I have used a lot of the different formulas for marking porcelain tiles. I don’t like the paint types because it’s difficult to get the paint off and leave the TiO2. There are a lot of mixtures available you can try. This is one of the TiO2 mixed with water and maybe a touch of glue. This thread has a few you can check out.

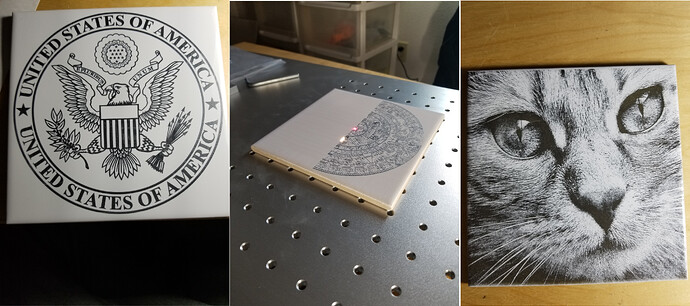

I believe these are all TiO2 coatings using this mixture from the above link.

The cat image has to be labeled on the back because I can’t tell it from the LBT100 spray that I usually use. LBT100 is consistent, usually produces good blacks, easily washes off with water, is non-toxic and is more expensive than the NTM methods with a lot less elbow grease.

This links shows some of Nicky’s tiles he’s done with paint.

Most of this fiddling around is done with MOPA machines that have more control over the pulse shape. If you have a non-mopa, check on what pulse size your source produces. Is this your the source pdf? The MOPA has a larger frequency range or more pulses/mm.

If I have the correct source, yours seems to produce a 80~110 ns pulse and you can vary the frequency from 45~60 kHz. You’re going to have to work with it.

When you first spoke about engraving, I though of this, again by Norton…

Looking at your tiles, I think you have an thickness issue as the results vary across the test piece. Usually when you fuse the TiO2, it shows up black. Make sure you use a paint that has the most TiO2 in it for the best results. Slow it down and advise on what frequency you used.

Ask if you have issues.

![]()