Hello everyone. How do you like this engraving? It’s really cool that Lightburn can handle heavy layouts, with lots of vectors.

Those look awesome! Could you share a bit about your workflow or how you dial in etches like that?

It’s not easy. But the short recipe is as follows:

- a lot of free time

- the ability to work in Illustrator or CorelDRAW.

- Understanding the physics of the color engraving process. There are a lot of nuances.

- A lot of tests on metal. Looks at a 20 liter container piled high with unsuccessful blanks

Hi Aleksandr

I am so happy I discovered laser etch/cutting & LB forum because I get to see all this creativity, well done you and everyone.

Where can I read about the physics of the color engraving to understand it better?

What would you call this style of graphics, it is very effective.

Is it ok to reproduce once you have the settings…or is every attempt a possible candidate for the 20L bucket.

Even if he shares his settings, you most probably won’t be able to recreate them without a lot of testing. There are so many factors playing a role here, starting with materials and environment temperatures up to the laser source itself. You might take the workflow / image preparation, but to get the actual look, there is no chance to just reproduce.

Thank’s Misken. I was actually asking with reference to his own workflow…asking for settings is a bit pointless for me until I press the purchase button.

Waiting to hear back from a LM3 with a 20w & 1.6w with 40L assist.

Hi Peter!

Melvin is 120% right. Color engraving on any metal is heating the surface to a certain temperature. In our case, it should be 100% controlled and predictable.

This is influenced by a lot of factors, in short: calibration of the lens position (it should be as parallel as possible to the engraving plane, any deviation will give an uncontrolled gradient), power, speed, frequency, Q pulse, distance between lines, metal alloy composition, metal surface texture, heat dissipation from the workpiece at the time of engraving, air temperature in indoors (no joke, some colors are very moody, require conditions).

In addition, indeed all laser sources have their own rated power. I have 4 engravers on jpt m7 30w, all of them have different power ±10%. Accordingly, all settings are adjusted.

And another important point is the order of application of colors. Demanding, moody colors come first, then less demanding ones. The black color is always at the end, in fact it is not the color of running, but the burning of the top layer of metal. This requires very slow speeds, which in turn affects the heating of the workpiece. Therefore, the black color is at the end of the queue.

I hope it helped)

Thanks

Q pulse? haven’t come across that term yet…will look it up. I also get the color order due to heat. I roast coffee so there are many ways I can compare the process effect, and a lifetime of being around forges and toolmaker friends etc…just always paying attention to these industries but not being in them.

To reiterate, I am wondering how your particular settings and environment…on the day, perform in consistancy…would the 20L bucket of “almost’s got it!” weigh more than the “Wow thats great” .

Wondering if/how, a gas environment would change things…got to run! walk the dog time.

Thanks!

Just had a look at Q pulse on Wikipedia and followed the associated links. I have formed a mental picture analogy and want to ask if it seems correct.

If a laser beam pulses for a defined period and maintains full power/energy for that period it has a High Q.

If the beam pulses for the same time period, but power reduces at half the time period fron 100% power/energy to 0% by the end of the time period, The second half of the time period is Low Q.

Sounds like you are using a diode laser. Aleksandr uses a fiber laser, which is a total different class of laser (and even different LightBurn edition). That’s why you didn’t come across Q pulse, in diode lasers, you effectively don’t have that.

Just wanted to add that these results are the most beautiful results I have ever seen in metal etching. Awesome!

Yes Misken, I am going to begin with the diode, I will delve deeper into the subject. I have of course come across quite a bit of info during this three month+/- “it’s been arduous” learning curve, but worth it by the end…of the beginning.

Just wanted to say thanks for writing your wiki, its been very helpful…and a little intimidating for a tech-dummy, I last read your info on upgrading motors.

Getting back to the topic of this thread which is of course the marvellous creations above by Aleksandr and the aspiration to “attempting” to move in that direction. Would the user of diode be better using a 1.6w or a IR1064 for detail and would the coloration be repeatable on some level “given environmental+settings+materials were suitable”.

If you would like to contribute your knowledge in this area we would be very eager to learn, and ideally provide that knowledge to all, perhaps in our documentation. I’ve send you a private message to discuss

I have the most difficult projects related to the Russian Orthodox Church. Here, for example, is a small token measuring 50x28mm and an Orthodox icon 300x300 mm. Laser cutting is used here for frames.

Most serious projects have a huge number of points in vectors. Most engraving software is not designed for this. Lightburn handles this easily. That’s cool.

May I ask “what are points in vectors”?

It must be or should I say… is itdifficult to maintain correct temperature for colour correctness and consistency across the 300x300 piece.

On the bottom picture, what diameter are the blue circles? this is so effective when viewing…not zoomed in. I think it works like dpi/line space optimization so the human brain puts it together as a most pleasing image.

Thanks for putting them up here to see.

Normal diode lasers and co2 lasers are continuous wave (cw) mode lasers. The others are pulse lasers. The transfer is usually computed/adjusted using pulses/mm or at least that’s how I do it … maybe that’s my problem ![]()

A Q-switched laser changes the Q of the resonator to allow power stored within the fiber to drain. Longer pulse more power drains out… The Q-switch has a limited range of adjustment compared to that of a MOPA type. This make MOPA types the premier choice for the greatest variance in work types/materials.

Q-pulse (length of pulse) — Q-switch (output Q factor) … don’t confuse them… A circuits Q is often referred to in electronic computations for comparisons.

Q-pulse is the duration the fiber is allowed to drain, some lasers control this pulse via a Q-switch output. Fiber lasers pump up the fiber, which is also the gain material, then they are allowed to drain, trigger diode or q-switched, as long as the end is open, so to speak, it will allow the energy to exit … So virtually all pulses start at maximum power.

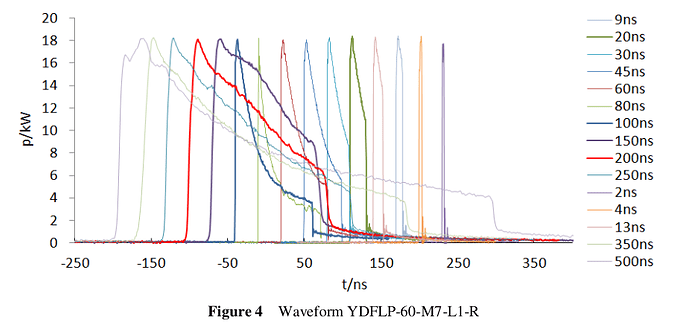

My 60W fiber has an output of 18kW during a pulse… This is from the JPT M7 MOPA source manual.

It’s difficult with these and even more so with a lower powered diode to maintain a similar temperature. Gantry types take even longer to transverse the axes.

Galvos are fast, will go 4m/s, but sometimes the same settings to get a single color used on a larger object doesn’t produce the same effect. The metal conducts heat very fast, if it takes longer to return on a scan, the temperatures won’t be the same as a smaller object.

Stainless steel and Titanium are the best at producing color oxides. My kitchen knives have our initials on them with the fiber.

@Deepspace have to agree, this is the best color job I’ve seen ![]()

![]()

Very interesting Jack. diode-gantry comparison helped a lot. Took a while to build a mental model. I will read further on what happens at oscillator and before.

Possibly dumb question!..but what happens to the energy packet after Q switching, between switch and targrt. Does it dicipate to eather or splash the target area with some mesurable value or none.