Hi, i think i found the issue.

I bought my machine recently and i’m new to lasers so it took me a while to figure this out.

i tried resetting all settings in lightburn, reïnstalling etc → same issue.

i then tried RDworks (came with the machine) → same issue.

so it had to be a machine issue.

i tried to tightening belts, lube guide rails etc, no change

i realigned the laser again, it had not deviated (visibly) from when the machine was just bought.

then i turned my attention to the powersupply, down the rabbit hole.

i tried to get the wiring diagram to my specific laser from the manufacturer, but have not recieved any answer yet.

i went on my own and looked up parts numbers etc to figure out myself what the wiring should look like.

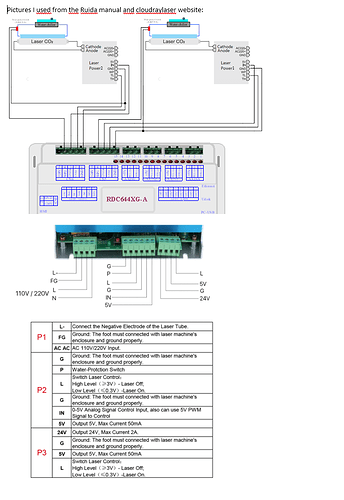

on the website of cloudray i found my exact psu:

its branded ZYE but that is the direct manufacturer of the device, cloudray rebrands them as their own.

the wiring diagram to this power supply is different from the other types with only 2 connectors.

i compared the wiring diagrams and found out my PSU was wired for the wrong type of PSU.

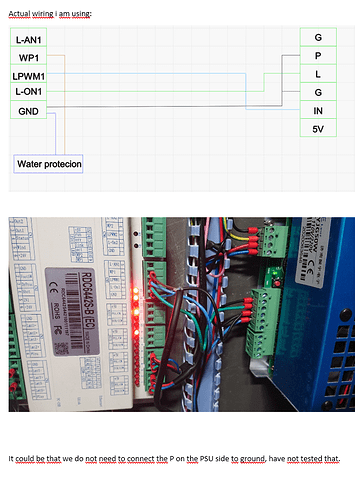

I rewired the PSU and ruida (changed from analog to PWM also)

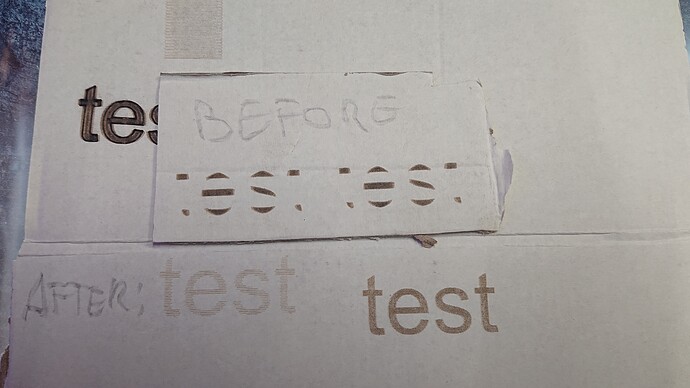

and tadaa! laser works like a charm, very accurate, does not skip thin parts or anything, Ican engrave at 400mm/s 20% on test piece of cardboard with no issue.

I guess the manufacturer of my laser recently switched PSU’s and dit not update their wiring schematics in the assembly line.

TLDR: check PSU wiring + switch to PWM-signal instead of analog

PS: Don’t touch the wiring or anything inside the psu/controller part of the laser before unplugging it completely from the grid!