s only function is to rotate either the chuck or the roller one turn and back.

Is your chuck connect directly to the motor?

The chuck motor and assembly is connected directly to the port on the laser with the OG cable. As stated prior. I bought this from a widowed woman who had no software or manual on this laser. I do agree with you, something isn’t set up correctly with it.

Suggestions?

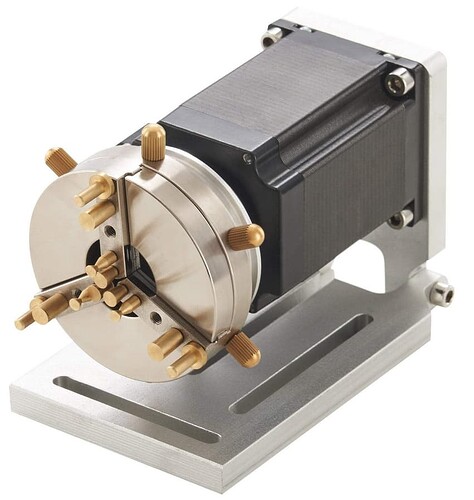

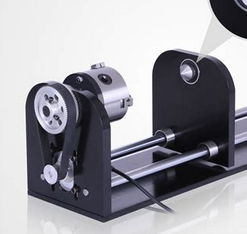

Both of these are chuck type rotaries.

This has the motor driving the chuck directly

This motor has a ratio and has to be applied to the steps/rotation

You got the same information as my new machine contained… zippo ![]()

What settings are you using? Your profile says a grbl and it’s stated as a Ruida. Assume this is a new addition to the family …?

If it’s a Ruida, the see if the rotary is setup this way…

![]()

Ok, I am following you. I just looked and my 5,6,7,8 settings are showing 5000. With no manual, what are the calculations to figure the ratio?

top pulley has 72 teeth / 68 mm

bottom/drive pulley has 24 teeth / 34mm

I tried a ruler and marker to find the the points on both pulleys. They ran my Y axis counting how many times the drive pulley makes a full rotation compared to the top pulley. The top pulley doesn’t get a 3/4 rotation before i limit out on Y axis.

Using your motor driver setting of 5000 steps/rotation, you’d need to do some math…

72 teeth / 24 teeth makes it a 3:1 revolution, so your steps/rotation should be 3 * 5000 or 15000 steps/rotation.

The motor would make 1 revolution with 5000 steps/rotation, it takes three rotations of the motor to cause the chuck to rotate once.

Make sense?

![]()

Yep. Just tried it. Ended up having to take it up to 17,000 to get one exact rotation.

Thank you so much for the help. Ready to start playing with it now.

Great you have it going…

Have fun

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.