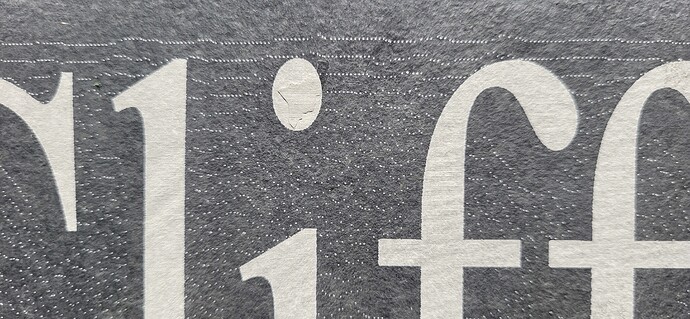

I am getting these multiple dots on any job, I have changed nothing and worked perfectly before any ideas would be great

If so, then it’s a hardware problem, most likely the HV power supply for the laser tube.

The rest of the pattern looks fine, so it’s likely a severe case of the Random Dot problem caused by the power supply allowing the tube to fire when the L input should force it off.

There are, to the best of my knowledge, no simple diagnostic tests proving that conclusion (other than the random dots themselves), so you may as well order a HV power supply and see if it improves the situation.

Thanks for the help I was thinking that could be the problem I had the same issue years ago with another machine, this one is a Boxford which is only 18 months old. I did the same jobs today that had the dots yesterday, one was ok the other the same dotty. If it was the power supply do you think it would have the issue on every job or could be random.

I’m sure the physics is not truly random, as the glitches surely depend on the tube current & temperature during the job, the power supply’s temperature, and maybe the time of day. Close enough to being random to suit me, though.

I saw those speckles in a machine maybe half a year old, then had the same thing happen with a replacement power supply. Some folks report a new supply cures all ills, others not so much.

Anecdotally, high-end (pronounced “spendy”) machines tend to have no random speckles, which suggests two different power supply designs out there. I now have three power supplies (one dead, one spare) sporting three different labels outside and identical circuitry inside, so I’m obviously not buying high-end gear. ![]()

Not much in the way of reassurance, but that’s about all I know.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.