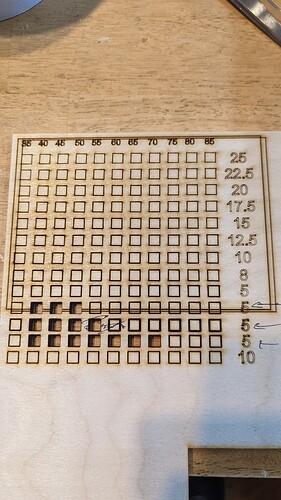

The power is not increasing as expected at settings above 45%

55w OMTech - less than 1 month of use. I am having trouble cutting through materials that I easily cut through before. Previously I could easily cut through 1/4 birch ply at 10mm/sec 50% power.

Also I’m having trouble cutting through black 3mm acrylic, though I easily could a week ago.

The stranger thing is that I can cut through the 1/4 ply at 5mm/sec at power ranges between 40% and 70%, but not above.

Here I show how easily I could cut below. Setting that worked easily for birch were 9-10mm/secon at 50% to 70% power. Acrylic cut at 17.5mm/sec with 45% power.

But now the Birch is cutting only at much slower speeds, and with strange power settings. I also tried adjusting the height of the z table slightly up or down from the standard focal distance.

Last night I was unable to cut through the 3mm black acrylic at any setting. Then today I tried cleaning the lense and mirrors. I was then able to cut thought the acrylic and thought the problem was solved. But when I try birch, I still am having issues.

I have been watching the digital ammeter on the power supply and it is responding as expected - i.e. the 85% is about 20ma and the lower percents are correspondingly lower ma.

I have a lot of questions that hours of forum reading have not quite been able to answer.

Can the digital ammeter on the power supply be relied on?

Do I need an analog ammeter to be able to test for tube issues? Are there step by step instructions for installation that anyone can point me to?

If the mirrors were out of alignment, how would I know and what would the effect be?

How do I know if my bucket of distilled water with pump is insufficient to cool my tube and if it is causing problems?

Could etching annodized aluminum at 45% power for many hours cause a problem due to reflection? Why/how and what can I do to resolve it?

Are tiny smokey specs (1mm or smaller) on the surface of mirrors and lense a problem? What causes them and how can I fix that? The do not clean off with 99% alcohol and cotton swabs.

Does anyone have a link to a step by step instruction for troubleshooting tube health issues? What and where can one buy a device for testing laser output power?

Thanks in advance for any help!

…

…