- Shippenville, Pennsylvania

- Thunder Laser 35 - 100 watt purchased December 2019

- I’ve been using LB Since I’ve received my Laser.

- My wife & I own a sign shop, the laser will be used as part of the business.

- A good friend has a laser he uses in his awards business & I’ve played with his.

- We also own a 4’x8’ CNC Router

- We do not have a web based store & our website is currently down for construction.

-

Flagler County, Florida

-

CamFive CMA5136T dual head, dual 130watt tube

Chinese Blue and White 100watt 2x4foot bed

Chinese 80watt CO2 marking laser

4.8watt Jtech Diode on a shapeoko xxl -

Using Lightburn for approx 1yr now

-

Started as hobby, Now full time production

-

2yrs experience with laser machines

-

Shapeoko 3XXL and Multicam 1000 series cnc.

Also Flatbed UV printers. Currently in process of purchasing either a Vanguard or a Mimaki.

1 Charlotte NC

2 Bodor 2017

3. Just now looking at LightBurn and like what I see.

4.Hobby

5.3 years now

6. Had a Novakon CNC mill but sold it two years ago

7. N/A

Welcome to the forum!

- Columbus Ohio

- Eleksmaker a3 pro

- just started with Lightburn.

- Part time production

- None

- CNC paper cutter, sign making equipment

- not yet…just selling in person or facebook

- Waco, Texas

- Learned on my makerspace’s Trotec, bought a 45w Glowforge for home last year, 60w Thunder Nova 24 should be here in July

- Brand new to LightBurn (but holy hell is it amazing), prior to now all design is done through Inkscape

- Principle Use - keeping my wife’s Etsy shop up and running

- Experience - Enough to be confident, not enough to be competent

- Cameo vinyl cutter and 3D printers at the office

- Web Based Store - dearscoutco.com

Hi All.

I live in Downpatrick, Northern Ireland, same place they filmed lots of Game of Thrones episodes.

I currently have a K40 with C3d board and a home built 600x1200 machine I Built it during the pandemic as something to do during lockdown.

I started using Lightburn in February and just love the software.

I am trying to generate some income from my machine as my main job as a wedding photographer has vanished at the minute. Probably until well into next year.

I am selling mostly on ebay at the minute and going well I hope to open an online store soon to try and cut out the eBay fees

I have a camera in both my machines a mobius in the K40 and a Lightburn 8mp one in the bigger machine and use these nearly every day I find it super useful for squeezing every inch out of the material. This forum is great for tips and tricks and its nice that everyone is happy to share knowledge.

I’d love to take credit, but the way she gets her product photos is brilliant. She’s in a facebook group linking makers and photographers. Post an item, pick a few photographer volunteers that match your style, they get a free product in exchange for some nice product photography. It’s sort of a win-win, but I’m still really impressed with the quality we get in exchange for a few dollars in wood and shipping.

Nice concept.

Taking product photos is not my hobby… But could certainly do with a quick course here or there.

Mims, Florida

BossLaser HP-5598 purchased 2020

I’m in the process of OJT since the company I work for just got this setup.

I work for a plastics products manufacturer and this is definitely a full time job.

Personally, I’ve used lasers as a hobby before with other people owning the machines, but this is my first go-round with using it for professional production. I’ve been at this for about a week now.

We also run a Torq CNC, and we may be getting another laser in the future.

Yes, my company is on the web here http://www.marketingholders.com

Hello,

- Rossville, Georgia

- Orion 60 Watt, 20”x28” since June 2020

- Been using Lightburn for a week.

- Hobby/supplemental income

- I only have been using the laser one week.

- Have used AutoCad, Plc Programming and HMI programming Software, No CNC Type use though.

- No web based store yet, will add if I do.

So far I am enjoying LightBurn and just purchased a camera to use. Looking forward to setting that up.

I’'m in Haughton, Louisiana near Shreveport

My laser is a red and black KH-7050 upgraded from the factory overdriven 50 watt tube to a true 60 watt tube from Light Object after about 3 years of service on the original tube.

I’m pretty handy with RDWorks but added Lighrburn to my systwm a couple months ago when I upgraded my computer.

I use my laser as an enhancement to my woodworking and to add an extra service to my customers.

My laser is my only computer controlled piece of equipment at thia time but I am considering addi g a CNC router in the future.

So what do you think of the speed difference between RDW and Lightburn?

![]()

a warm welcome to all the new Lightburnner

I absolutely love it! SO much easier for me to program and create with it

I have not had a whole buch of luck with photos though. I have “Photograv” but it doesn’t swem to get along with Lightburn very well yet. Unfortunately (or maybe Fortunately) I’ve been too busy to really play with it for photos.

The trace and offset fetures are great! As is the ability to curve the text around objects.

I sometimes find myself wishing for an easy way tondraw and arch but that hasn’t been very often.

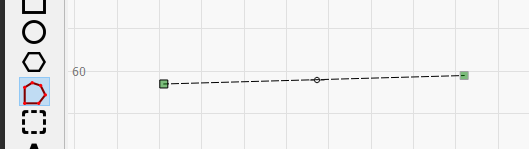

Draw a line, switch to Edit Nodes, grab the line and pull it:

It’s not a perfect arc, but it’s quick.

For using PhotoGrav images, make sure you set LightBurn’s image layer setting to ‘Pass Through’ so it doesn’t try to re-process the image for you.

Welcome to the group. You are only about 90 miles north of me, I am in Kennesw

- Location: Sebastopol, California

- Laser owned: Voccell DLS 50 - delivered May 2017. (Machine is due for an overhaul.)

- LightBurn Experience: I helped Lightburn get support for the Voccell working in Jan 2018, and I’ve been using LightBurn since.

- Principle Use: I use my laser for production, hobby and teaching. I teach Fusion 360 CAD and advanced laser cutting techniques.

- Amount of experience with laser: Before I had my own laser I spent a year using the 4x3 ft laser cutter at our local makerspace – Chimera Arts.

- Other computer controlled equipment: I’ve had a Taig desktop milling machine with a Flashcut CNC controller for about 15 years. Also I’ve been working on refurbishing a 4x4 CNC router at Chimera to make it more accessible for the general membership.

- Web Based Store: Microcarpentry.com Specific products are available on Etsy, Amazon and Amazon Handmade.

- My blog on laser cutting: https://microcarpentry.blogspot.com/

- Laser portfolio

Howdy Neighbor!

I’m in Guerneville.