Thinking about picking up a fiber laser to go along with the CO2 I have. Thoughts on OMTech Fiber !

Dito… been working in the spousal unit for one… hoping when tax returns show up ![]()

I’ve seen the term of split laser, but can’t find anything for a dummy on it.

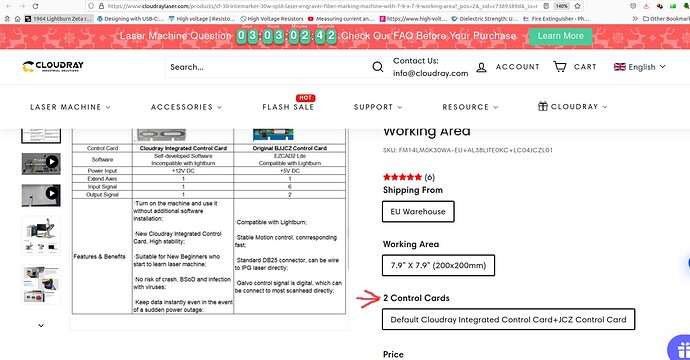

One of the machines comes with two control boards?

Yea it’s rather confusing…

![]()

The only thing I regret is getting a 300x300 lens. I have picked up a 110x110 and 150x150 but haven’t set them up yet.

Also do yourself a favor and research the laser manufacture. I picked up a JPT, they had the best reviews. One of the manufactures are complete garbage but I can’t remember what one it is.

JPT is a type of laser source unit inside the case. JPT doesn’t manufacture/assemble whole fiber lasers. Other types of laser source units are Raycus, Max and IPG. Raycus is probably the source most commonly used because it’s cheaper. JPTs cost more but offer a greater frequency range which is very useful for achieving different effects. Having more than one lens is good, they’re easy to change. The smaller the lens the more power delivered (over the smaller field size) as opposed to a larger lens covering a larger area but spreading the available power out.

I picked up my machine from Richard Zhang @ https://www.omglaser.com/ He’s a good guy to deal with and has good gear at good prices with good warranty. Might check his stuff out as well.

OMTECH builds a good fiber laser. The laser source within the machine is very important. There are more than 30 different brands for the power laser source.

I will share the two that you will see most often. Basically Made in China or Singapore. Raycus or JPT.

Raycus

This brand is cheap, and this is the main reason most of the companies use it, is not famous for a quality engraving and also have less warranty than other fiber power sources. This brand also has a small range frequency between 20 to 80 kHz, which makes it have a short range of engraving materials. In comparison with other brands, Raycus doesn’t offer too much advantage to the customer, but it can be very cheap, and as a result, machines build with this power source are low cost.

JPT

This Singaporean brand has a different laser power source, not as limited as a result of its Pulse Repetition Rate Range of 1 to 4000 kHz This brand is famous because it provides excellent quality, excellent engraving, stability at the time of work with their premium models, as JPT-X or MOPA.

OMTECH JPT MOPA M7 fiber laser is a solid well built machine. You will need to decide on the wattage and if you want MOPA or not. Wattage variables are from 20- 100 watt. The laser power is the amount of energy that can be produced by the laser over one second. It is also known as “average power” and “output power”.

Pulsed lasers may also indicate a peak power, which is a different parameter. The peak power is the maximum amount of energy reached by a single pulse. For example, a 100W pulsed fiber laser can easily reach 10,000W of peak power. This is because pulsed lasers do not distribute energy evenly over time as opposed to continuous-wave lasers.

The term MOPA is an abbreviation for Master Oscillator Power Amplifier . The master oscillator produces the beam while the optical amplifier is used for boosting the output power.

The light of marking lasers is generated in pulses. Generally, the pulse duration is non-adjustable. What is special about a MOPA laser is that its pulse duration is variable: Long or short pulses can be adjusted in steps between 2 and 500 ns.

Additionally, the laser parameters pulse duration, pulse frequency and pulse energy can be adjusted nearly independently of one another what results in high flexibility.

Furthermore, there is a difference regarding the pulse frequency itself: While the range of the pulse frequency of a so-called standard laser lies between 2 and 200 kHz, it lies between 1.6 kHz and 1 MHz for a MOPA laser.

MOPA laser offers more flexibility regarding the adjustment of laser parameters. Thus, the MOPA laser is extremely versatile and can be adapted to the material very accurately if needed.

MOPA lasers are optimally suited for marking naturally and colored anodized aluminum to create black markings without damaging the surface. They are also used for high-contrast marking of various other [metals ](e.g. nickel alloys, steels, titanium). For example, a MOPA laser creates a wide range of reproducible annealing colors on stainless steel.

Furthermore, MOPA lasers provide advantages regarding the durability of the mark after reprocessing: With the possibility of flexibly adjusting the laser parameters, high-quality markings that are resistant against multiple passivation and sterilization cycles can be achieved. That is why the MOPA laser is often used for marking medical products

You can also achieve better results with the MOPA laser for some plastics than with a “standard” fiber laser, for example regarding the contrast on black polyamide, black PBT (polybutylene terephthalate) or polypropylene.

Due to the possibility of adjusting the pulse duration, MOPA lasers are optimally suited for high-quality laser ablation or paint removal e.g. for day/night markings in the automotive industries.

I suggest buying the most powerful you can afford . It will save you on time to complete your projects especially if you want production.

Cheers in your decision making. ![]()

Sas

Thanks for the time to lay this out …

I see some of them advertised

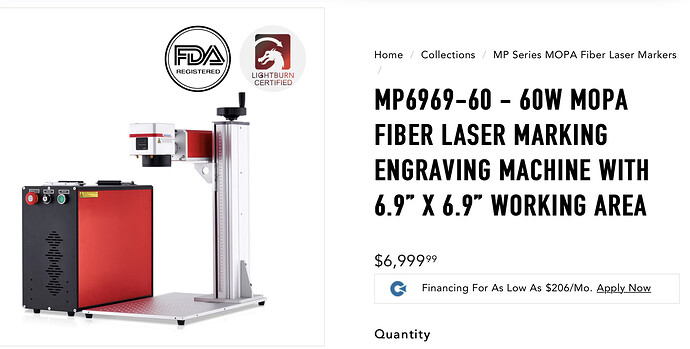

QS-P-50 LiteMarker 50W Split Laser Engraver Fiber Marking Machine

Can’t find a definition of a ‘split’ laser… ?

Thanks again…

![]()

The split laser system is like the one shown where the case containing the laser source and other electronics is separate from the tower and the user supplies the computer and monitor as opposed to the other option where the computer, monitor, laser source etc. are all part of a desklike unit.

Thanks… kind of made me wonder…

Any thoughts on it ‘comes with two control boards’?

Like in my first post?

![]()

The two control boards is something I’ve never heard of before. Not sure how you’d switch between them when using the laser or why you’d want to.

After doing the research to purchase my fiber laser I do know the Cloudray internal control is not currently capable of operating under Lightburn at this time. I did purchase my laser direct for Hoatian Laser in China I opted-for the all in one case style for space saving. The process was amazing easy and the shipping to my door form China was 3 days.

I have talked to there technical support and found them to be very attentive. Just one final note if you think you might need to purchase additional lenses for the laser it is best to do it withe the original purchase.They will do the correction file for you and make life much smoother.

Seems like they’d lower the price a bit and just let you choose which one you wanted…

@Rooster1956 the ones I’ve been looking at on the cloudray site have the Lightburn logo and state it’s supported…

What does this mean?

![]()

Two control boards are found on machines that have both CO2 as well as fiber. Trotec has a system called the FLEXX

Get more information here Speedy flexx: One laser system - two laser sources | Tips Trotec Laser

Thought about this unit?

It’s is ‘large’… It also is not a galvo head type, so the speeds will be limited to the axes speeds… similar to a ‘normal’ laser…

![]()

This is just a galvo fiber laser. One of the boards is lightburn compatible the other is not.

Why would they ship two different controllers?

![]()

Looks like it just like the Boss CO2 laser set up I have.

I like the larger format.

I could get a good size gun into this to engrave.

This would be a good question for the owner/inventor of @LightBurn

Love mine. Had a issue they quickly resolved

I have 60w co2 and a 20w fiber both om

Enlighten us on what the lasers ‘innards’ are?

This is what most of us are having a hard time selecting.

Assume OMTech from the text.

![]()