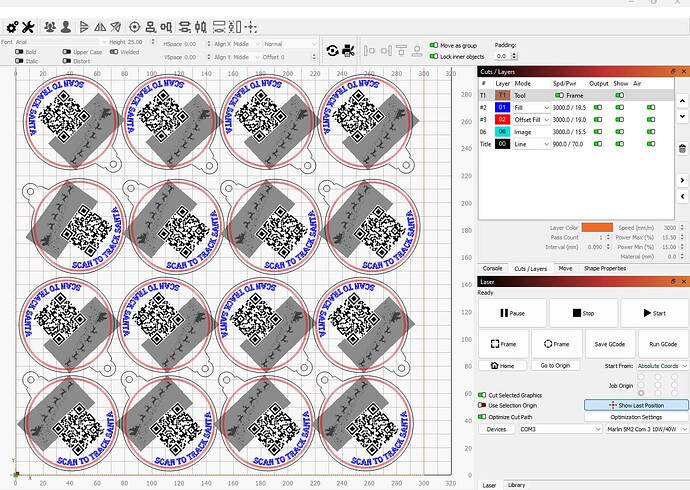

Ok… Here’s my weirdness:

Snapmaker A350 with 40W laser, Firmware V 1.17.17

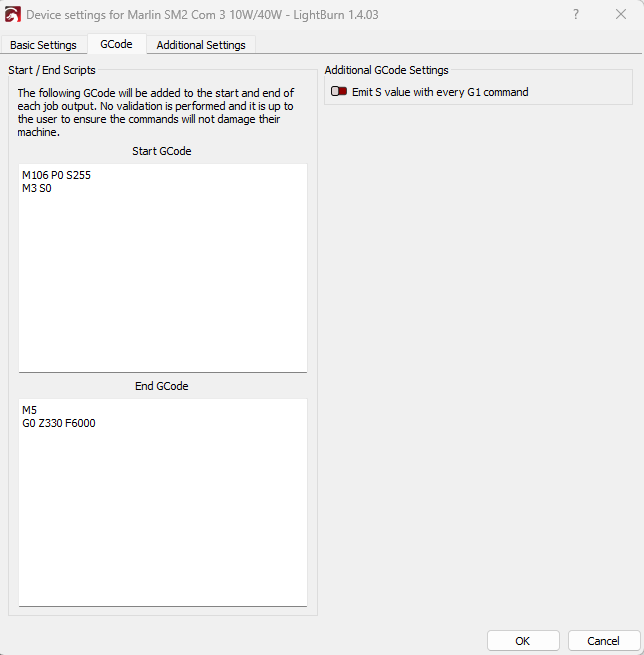

If I have a layout that is arrayed in Lightburn and I select one of the grouped objects to burn (to test settings) it burns normally and the machine returns to end GCode (M5, G0 Z330 F6000).

If I select the next grouped object (after making minor power adjustments), select Go to Origin and start the job, the machine goes to the correct job location and starts the job, BUT, the machine runs at some unknown slow speed over burning the job and I have to pause and stop the job.

I then have to restart LB and do the second selection and it will work fine for that job, but subsequent jobs will run at the reduced speed and over burn. This also occurs if don’t even change the selected object, just selecting Start and I get the slow speed issue, it just remains stuck at the slow speed instead of the speed set in Cuts/Layers.

I changed the power on all layers to 1% for testing purposes, left the speed settings the same as in the original project. Ran the job with only one object of the array selected, ran fine in 7min, 18sec.

Went to run it exactly the same after the first one finished. Didn’t change a single thing, same object, just clicked Start and it took 18 min. to run, this would have seriously over burned the job.

Here is the start and end of the Gcode from both runs, Good and Bad:

GOOD:

Initial run, Get Position, Set Origin, click Start:

Waiting for connection…

ok

X:0.00 Y:0.00 Z:0.00 E:0.00 Count X:11280 Y:9560 Z:32580 B:0

ok

X:0.00 Y:0.00 Z:0.00 E:0.00 Count X:11280 Y:9560 Z:32580 B:0

ok

Project loaded in 75 milliseconds

Starting stream

M106 P0 S255

M3 S0

G21

G90

M8

M05

G0 X247.74 Y9.341 F3000

G0 Z0

Layer #2

G91

G1 X0.042 I S2.5

G1 X-0.083Y0.1 I S0

G1 X-0.072 I S2.5

G1 X-0.081Y0.1 I S0

set air pump switch: open

G1 X0.075 I S2.5

G1 X-0.048Y0.1 I S0

G1 X-0.088 I S2.5

G1 X-0.042Y0.1 I S0

.

.

.

M05

G0 X232.687 Y71.709 F3000

G1 X232.552 Y72.063F900 I S2.5

G1 X232.249 Y72.724

G1 X231.864 Y73.341

.

.

.

G1 X232.792 Y71.761

G1 X232.717 Y71.71

G1 X232.687

M9

M05

G90

M5

G0 Z330 F6000

set air pump switch: close

Stream completed in 7:18

close Laser control

BAD:

Subsequent run, same object, just clicked Start

Starting stream

M106 P0 S255

M3 S0

G21

G90

M8

M05

G0 X247.74 Y9.341 F3000

G0 Z0

Layer #2

G91

G1 X0.042 I S2.5

G1 X-0.083Y0.1 I S0

G1 X-0.072 I S2.5

.

.

.

M05

G0 X232.687 Y71.709 F3000

G1 X232.552 Y72.063F900 I S2.5

G1 X232.249 Y72.724

G1 X231.864 Y73.341

.

.

.

G1 X232.792 Y71.761

G1 X232.717 Y71.71

G1 X232.687

M9

M05

G90

M5

G0 Z330 F6000

set air pump switch: close

Stream completed in 18:00

close Laser control

Ok more testing reveals that running the job after the first run, the speed is approximately 1/2 the correct speed.

But…

After the job completes and the machine returns to M5 G0 Z330 F6000, If I click the Saved Positions (I have the origin position saved and the machine goes to that location) and run the job, it will run correctly, every time. But I have to go through the Click Saved Positions sequence for each job.