Hi, I am fairly new to lasering. I have a 60w co2 Ruida machine which is only 6 months old. I have been having non stop issues with it slipping. I have checked the belts and pully and everything is perfect. I have spoken with the company where we purchased the machine, and they advised to do a test back on there software, which seemed to be fine. I re tested on lightburn and it slipped yet again. I am wasting granite material, which is costly as you can appreciate, and I am hoping someone can advise me what could be the issue I am experiencing. The template is a photo and text, do I have the correct settings of 400 speed for both or is this still too fast? Thank you

why not do your tests and tweaks on cardboard or plywood?

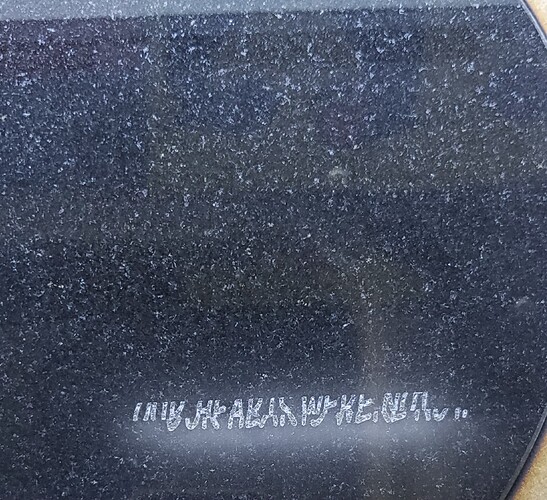

It’s not the best photo to see the problem, but from what I can see it’s the steps that are being skipped.

Hi, I do tests on ply etc and it is so random. It will work fine on one plaque, I then clean any debris off of the lense head and do the next one, and it slips again. I am engraving on granite and wondering if this is a common issue

It is a mechanical problem (most likely) and has nothing to do with the choice of material.

Troubleshooting can be tricky at times, I have read from people who have had a loose pin screw in one of the small pulleys.

It would be helpful to see the *lbrn2 file so we can look at the details.

If the text is done as a Line, rather than Fill, then 400 mm/s is likely much too high: the machine will be unable to reach that peak speed and may die trying.

With the power turned off and pushing slowly by hand, does the laser head move smoothly left-to-right and the gantry front-to-back? If you feel any roughness or obstruction or sudden looseness, particularly in the left-to-right direction, that may stall the motor. This seems unlikely, but is easy to check.

How do I share the file? The text is a fill

Drag-n-drop it on your reply or hit the Upload icon along the top row.

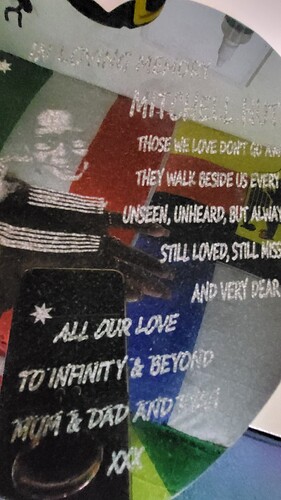

Millie Rose.lbrn2 (376.9 KB)

I hope I have done this right, I am very new to this and the forum. Thanks for being patient and trying to help

We have checked this and that all seems good.

Worked fine.

I don’t see anything out of the ordinary, but other folks who are more knowledgeable about how such things can go wrong can now take a look.

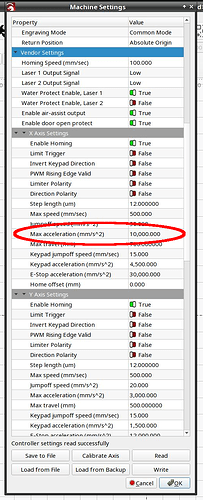

A deeper (and less common) problem can be the acceleration setting for the X axis, where the controller tries to change the head’s speed faster than the motor can handle.

In LightBurn, go to Edit → Machine Settings to get a display of all the controller’s configuration values. Click on the bottom line showing Vendor Settings, agree you won’t change anything, then take a look at the X Axis Settings to see the Max Acceleration value:

If that’s much higher than 10,000 it could be a problem. Don’t change it, just remember what it is, hit Cancel, and report back.

I don’t see any problem with the file.

I will try to reduce the speed a lot, even if it hurts a little, but this way you can rule out that the machine (can’t) handle it.

I can’t follow you completely with your min max power settings, but it suits your machine, I assume

Thank you for checking all of this. I have checked the Max acceleration and it is 10,000.000

To be honest, I was running it at 500 speed at first, but I have now gone down to 400 in which it still slipped as per this image. Would you suggest even slower? Thank you for your recommendations, it really is appreciated.

The shift is really too quick for steps, as a guess. My machine came with the X acceleration set to 8000mm/s2, but I don’t think that’s the issue.

The size of this offset would have made an audio sound of the fields moving faster than the motor can handle… I’d think you’d hear it.

It appears to happen when there is a head directional change… I.E. when it changes direction at the end of each scan line. None of the photos are clear enough to be 100% sure.

Since you say it doesn’t occur all the time, you can’t be sure unless you switched to their software for some time to ensure it didn’t happen again.

You can try moving the head to center of table and putting pressure on the X axes in each direction to see if you can make it slip… may take a lot of pressure.

Probably have to do this with the machine on and the head positioned, it should have holding current… No need for the lps to be power up and I’d suggest not too.

It sounds like grub screws… as @bernd.dk stated…

![]()

Which seems perfectly reasonable.

For engraving fills, rather than vector lines, the controller decelerates the head to nearly a stop on each end of every line. Because there are no direction changes until the speed is very low, the scanning speed doesn’t matter.

What I wanted to verify is that the acceleration wasn’t set to something absurdly high, like 100,000 mm/s², which would cause the motor to (try to) jam to a stop. That’s not what’s happening.

Which means something is loose in between the motor and the laser head, no matter how sure you are that can’t be. ![]()

I have a 60 W OMTech that may be a cousin of yours.

The X axis belt pulley is pressed onto the motor shaft, with no setscrew to work loose. However, that doesn’t mean the pulley can’t work loose if the factory did a poor job of pressing it into place, which can happen.

To help isolate this, mark the top of the motor shaft and the pulley so you can tell if they rotate relative to each other. A blue Sharpie works well:

Run tests on cardboard, with the power dialed down so you don’t incinerate it, and watch for slippage. When it happens, immediately turn off the power and see if the pulley has moved on the shaft.

A loose pulley can rotate in either direction, which means it can reset itself after slipping when the motor reverses. By killing the power, you prevent the motor from reversing direction and (maybe) resetting the pulley’s motion.

Source: been there, watched it do that.

(Not on this laser, but elsewhere and elsewhen.)

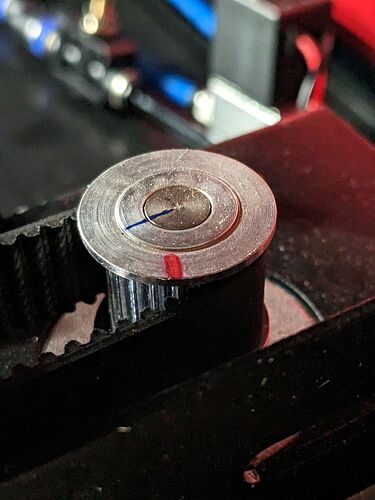

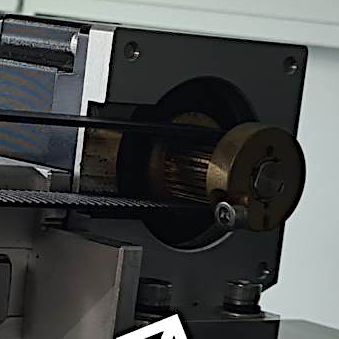

Sorry for the late reply…Once again, thank you for going through these steps to rule out any tech issues. Could I ask if this is the part you mean? Picture attached

If it doesn’t happen on the original software after many tries, what you say that Lightburn may not be compatible for the machine? It is so confusing and I really like using Lightburn, as it has lots of great editing tools

That picture shows your laser is a distant cousin of mine!

Take a close look at the pulley:

Unlike the pulley pressed onto the shaft of the X axis motor in my machine, yours has a pulley clamped around the motor shaft with a screw holding it in place. If that screw becomes even slightly loose, the pulley can rotate on the shaft and cause exactly the problem you describe.

It’s hard to tell from here, but the motor shaft seems to have at least one flat. Normally, you’d see a single screw going straight through the pulley to bear on that flat, but that’s not the case.

I’d bet serious money that the motor shaft is 6 mm in diameter and the pulley has a 1/4 inch = 6.35 mm bore, because I (think I) see a thin shim wrapped around the motor shaft to take up the difference. This isn’t the right pulley for the motor, but if the seller happened to have a lot of metric motors and inch pulleys on the shelf, well, hey, a shim can solve that problem.

If that’s the case, then we have the smoking gun: the pulley can slip around the motor shaft, because the clamp screw isn’t applying enough force to compress the shim. The shim jams against the flat in one direction, until the motor reverses with enough force to dislodge it and jam it in the other direction.

Reach in there with a hex key, seriously tighten that screw, and report how much you turned it. This may take more effort than you expect, because the screw must squash the shim against the shaft before it can increase the actual clamping force.

I expect it’ll be loose by maybe 1/6 turn. When it’s tight again, the backlash will vanish.

But, then, it does not pay a prophet to be too specific … ![]()