I am trying to engrave this image, but the x axis seems to be moving, I’ve made sure that my material is stable and it keeps doing it. I looked into pwm rising edge valid, but when engraving a full square it does fine. Could this be an issue with the program? I’ll include a picture of what it is doing and what it should look like.

The axis movement looks fine, because the vertical lines are not broken.

Have you gone through the Scan Offset calibration sequence?

Do it for a range of speeds and it should line things up pretty neatly.

Ok I went through the video you linked and it was very helpful, I followed his process and adjusted until my square looked very good. I then went back to my original program and got some strange results, could this be something to do with my program? I’ll attach pictures.

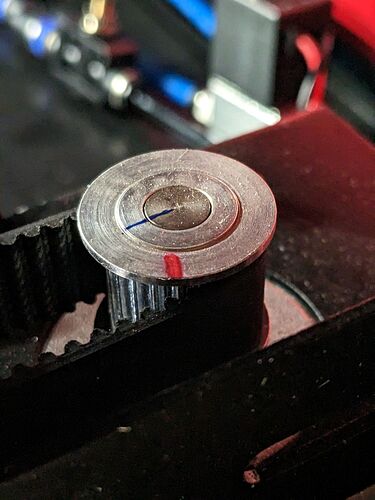

Assuming the displacement happens along the X axis, check the pulley attached to the motor shaft.

Almost certainly, the setscrew holding the pulley to the shaft is loose, allowing the pulley to rotate on the motor shaft. The setscrew should be tight against a flat on the shaft, but when it’s loose the shaft can turn a little bit one way or the other: it jams in one position until the motion works it loose, then it rotates and jams in the other position.

Tighten the setscrew in the middle of the flat and things should start working again.

A length discussion of a similar situation:

The pulley on that machine had a clamp, rather than a simple setscrew, but the solution is the same.

I found a pulley tensioner and tightened it as tight as it could go and I’m still getting strange results, could this be a program issue? It seems to happen at the same point each time.

That looks like a pressed-on pulley, in which case it has no setscrew. The advantage is that it’s unlikely to slip on the motor shaft, the disadvantage is being unable to just tighten a screw when it does.

The setscrew might be halfway down the pulley, hidden by the belt from anywhere you can put your eye. Use a mirror to see the far side of the pulley while you move the belt by hand (power off!): if you see splines all the way around, it’s a press-fit pulley just like the one on my OMTech red-n-black machine.

Draw a line across the motor shaft and the top of the pulley as a visual reference:

The next time an offset wrecks an engraving, slap the Emergency Power Off button to stop all motion immediately, then look at the pulley: if the line is no longer aligned, then the pulley has rotated on the shaft.

However, all that seems unlikely, because those pulleys are a really snug fit.

Another place to look: the laser head, because various bits & pieces can loosen without warning:

The screws holding the brackets at the laser head and on the idler pulley should be tight, because a loose bracket can shift in either direction as the head direction changes.

Give everything a serious shake and feel what wiggles when it shouldn’t…

There’s a distinction between “at the same point in the pattern” and “at the same point on the platform”. The former may indicate a settings problem, the latter suggests a mechanical issue.

If you move the pattern to a different place on the platform (upper left instead of dead center, for example), does the shift follow the pattern or stay with the platform?

Doing this sort of testing on cardboard will reduce the angst of wrecking good material. If changing the laser intensity to avoid torching the cardboard also changes the problem (at a fixed position on the platform), that’s another piece of debugging information.

The problem happens at the same time on the pattern not the platform, I’ve moved it all around and it always seems to stay the same, expect for when I changed the belt tension is shifted direction. I think it might still be belt tension but im not sure what is correct tension for these belts.

If the X axis drive was “losing steps” due to the motor stalling or the belt skipping on the motor pulley, the image could not return to the correct position again, because the controller does not know where the laser head is: there’s no feedback.

Engraving a pattern consists of repeated scans along the X axis following a very well-controlled sequence, with the head accelerating from a stop, crossing the engraving, decelerating to a stop, then accelerating again in the opposite direction, with no abrupt direction changes.

The image controls the laser beam power and doesn’t affect the motion: the scanning proceeds the same way at the same speed over light and dark areas of the image.

If the X axis acceleration (or speed) was too high for the motor to follow, then you’d see the typical “lost step” symptoms: an abrupt shift or several shifts that do not return to the proper alignment.

So what you’re seeing is a mechanical problem, rather than an image problem. That’s confirmed by having the symptoms change when you do something to the X axis belt.

The fact that the symptoms reverse definitely means there’s a mechanical thing in the X axis drive that gets stuck in one way or the other, depending on the forces applied to it, which is precisely what happens with a loose motor pulley. While you’re tweaking the tension, you’re also (inadvertently) moving whatever is loose to the other end of its playroom.

If you can feel that motion, you’ve found the culprit.

As far as the belt tension goes, I can move the X axis belt one finger’s width away from its neutral position at the middle of the platform with a “gentle” pull, about 1 pound on my tension gauge. Pulling with 2 pounds moves it half again as much and 3 pounds (a “firm” pull) doesn’t make much difference.

You could calibrate your finger by pushing on a kitchen scale, but you can probably feel the difference between “gentle” and “firm”. If the belt is more than two finger widths away from neutral with a “firm” pull, snug it up by a tooth.

So:

- Mark the motor shaft & pulley

- Mark the position of all the brackets

Wait for it to fail again, then look for any tracks of the monster!

Any suggestions of what might be loose? I’ve marked the pulley and checked all the bolts and they seem to be tight.

At this point, it’s a matter of waiting & watching.

I still think it’s the motor pulley, because that wraps it all up in one tidy lump. The other choice is a bracket holding a pulley that jams one way or the other depending on which way the belt is moving.

This could be one of those cases where all the visible screws are snug and nothing obvious can possibly move, while a piece of the machinery you can’t see or touch is ready to fall off.

I just stuck my head inside my laser and applied a hex key to all the screws I could find. Most were tight, but a few were … less snug … than the others: not enough to move, but obviously not tightened as well. The X axis gantry seems to be held to the Y axis slides by four screws on each end, one of which is barely visible inside the end caps, where checking it would require dismantling the gantry beam.

Ditto for the laser head, which seems to depend on two screws holding it to the linear slide; there may be more, but I can’t tell. Checking those requires taking the head off, which is just not happening here without lots more provocation.

Sheesh & similar remarks.

So, other than being far more meticulous than anybody should be, I can’t offer much. When you do find the loose thing, you gotta tell all of us!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.