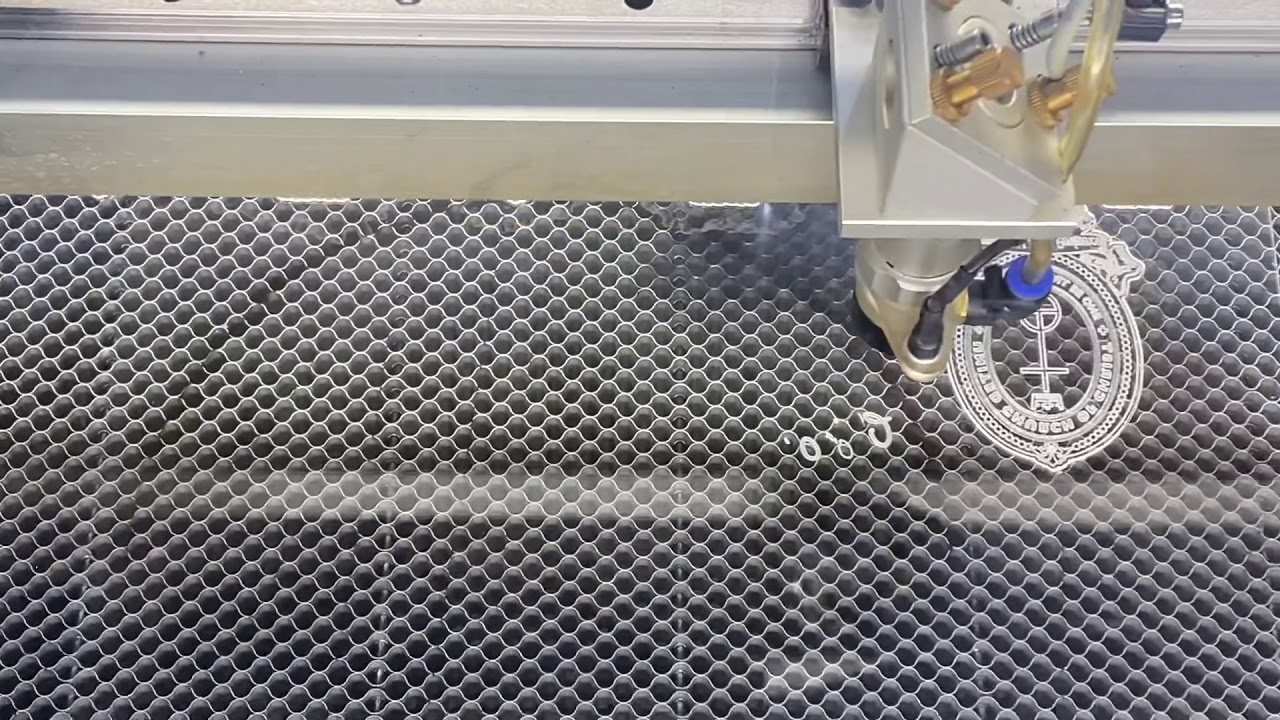

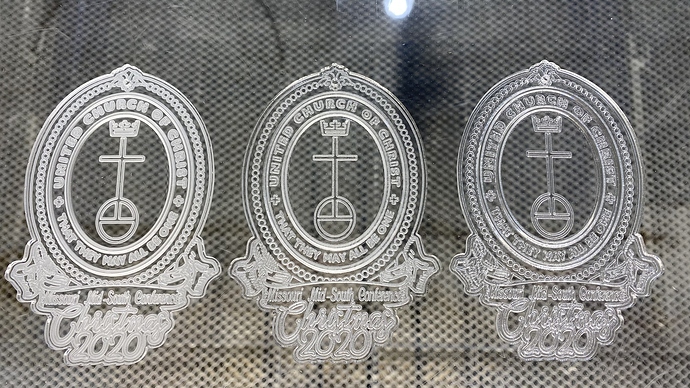

Faster process time, less wear on the machine, more predictable outcome when designing large quantity multi item runs. The flaming on the Out-Focused Z (when the two inner rings are being processed) is expected as I intentionally do not run air assist to prevent flaking. I made many test runs of this to dial in the precise speed and power for this wide line’s depth and preservation of the frosted look.

I’m running a modified lens holder with a 101mm lens in the lower mount of the tube to span the safe Z distance from the holder as a means to facilitate engraving without air assist and not risk lens contamination or fire from flare ups.

I tested this process with both extruded and cast acrylic. Surprisingly, in this process it was the extruded acrylic that allowed me to preserve the frosted look the best (while cast was transparent). Usually, I find this to be the opposite effect in fill layers.

This is a sealed laser enclosure with fresh air intake and aggressive fume extraction both from and to outdoor air.