Don’t take this wrong, but put yourself in our position.

Everyone tells us it’s aligned and focused, so we take that with a grain of salt… In actuality it’s usually something occurring in the alignment procedure and it is not aligned properly.

I trust you wouldn’t be here if you didn’t think you’ve done all you can…

We are assuming that you did in fact properly align it… however, as you can tell, most seem to think it’s a focus issue. To have a proper focus you have to have a proper beam from the lasers source, the tube in this case.

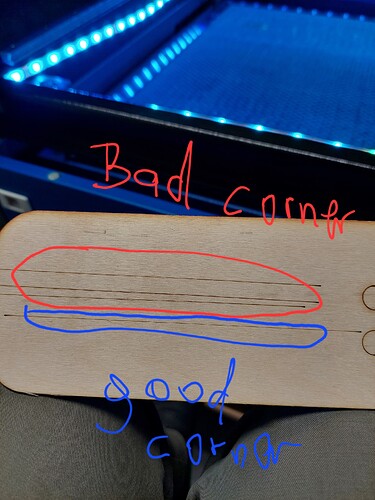

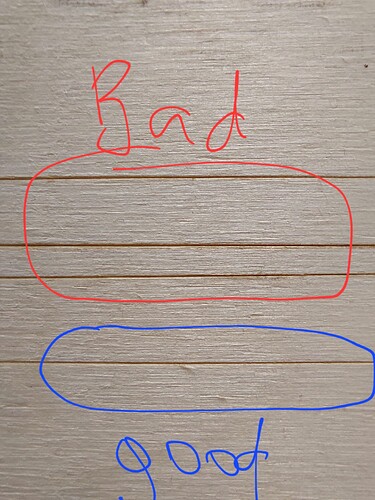

- unequal burn areas (corners)

- performance change, need more power for same job

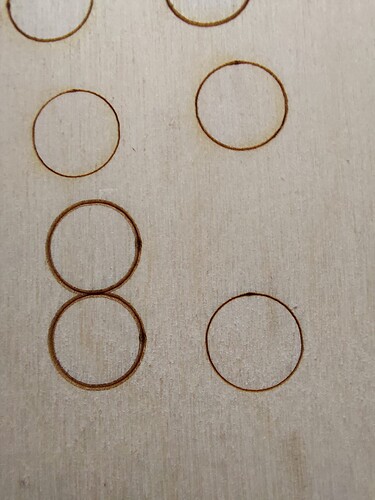

- variations in the tool line, looks like in/out of focus

- tool path and surrounding area varies in a small area…

a. you can see this in your circles

All of these are symptoms of a failing tube.

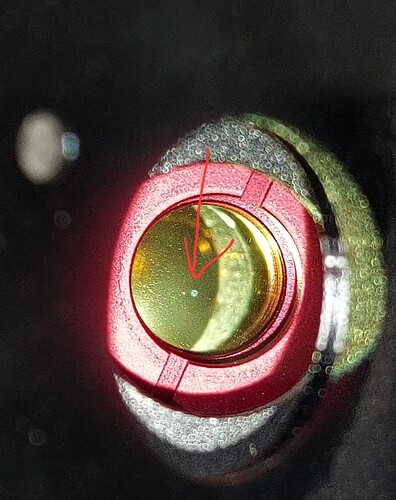

I’m also concerned over the size of your output beam, it’s smaller than I’ve ever seen.

Usually the higher the power the larger the beam.

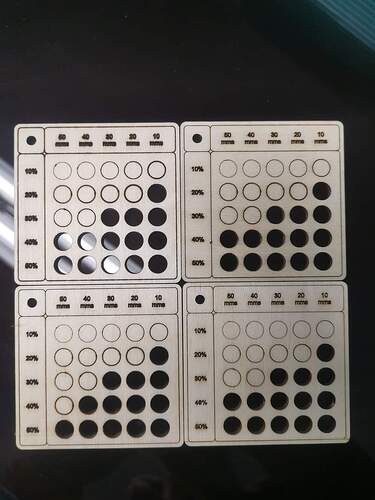

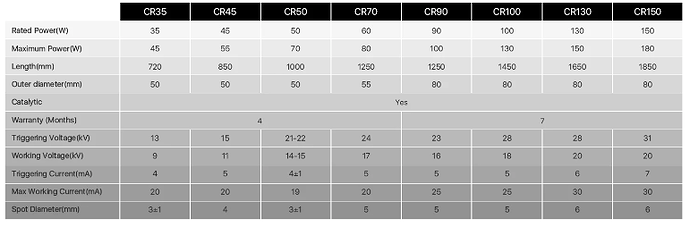

Pulled this chart off Cloud Ray for CR tubes… looks like it should be about 5mm… how big is yours?

I try not to use the term level, what should be used is square in all three dimensions. A cnc should operate the same, mounted on the wall as on level ground. Level just is a handy tool to use, but it can be deceiving.

So to be square, the mirror also have to be square within the 3d area. If you start with m1 off center, you have to follow it down the path… in fact m1 is the basis of the path the rest of the way so it should be centered. Don’t redesign it if it isn’t… there is some slack room, but the closer the better.

Also keep in mind that an 18mm mirror has an X axes size of around 12mm when viewed from the tube or lases beam. If it’s a 5mm beam then 12mm-5mm is 7mm/2 is leaving only 3.5mm each side and you’re off the mirror… somewhere around half the beam width…

Being off from the start means all the following mirrors have to be off that amount from a true 3d square.

The closer to the center of the mirror, the more room you have for error or to correct anomalies.

The only mirror that probably won’t be centered is m3. You have to catch the beam from m2 with the head (m3). Moving m3 along Z will move beam from left and right going down the lens tube through the lens to the work table. It’s much more important to be going down the center of the tube striking the center of the lens. If it hits the lens at an angle, your cut will be slanted as a result…

This is a good explanation of how to align a laser. It probably has adjustments that are not available to you, but the theory is great. You do have to put with some British humor…

Hang in there, I’m sure we can resolve this… It’s much more difficult remotely