The essential “innards” in all fiber lasers are, power supplies (three of them) the laser source (usually a Raycus, JPT, Max or IPG and the control card. All of these items (and other parts, tower, base, galvo head, lens etc.) can be bought individually from different suppliers/manufacturers and assembled by anyone savvy enough to do so but it would be costlier than buying the whole assembled unit from a company who buys all the various parts in bulk to then put together.

I know these names… what did you decide on?

Why did you pick that particular configuration and would you change any of the components now that you have used it?

![]()

I have a Boss 1420 CO2 and wanting to move into a 2nd laser for engraving metal. I like the large format as I would like to engrave some of my rifles.

This is the first fiber laser I have seen with this large of a format.

A Texas gun collector I met always wanted his gun out in front of the house engraved with a message … When I think of a ‘good size’ gun, I think of him and his 2, 105mm Howitzers… that’s a good sized gun… ![]()

![]()

When I decided I was going to buy a fiber laser I knew nothing at all about them, the different laser sources lens etc. I joined a few different FB fiber laser groups and contacted four different manufacturers that I noted mention of on the groups. Most were trying to sell Raycus based machines (the Raycus or Max laser sources are cheaper but not as good as a JPT or IPG source. A large size engraving area using a 300 mm lens sounded good until one manufacturer gave me all the facts about the different lens and their capabilities. The supplier also gave me the low down on the different laser sources and steered me towards a JPT source and I’m very glad of that (it only cost a couple of hundred more dollars) The supplier also gave me a deal on three included lenses, a 70, 200 and 300. I’ve since bought another, a 150. I could really only afford a 30 W machine at the time which is great but I do wish I could have afforded a 50 or 60 W unit.

All of Alex’s videos on his Laser Everything channel on Fiber lasers are well worth watching.

Thanks for the review of your path to a fiber… I can’t really afford one, but I the boss is looking at our tax returns and maybe I can swing one.

Since I do more expierementing than actual work, I’d like to have as many options available as possible…

Which control board?

![]()

The BJJCZ board is the standard in all the Fiber Lasers I looked into. It runs with the EZCad software most of them comes with and also works with Lightburn by swapping the driver for the control card.

Was wondering if you saw my first post (#2) that shows a cloudray advertisement for a fiber…

As you can see it comes with two control boards… ?

Any clue as to what they mean?

![]()

Someone else up above in this topic suggested that was meant for a particular type of laser that combined both a Fiber and a CO2. Otherwise I can’t see a use for two different boards. As I mentioned the BJJCZ board is the common one you’ll find in all the usual Fiber machines.

Maybe it’s that they will supply which ever board you wish… Seems costly to give you two controllers when you will only use one.

Might be the way it was worded and translated…

Thanks again.

![]()

Barch Laser here said the downside to the MOPA is lower processing speed compared to an ordinary fiber laser. But I don’t see how that could be, if you have 60W vs 60W and this is the same 1064nm wavelength, why would it be different?

Or are they saying if you walk in with a $7K budget, the MOPA will be slower because you’re not buying as much wattage with $7K? That would be an odd way of saying it.

I know the MOPA coloring of stainless is a very slow process, but he doesn’t seem to be limiting that claim to just that specific process. He seems to be saying 60W of MOPA processes normal jobs slower than a normal 60W fiber laser.

@Dannym I think the guy in the video just wants to “pimp” his lower end models and is doing his best at being a wordsmith to market that lower more affordable line. Their company sells MOPA as well.

Food for thought: Why would they talk down any product in their catalog over another? This tactic reminds me of the car salesman that has many higher end models on the showroom floor but gets a better commission from the dealership when he sells the white 4 cylinder car vs the red 8 cylinder with the shiny chrome rims.

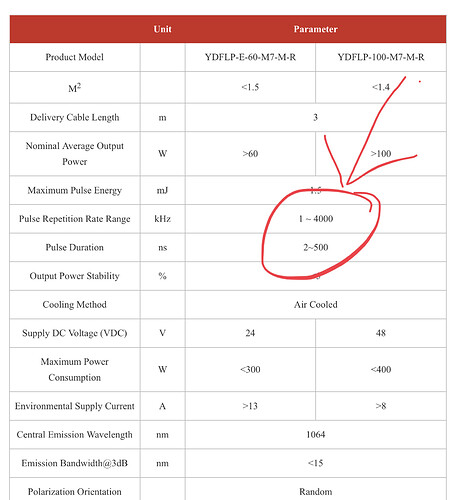

When we talk about FIBER LASERS, we must keep in mind three macroscopic measurement parameters:* Frequency (or rather the number of pulses in relation to a length of time) → kHz

- Power → W

- Speed → mm/s (or px/s)

Laser pulses are usually fixed: with standard fiber lasers, a pulse has a duration of about 120 ns, while the pulse frequency varies from 20 to 100 kHz.

Instead, with MOPA lasers, pulse duration varies and can be set in a range from 4 to 200 ns, with a frequency ranging from 20 kHz to 1 MHz. The short pulse is especially useful for marking on plastics, as it prevents burning the material by avoiding direct contact.

I suggest that you invest in the machine that best fits within the requirements of what you are trying to produce. If you do not think you will be marking plastics or stainless steel and titanium for color then definitely save your money and invest in a non MOPA.

That being said the ability to be able to have a wider frequency absolutely has its benefits.

Cheers ![]()

Sas

Right, but let me clarify- are you proposing that a 60W MOPA is going to be as fast, or faster, than a 60W fiber laser on regular jobs (not stainless coloring)?

I would think that, if anything, MOPA could be faster with the same average power could go faster with some of the new pulse options it opens up If it turns out fiber lasers already worked on a fixed pulse width that is actually ideal for a job, then at the least MOPA should be equally capable of delivering that same pulse width at the same average wattage. Because it only offers additional options, I don’t see any new limitations.

Now he uses the term fiber laser and MOPA as mutually exclusive terms. But correct me if I’m wrong, MOPA is still a fiber laser, and the same 1064 nm, correct? We just don’t commonly clarify “the non-MOPA fiber laser” And is Q-switched is a third type of fiber laser, but not all of the non-MOPA fiber lasers are Q-switched fiber lasers, correct?

Even with the same power, wavelength, beam polarization, min beam diameter, and mode quality parameters are additional beam parameters that could change its capabilities, but I have no indication that MOPA is different in these regards.

What I DO see is that normal fiber lasers at 20-100KHz, and MOPA is 20KHz-1MHz, there IS the 20KHz-19.999KHz range normal fiber can do but MOPA cannot. Is this low-freq operation used in normal jobs? If so that would explain why MOPA of the same power might have different capabilities

BTW, this is for a makerspace, so we cannot target a particular task to select the hardware for. It’s very hard to even select a work area size because we can only guess at what people need the most. Now, in many cases, the simple answer is typically “bigger is better” when there’s still enough floor space, but as I understand it, in this case bigger work areas come with larger focal spot sizes, is that correct? This does complicate the selection when it’s a tradeoff other than cost.

Haven’t run across this term?

![]()

The guy in the video is right if you were to compare a MOPA color “burn” vs Q-Switch non color burn. However when the lasers perform non color the MOPA engraves the same as a standard fiber in no color it is equally as fast.

Here is some more information to help with you decision making:

The Good and Bad of MOPA Fiber Laser Technology

The major advantage of using a MOPA laser is its ability to mark colors by surface oxidation and its adjustable pulse duration.

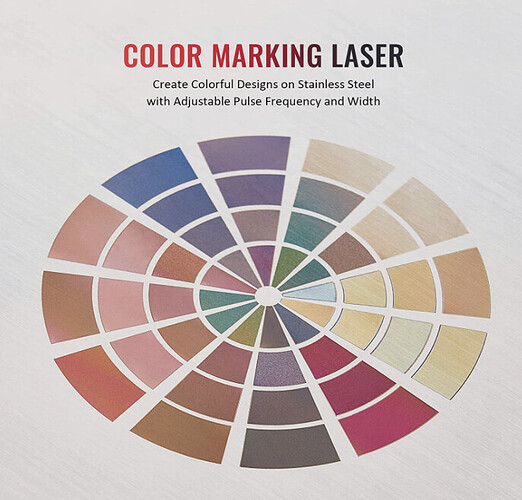

These images below can be engraved directly on to stainless steel without any special sprays like a CerMark using a MOPA laser but can not be done with a non MOPA. The true black on aluminum and stainless is a big deal. Also note the color engraving on the tumblers and pistol slide.

Since the frequencies, pulse durations, and energy are adjustable in a MOPA laser, you will have much more control over the engravings.

MOPA also lags in the speed of engraving. The color engraving part is slower than the average speed of common fiber laser engravers.

This will be a problem if you plan to process thousands of metal pieces with color engraved logos in a single day.

Short duration is especially beneficial when marking on plastic materials as it provides high contrast making with low or no burns and low foaming.

The low heat development in metal parts while engraving with MOPA lasers limits corrosion and gives clean marks.

MOPA fiber laser technology also has all the advantages of a standard fiber laser.

It has high precision, low energy utilization, powerful beam quality, high-speed marking, long lifetime, is air-cooled, high optical quality, and is maintenance-free.

The major disadvantage of MOPA fiber laser technology is its high price They are costlier than most other fiber laser engravers in the market.

MOPA v/s Q-switched Technology

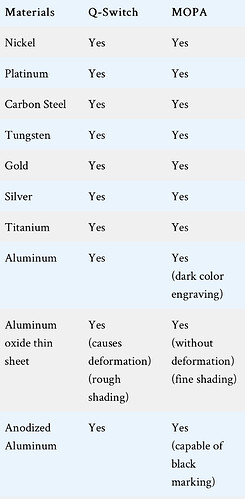

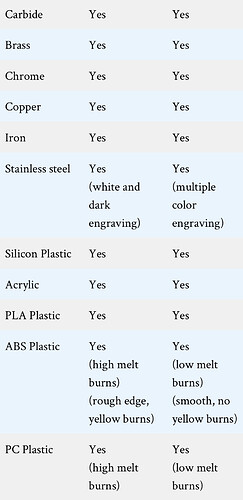

Though Q-switched and MOPA technology uses fiber lasers, their operation has fundamental differences.

Q-switching technology is sometimes referred to as “giant pulse formation” or “Q-spoiling”.

Q-switched technology is used on most standard fiber lasers to produce a pulsed laser beam. It allows the laser to achieve more extreme peak powers than continuous-wave lasers.

In a Q-switched laser, such peak power is achieved by using a variable attenuator inside the laser’s optical resonator.

In a Q-switched fiber laser, the pulse duration is fixed, and It can be anywhere between 80ns - 120ns.

MOPA technology uses two gas discharge chambers (i.e., the master oscillator and the optical amplifier) to control the pulse duration, and it is adjustable anywhere between 2ns - 500ns.

Also, Q-switching has a frequency range between 20kHz - 80kHz whereas MOPA can have a frequency range of 1.6 kHz - 1000 kHz.

Both these laser technology can process the same materials, but MOPA has a little advantage in processing aluminum, plastics, and stainless steel materials.

Is the difference only in the color engraving?

One of the major advantages of using a MOPA laser system is its ability to color engrave on stainless steel, but this alone is not the difference between a Q-switching and MOPA.

Q-switch technology is most known as fiber laser engraving technology. It is the default configuration used in standard fiber laser engravers.

Though both these techniques look similar, it works differently inside the machine.

Q-switching only allows the power supplies to generate path light between 1 - 500kHz, but in MOPA technology, it can generate 1 - 2700kHz or more.

This large amplitude enables MOPA lasers to have different engraving results over plastic and metal materials.

Both are split-type machine, so the laser source and the engraving head come as separate modules. ( @jkwilborn you had this question earlier in the thread on why it’s called split)

They look like this:

Also large cabinet type fiber lasers are also called split for the same reason:

Cheers ![]()

Sas

I have a 50w MOPA from lasersonly.com

In the research I conducted (much like a lot other posts here) a lot of the innards are the same.

I went with them as they are US based (but get their product from China) provided US support, provided free and quick shipping (their inventory is kept on hand in Jersey).

I have no complaints… this is just a hobby for me and your mileage may vary.

This is more important than anyone can ever imagine. We bought a double head laser(Industrial size) CO2 from China. Next time we will hire an agent in China to handle all the Chinglish communication in China. Even with that component we will not have a piece of mind.

We took out top insurance when we bought the laser for transportation. Laser got damaged in transport from China to Pacific Northwest. Contacted Insurance. After they lowballed us and went round and around we finally got a check after 2 years yup you read that right 2 years.

We won in the end but what a nightmare. All this was happening during the COVID19 lockdowns.

Buy American ![]() or at least from someone who has US stock.

or at least from someone who has US stock.

Cheers ![]()