Hi! The cnc machine on GBRL CO2 slowly engraves. How to speed it up? Thanks

We have no clue of what kind of a machine we are dealing with. Your profile does not list a machine.

We are pretty much helpless without some kind of information about what kind of a machine is having a problem… Without the basic information, there is nothing we can suggest.

![]()

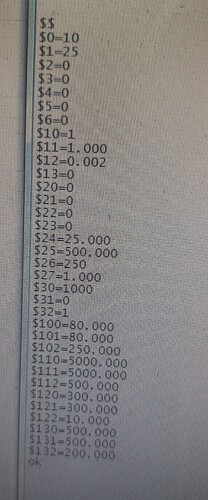

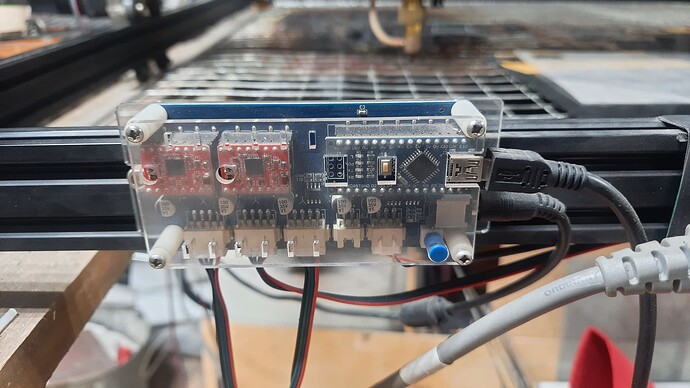

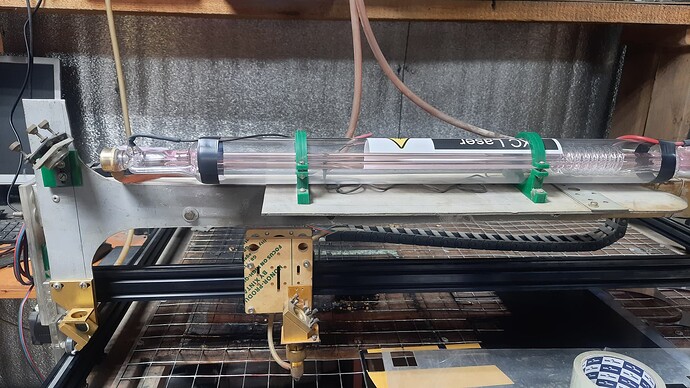

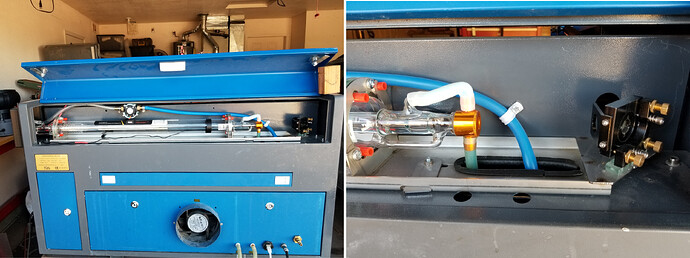

Homemade CNC machine CO2 40w 1m x 1m. Made a long time ago, I do not remember the characteristics, but I attach a photo, an arduino is used. It works fine, it cuts as it should, but the engraving did not work out properly from the very beginning. it works very slowly. I use Lightburn. I gave the command $$, maybe I didn’t finish something? tell me how to make it print quickly

Perhaps the engraving layer settings are vastly too slow.

Perhaps you’re thinking in inch/sec with LightBurn set to mm/sec, so that the numeric speeds are too slow by a factor of 25.4.

Perhaps the units are mm/min and you’re thinking mm/sec, which would be too slow by a factor of 60.

If checking those don’t perk things up, post the lbrn file so we can take a look at it.

I’d pay attention to @ednisley but would add that it’s never going to be very fast in the Y direction.

You have the huge frame for the Y gantry, mirror 1, tube, head/lens/carrier and lps are all carried around on the Y gantry… making for a high Y mass. This hinders operational attributes.

The current limit of your drivers will keep it from accelerating very fast, taking time to get up to speed.

What size motors are you using?

I’d suggest you check and see what kind of acceleration values you have on the Y axes. Edit → Machine Settings → Output Setup …

This is my CNC3018, which is screw driven, so it’s slow… This same value on my China Blue co2 is 8000mm/s^2 … a bit of difference… What is yours?

I suspect your Y speeds (you didn’t mention) may not be attainable with this, but I’m making many assumptions. There is a site you can enter the acceleration values, axes length and intended speed and see if it’s possible for it get to requested speed. This will tell you how long it will take to reach speed and how much distance will be required.

If this is the issue, you only cure, besides tuning it it’s best ability, is to do scans the go from the bottom up and limit the use of the Y axes, allowing most of the work to be done the X axes.

My machine has motor drivers that can supply more power to the axes and I get faster jobs along with higher top speeds…

I love a good diy, I love yours, the way you built it slows the Y axes down substantially… unless you made adjustments somewhere…

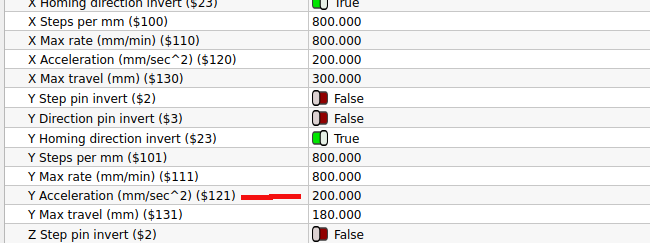

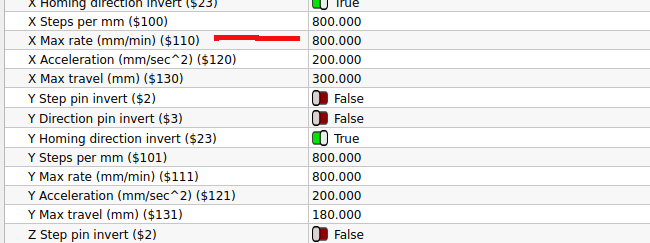

Let us know the values of your variables. From the console you can type $$ and it should dump all variables to the console and you can then cut/paste to a file and post it or just paste in the values…

If possible, a screenshot of the output section of the machine settings cover all these and are not just ID’d by number like the $$ output will be.

Let us know what we’ve advised - compared to what you have… we’ll help you as much as possible…

![]()

Thanks, I’ll check the specifications tonight. I’ll send the skins. I forgot to say that when the cutting characteristics change, I can make the cutting very fast or very slow. But the engraving does not react to changes in speed, I put more or less and there is no reaction

We may have to look for other things, so hang in there…

![]()

I change the cutting speed without any problems, it should be slow, it will be slow and vice versa.

and the engraving does not change at all… one speed as in the video. The parameter is specified on mm/sec. made $121=1000, no reaction

There are other parameters such as the maximum speeds that are set within the controller.

This is a CNC3018 milling machine, but it’s X axes is set for a maximum speed of 800mm/m which is only 13mm/s.

Note: I keep forgetting to add, generally they recommend the tube coolant outlet be facing up so the bubbles will naturally be forced out…

![]()

You can try enabling G0 moves in the device settings window.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.