I would like to upgrade my laser tube to either 80 watt or 100 watt. I can see that the increased tube length will require extending the side panel to accommodate, plus new power supply. I have a Vevor 50watt blue CO2, and would quite like to keep the same footprint in my limited floor space.

Has anyone undertaken this kind of upgrade?

Thanks for any help

The increase from 50W laser tube to 100W requires the replacement of laser power supply and water cooler

Thanks for the reply, I have the water covered with an external chiller. Was really asking if anyone had done this and could advise the outcome success. I suppose the other thing to consider is the diameter of the larger tube to 80mm if the mirrors will have enough adjustment in height

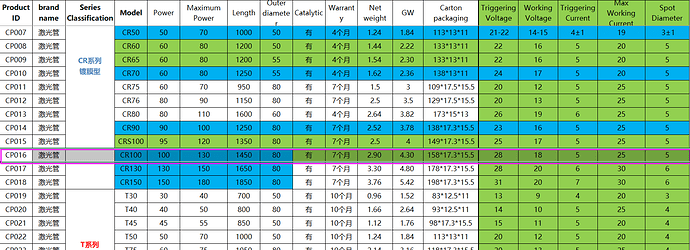

Keep in mind that even though you are aware of the extra tube length, I’d like to point out a few numbers.

My tube is 880mm (44watts), a ‘China Blue’, which is just barely over 1m in width. If you put a 1450mm tube in there, it will hang out over, 50% longer than the box is wide, conservatively. As m1 is not against the chassis and the tube is even further away, increasing the overhang.

Meaning if you want the same footprint you need something like Dr Who’s Tardis that’s bigger on the inside.

Where are you going to get an ‘extension’ cover for that tube?

Couldn’t find one anywhere and was advised that they are a ‘diy’ object. All of them I found on the internet were diy. Seems like they should be common, but no one mentions it until you go looking for one…

Let us know if you find a source.

I ended up 3d printing mine, but it’s hardly of the required size you’d need.

Also check to see if an 80mm diameter tube will fit in your machine and keep alignment with the mirrors. I can’t see how it could. Mine is a 50mm tube as is probably yours.

You will have to lower the tube by the half the difference to match the beam path of the 50 watt tube. Can you lower your tube mount 15mm to accommodate this? Even the 80 watt tube is 60mm in diameter, meaning a change of 5mm in beam height.

The other option might be raising the mirrors (beam path) but the non z adjustable head would probably nullify this. A combination of these…?

Might need to upgrade the whole optical chain if there is a height issue. There are probably other issues, I’ve not thought of. This is a major physical change in the machine.

A simple question may be why do you want to do this? I have found with my 44 watts I can do most of what I wish to do and even better engraving with an ability to use a lower power. You lose that ‘bottom end’ when you increase the power. My 10% power is 5 watts (assuming 50 watts), sometimes more than I need. A 100 watt tube is 10 watts at 10% power. Most tubes don’t lase too far below 10% power level. What do you like to do?

Good luck

I have wanted a larger tube ever since I received this machine. If nothing else the life expectancy is double. I found this on thingiverse. It’s a 80mm tube holder. It measures 18mm from bottom to bottom of tube when at the lowest setting. It does take 12 hours each to print.

How far is the bottom of your tube to the frame… i.e. is that enough to make up the difference?

Thanks Jack, I think you have made the perfect case not to go too far with this.

I have seen upgrades where the laser tube extends for another 500 mm, and I have space to do this without increasing the floor footprint. I really want to be able to cut 10mm ply (which 50 watts will do, albeit not too well). I thought the optical chain may be an issue as my tube sits pretty well onto the chassis, and I don’t think there is potential to raise the mirrors 15mm. Nice to have clarity and someone else’s thoughts too.

Thanks once again

With most of the stock heads, you can’t raise the head. That’s one of the issues with beam alignment is the head really needs a Z adjustment. I realized that pretty fast. I no longer have the stock head.

![]()

If I measured correctly 3/4" is the max height the bottom of the tube can be for the 80mm.

I would look at different lenses. The 4" is supposed to be good for cutting.

Life is confusing enough… ![]()

I don’t know where your mirror is. That would be the beam path and where you would want to align the tube to keep it as close as possible to the original path.

My only adjustability in the Z direction is tube holder modification, shims under the mirrors or the Z on the head. It would have to be pretty close.

When I was fiddling with mine, I was advised the the ‘same’ model, different manufacturer, can vary by 10mm internally…

![]()

Yea I need to get the bottom of the 80mm tube lower than 18mm for the output to be the same as my 55mm tube.

No perspiration, glad I could help you ‘clear your mind’ ![]()

I guess I have a different definition of footprint.

Didn’t think making a 3’ table designed as a cone and saying it’s got footprint of a couple of inches, was a valid description of it’s footprint, always looked at it from the top down… But ok…

Modifications on these can get rather complicated quickly if you don’t watch out and try to foresee some of the issues. It’s difficult learning this stuff.

Working on mine, to replace the head…

I took the head apart, down to the bearing. Found I needed a spacer… put it all back and realigned it, designed the spacer, cut it. Took it all back apart put the spacer and new head into it… What a pain. When I did the ‘rack and pinion’ upgrade, I wised up and cut a few ‘extra’ spacers that paid off.

I don’t know what I would have done without external help…

Good luck, take care.

![]()

More than likely it is not possible. Length isnt the issue at all. The issue is you have 50mm tube mounts. The mounts for any other tube diameter are too large…too tall…too wide. I know…I put a 55 mm tube in my laser and had to cut a new set out of plexi. I bought two different tube mounts for larger tubes…the only two on the web and there is no possibility they fit…too tall…too wide.

I actually am having a friend cad design some for 55 mm and 60 mm tube retaining the exact same footprint and mounting holes and tube height. I will then use my 3D printer to print them out so I can go to a 60 mm tube diameter.

I have dug into this extensively for these small 50 mm tube lasers there isn’t enough room on the deck for a mount any larger

I think it is not a good idea to use such a large tube in your machine but that is not the thing,

The funny things with these mirrors is that you can adjust them and as long as you hit the first mirror in the centre and the outcoming beam is parallel with your frame you are good, even when many people seem to think the tube has to be , which is not the case.

I’m in the process of upgrading my 60 watt to a 100. I am having custom mounts being made from a local machine shop (the store bought will not work, I’ve tried several sets as well as a couple 3d printed ones) You absolutely have to change mounts and by my calculations will barely make it it will at all. Your only other option is to raise mirrors 1 and 2 as well as the head. This has been a costly upgrade, at least for me. Best of luck to you

Is it not possible to use two mirrors at opposite 45º angles to move the beam back down to the correct level while keeping the beam parallel?

Hi Mark

Same issues as I have come across thanks to the forum help . Have decided to find an 80 watt laser Red Dragon Lasers are looking favourite just now

Regards

Mick

Mike,

I upgraded my Redsail 700 from a 60w tube to a 90w tube some number of years ago and have always been happy with the results. I would recommend that you contact Marco at LightObject. He carries every thing that you will need, except for the cabinet extension. Back when I did my upgrade, I ordered everything from China and it took, in some cases, many weeks.

A few points:

- Your current tube is probably 50mm or 60mm in diameter. You will need new mounts that are 80mm for the bigger tube. Most 80 to 100w tubes are 80mm in diameter. 80mm mounts run about $28. You will need mounts that will let your new tube set a little lower in your case, so that you don’t have to move mirrors. Light Object has mounts that are adjustable from side to side and up and down. Make sure your case has at least enough room to move the new laser tube from side to side by 10mm.

- You can find 80w and 90w laser tubes that are 1250mm long. Most 100w tubes are longer, like about 1450mm. You may find that a 80w or 90w tube is a better choice.

- Check the Power Supply Unit (PSU). The space in some laser cabinets can be limited, so get a PSU that will fit and give you access to wiring and test button and status lights.

- A good air conditioning or heating shop should have the ability of making you a case extension. It is a simple thing to do if you have a bending brace and a little sheet metal.

- If your laser does not have a mA meter built in, have a multi-meter advailable to set your working mA setting of the laser tube. You don’t want to burn out your tube by driving it at to high a reading.

I have never been sorry for up-sizing my tube. Since I do mostly cutting I also went to a 2inch focal tube for cutting. I found this to be a pretty easy upgrade. Respect the voltages and good luck!

Hi Charles,

That is great information, thanks for taking the time to share. I think I have decided that 80 watts would be more practical for me than 100 watts. I now realise the trade offs between cutting and engraving, I do both. I will check Light Object to

Thanks for the info

Mick