I have 250 flashlights to put a logo on, but because my other rotary is being used to make a whole-lotta political style mugs (thank you Mr. Trump from a greedy old Canadian), I needed to make something so I didn’t interrupt my current projects.

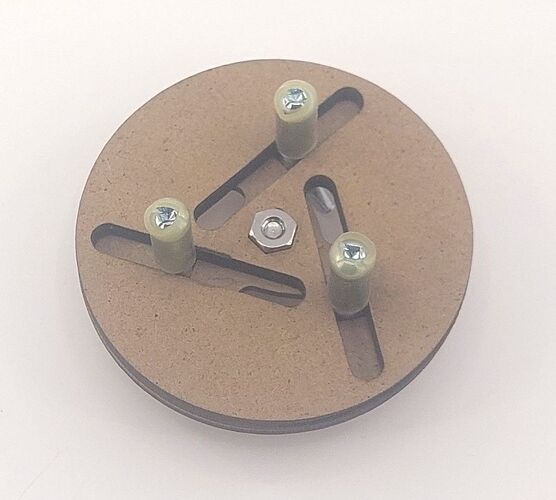

I decided on a longworth chuck. They are very easy to make. This one is made of things I had sitting around: MDF, 8-32 bolts (same size as M4), wingnuts, plastic spacers, surgical tube and rivet nuts.

The rivet nuts make it easier for the bolts to slide in the slots.

I attached the chuck to a stepper motor using a bolt that I stuck into the pulley attached to the motor. I attached the motor onto a piece of wood, put it in the Neje Max4 and it works great.

The entire project took less than 3 hours to cut, assemble and get working. It would have taken less time but I had to make a Timmie’s run in the middle of the project - fellow Canadians will understand.

If anyone is interested in the LightBurn file let me know and I’ll attach it.

Awesome!! You could make lots of these and have them set up for each job. Or use it as a base for a quick-swap mechanism.

Robert beat you to it a couple years ago.

https://www.etsy.com/listing/1566770378/all-aluminum-self-centering-chuck-or?ref=shop_home_active_1&crt=1&sts=1&logging_key=7741e2ade7b2cfdcd3ff865832a03da46284507f%3A1566770378

This one is adjustable from a diameter of 68mm down to 12mm. Rotating the rear plate and the front plate opposite directions increases or decreases the size. Tightening one or more of the wingnuts holds it in position. It is working great on the flashlights which are 22mm diameter where it grips and are 93mm long. If I wanted, I can easily make a larger unit that will do a larger diameter. I’ll probably end up making a better one out of acrylic for the plates, motor mount and base.

I’ve made a few longworth chucks for my lathe over the years. Keeping people from borrowing them seems to be a problem. Although, it is a lot easer making a small one on the laser than it is making a large one using a router. I used to use them a lot when I made larger bowls

I would be interested ![]() Though it’s not extremely difficult to design, but since you already did it..

Though it’s not extremely difficult to design, but since you already did it.. ![]() I’d like to include it into my wiki pages for rotary setups.

I’d like to include it into my wiki pages for rotary setups.

I’m with Melvin I wood be interested, thank you…

Cheers Merlin…

Here it is. This can be scaled up or down by resizing the entire thing. After doing so, ungroup each one. To get the proper slot size, delete the shapes around the blue tool lines (T2) and offset the tool paths to half of whatever diameter your pins/bolts are. The centre circle and nut will need to be resized as needed. I made this to use as a rotary chuck but it can be easily adapted to be used as a centre position jig like the one Albroswift mentioned just by adding a larger circle or square to “Plate B”. Using it like that never even occured to me but I intend to make one because it looks like it would be handy.

Please note that you will need to enter your own cut and fill settings for your laser. This one was made with MDF but it can easily be made using anything that your laser can cut.

LongWorth Chuck.lbrn2 (117.8 KB)

Thanks CS I received my email…

Cheers Merlin…

Thanks for the file! I can see this as being useful on a Roller rotary with uneven end diameters, even though you did not say exactly that. I can see making these big enough to do coffee cups on a roller, orientated properly of course.

Nice job on a quick jig. But, uh, uhm, do you have a pic of the mug? Inquiring mind wants to know. Or will asking for a friend work?..![]()

Unfortunately, the mugs wouldn’t be appropriate for this forum. As much as I would like to, I thing the moderators would not approve. However, the popularity of the mugs has resulted in my getting into t-shirts, for which I also have a request of 300. I’m also getting into sublimation so I can make the pattern in colour. All paid for by my profits. Thanks again Mr. Donny T!

Yeah, I understand. Many sales and best wishes to you on your mugs and T-shirts.

I would be very interested too.

Hi

And what laser do you have?

I have a 20watt diode and will it cut MDF?

I’m interested as well in the files for Temporary 3 Jaw Chuck

Thanks

I have two CO2 and a Neje Max4 with the 20W diode module. These were cut with the Neje. The fill was set to: Cross Hatch; 3500 mm/min at 90% power; 1 pass. The cuts were set to: 300 mm/min; 90% power; 1 pass. Plate A is 6mm MDF. Plate B is 3mm MDF. I used the same cut settings on both because I was too lazy to change the setting for the thinner MDF.

Your settings on yours will probably be different because I have found the Neje to cut similar to a 30W module.

The file is attached to one of the earlier replies here.

This is a great idea and is probably the best way for me to start with a rotary, since I’m working from an almost-zero budget.

Would you be willing to post a couple of pictures of the chuck in use and how you have it attached to the stepper? I’m not even half-way through my first cup of coffee this morning and am struggling to picture the setup.

Thanks!

Thank you for LongWorth Chuck.lbrn2

Bart