I hope I have posted this in the right place. I’m considering upgrading my diode laser from a 20w to 40w laser head. the 40w has a bean concentrator and is only 0.19mm compared to my 20w which is 0.3mm. Will this give me better deffinition IE DPI. The extra power is not important I’m more concerend with the image quality. Any advice would be appreciated.

What module and lens are you using now and which module are considering moving to?

The smaller focus dot will likely translate to more potential detail… however, that may not equate necessarily to higher quality engraving for various reasons. This will depend mostly on your specific needs. What medium you engrave to will have a big effect on this. What types of things do you engrave and onto what medium?

Take a look at this Topic for a case where an upgrade can be counter-productive:

Note that going to a higher power laser could also reduce the effective resolution of power available to you. Let’s say for example that your current laser gives you a good gradient from 20% to 80% on the medium you’re engraving to. That translates to S values of 200-800 or a 600 value resolution. Let’s say this gets reduced to 10% to 40% (100-400 = 300 values). You’ve reduced by half the granularity of effective power that you can use resulting in less dynamic engravings.

So long story short… this could improve detail depending on your needs but is not without potential tradeoffs.

First many thanks for your reply. I currently have the Atonstack A5 20w machine and was considering buying this. 40W 405nm Engraving Laser Module For A5 Laser Engraving Cutting Machine Eye gC | eBay They state the dot size is smaller and based on this should mean more dots per inch with out overlaping… I was hoping that this would give a better image on plywood which I currently use to etch pictures. I don’t understand how more power would result in a loss of quality. Surely if I use a lower percentage output the laser power would be similar to my 20w machine. What am I misunderstanding here?

Going to extremes will help illustrate this. Keep in mind that you’ll have the same number of total steps available to you irrespective of power level (S value 1000). Let’s say with a lower power laser you had 10 levels of power where you could get discrete variation of a burn. With a higher power laser let’s say you can only get 2 levels so that anything below is not burned enough and anything above is burned too much. Basically this would limit you to on or off as compared to the lower power laser where you could have more variability of power within the necessary range.

As an analogy, imagine trying to do fine engraving work with a small hammer and chisel. This combination would allow for a lot of control and variability. Now double the size of the hammer… It’s just a blunter instrument and will limit the fine variability.

Looks like you’re looking at 2 laser modules within the same family. Hopefully someone who already has both of these can comment on any differences in burn character.

I imagine running images on plywood you could see some additional detail with a finer focus dot, depending on the quality of the plywood. I imagine on rougher surfaces the limiting factor on detail would be the material, not the laser. If you have a very smooth surface it could make a difference. Wood is likely to be more forgiving focus variance between the two laser modules than something like anodized aluminum.

Thanks again for your explaination. I started out with an Ortur master one 15w and had great difficulty getting a good image on any wood. Since my purchase of the 20w Atomstack my work results have improved. I sand birch plywood then coat with bakeing powder solution. So far I have made good progress but being a retired photograher I’m aiming to improve even further. I’ll keep you posted if I upgrade and see worthwhile results.

I suspect the baking powder probably helps in improving detail.

If focus dot size is your primary goal for this I suggest you also take a look the Sculpfun S9 laser module. Depending on what part of their documentation that you look at they claim somewhere between 0.06 to 0.1 mm dot size or engraving line thickness. I don’t have direct experience with this laser so keep that in mind as well.

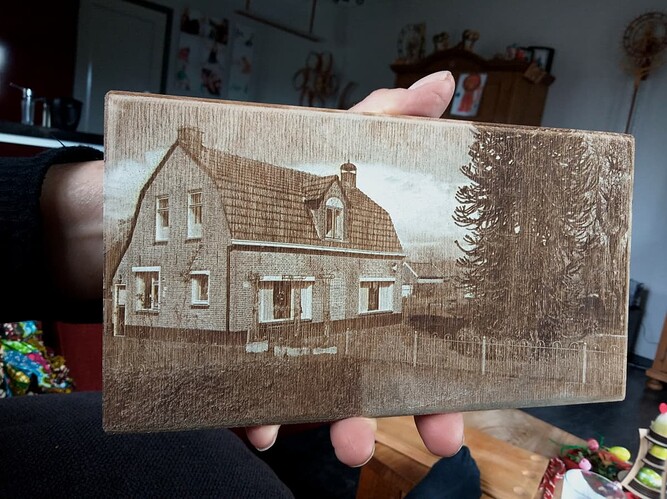

coincidentally lasered this house today with a sculpfun S9 on wood, I think it’s a nice result

nice greetings Sjaak

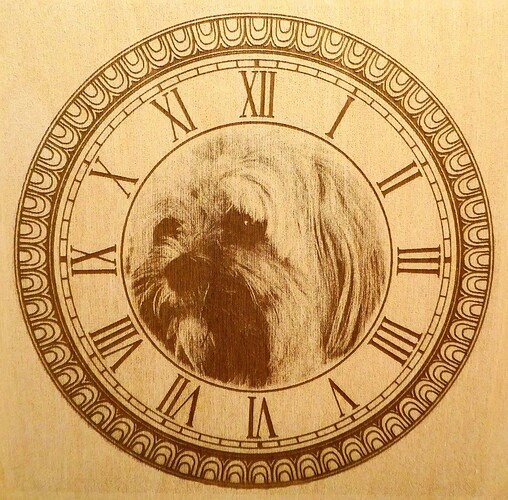

I make clocks with these.

Nice result. What settings did you use and what type of wood is it?

Hi Ronald I have just had this S9 module for 4 days, wood type is Russian birch plywood with the setting speed 30 mm sec. 40 power and 300 . dpi

Uploading: 20220410_173256t.jpg…

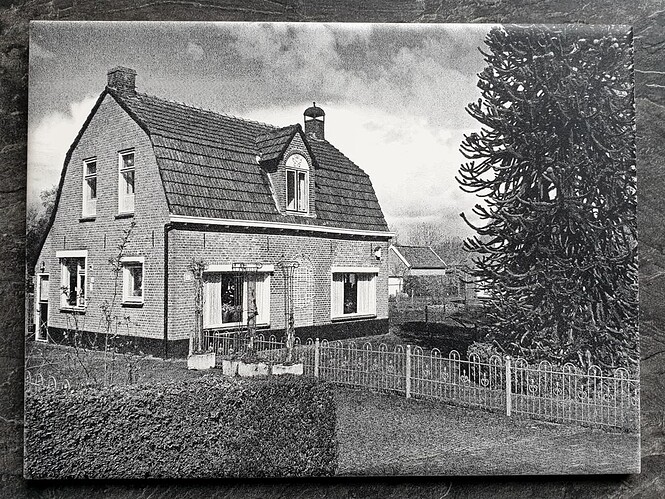

this was done with the Norton White Tile Method 20x15 cm speed 30 mm/sec power 70% and dpi of 300 with the sculpfun s9

greeting

That looks exceptionally good. I have never tried etching on a tile. Have many health issues plus I’m 84 so a bit slow on the uptake. ![]() I do a lot of woodturning so laser work is for cold days when I can’t get out to my workshop. You have tempted me to try that now. That sure has a lot of fine detail.

I do a lot of woodturning so laser work is for cold days when I can’t get out to my workshop. You have tempted me to try that now. That sure has a lot of fine detail.

Hello

Doing the upgrade will give you better definsion

And engraving abilities. I have laser tree 40 watt works very well. And mounted on the Ortur LM2 . I like the fact that i can boost the speed with this laser. Distance between the laser body and work area is 40 to 42 mm

Which is nice in case of flip up’s when i am cutting.

Will cut 3.mm ply in 2 pases at 150. All i can say is it does great job. I use air assist on all my work as well

to keep the lens clean. Hope this helps

Cheers

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.