X-Axis Angled Movement After Extension Kit Install - Replacement Idler Brackets Issue

Hi everyone,

I’m having alignment issues with my Laser Master 3 after installing the extension kit and need some help.

Background:

Background:

- Recently installed the extension kit on my LM3

- During installation, the original idler brackets broke

- Ortur sent replacement idler brackets and screws

The Problem:

The Problem:

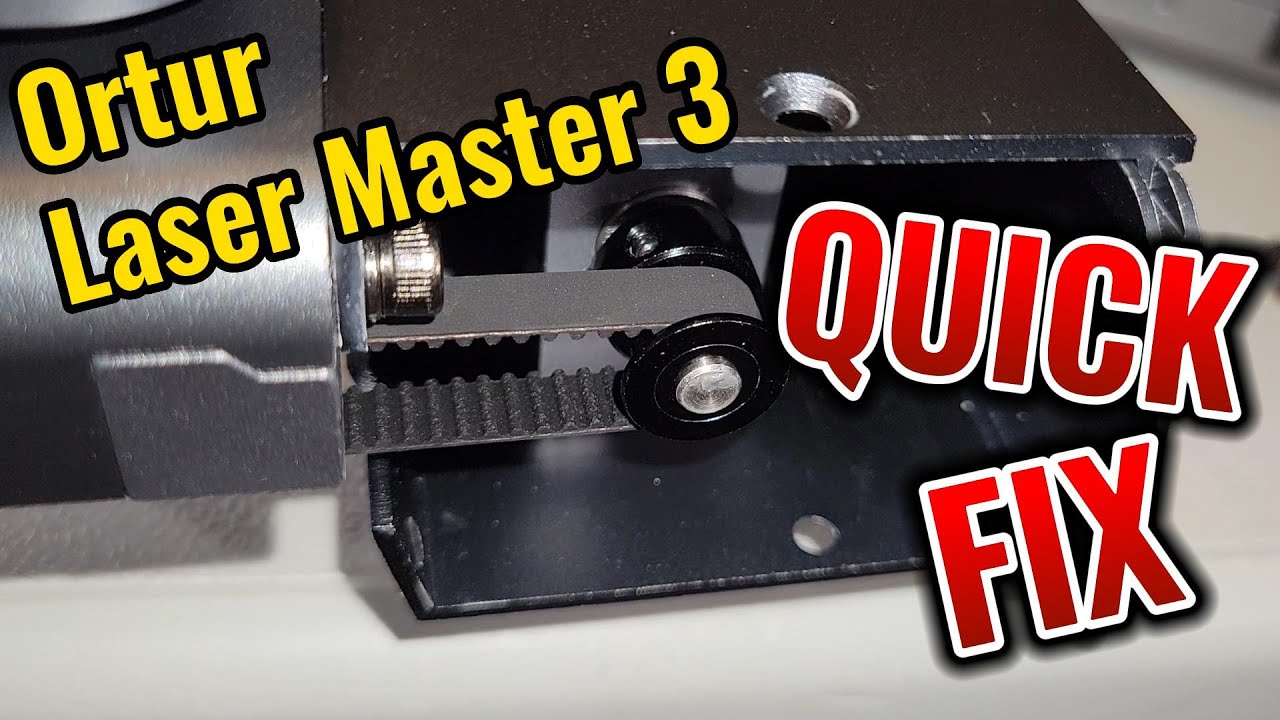

The replacement brackets are significantly different from the originals:

Old vs New Idler Brackets - Notice the size difference and missing tension markings

- Larger and longer than the original brackets

- Missing the tension marking indicators that were on the original brackets

- After installation, my X-axis no longer moves straight - it travels at a slight angle instead of true left-to-right movement

What I’ve Tried:

What I’ve Tried:

- Tensioned the belt to achieve a “guitar string” sound when plucked

- Moved X-axis fully down before installing belt in the slit

- Adjusted tension multiple times on the replacement brackets

- Ran test engravings at various speeds (200-2000)

Current Results:

Current Results:

The engraving quality has degraded significantly:

Text engraving test - Notice the inconsistent letter quality and alignment issues

Additional text test showing “wonky” letter formation

Circle engraving test - Circles aren’t perfectly round, showing the X-axis alignment issue

Issues I’m seeing:

- Text engravings come out inconsistent and “wonky”

- Lines don’t align properly

- Circles aren’t perfectly round

- Overall engraving quality has degraded significantly

My Question:

My Question:

Has anyone else experienced this issue with replacement idler brackets? The machine worked perfectly before the extension kit installation. Are there specific tension settings or installation tips for these newer bracket designs?

Key observations:

- The X-axis angle issue started immediately after installing the extension kit

- The replacement brackets have no tension reference markings

- Standard “guitar string” tension doesn’t seem to resolve the alignment problem

Any help would be greatly appreciated! ![]()

Machine: Ortur Laser Master 3 with Extension Kit

Software: LightBurn

Issue: X-axis angled movement causing engraving quality problems