It is almost Christmas, our woodworking club is trying to finish off a lot of projects and of course our Voccell laser is acting up. Unfortunately, Voccell went out of business during the pandemic so I can’t go to them for help and we are not sure if our problem is caused by hardware or software issues. When printing in fill mode, the x-axis zero keeps shifting to the right resulting in letters looking italicized and circles becoming distorted ovals It is not consistent. Some letters will have the shift, others will not. Seems to work OK in line and offset fill modes. At the end of a simple print, the x-axis zero is sometimes shifted a couple inches to the right (never left). Everything looks fine in preview. Any suggestions as to what might cause this will be greatly appreciated.

Can you post some examples?

Perhaps there is a loose screw in the belt pulley on the X axis motor, so that it’s gradually slipping as the laser head travels back & forth. The screw may be buried under the belt in the toothed section of the pulley, so turn the pulley by hand (with the power off) to check the entire circumference.

If it’s a press-fit pulley, mark the end of the motor shaft and the pulley so you can detect if there’s a shift.

While you’re in there with the power off, push the laser head along the entire length of the X axis to make sure it moves smoooooothly without grittiness / obstructions / wobbles.

The belt should be snug (not guitar-string taut), all the teeth should be present, and the pulleys should not have crud built up in their teeth.

If you’re absolutely certain the machinery is fine, try this:

That problem seems to depend on imponderables allowing the machine to work perfectly for quite a while, then fail conspicuously. That looks like handwaving to me, too, but the number of times flipping that setting has solved similar problems is disturbingly high.

Back up your settings before changing anything to eliminate subsequent heartbreak of getting back to where you were.

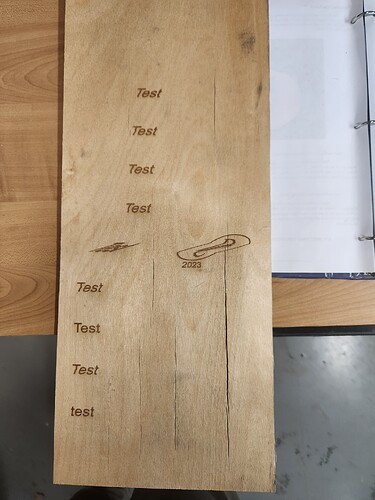

Here is an example. The text should all have been vertically aligned. Printing was from the bottom up. The logo really causes problems. It is a couple of letters with an oval around them.The speed was 200mm/sec. Using a lower speed had no effect. If you look closely at the Ts, some are squiggly and some are not.

Thanks for your very helpful response. A loose screw in the gear is a distinct possibility although I would have expected it to shift left once and a while too, if that were the case. We will definitely check that. It is a new belt and everything is clean. We will also check the Ruida settings. Thanks again.

Assuming the laser is the one I saw in the Youtube video, the top side of the X axis belt looks entirely unsupported across the entire width of the machine, which suggests it could develop a nasty oscillation at specific transit speeds, perhaps enough to slip a tooth or two.

That should cause offsets at multiples of the belt pitch, but the errors don’t look discrete enough. However, I’ve learned to stop thinking and look before ruling out possible causes.

With the power off, shove the laser head all the way to the right and mark both the belt and the motor pulley. When an engraving fails, check the belt / pulley and the pulley / motor marks to verify they’re still lined up.

Does the belt remain reasonably stable during engraving operation at 200 mm/s?

I’d expect harmonically related speeds like 100 or 400 mm/s to induce similar oscillations, so try engraving at 150 and 250 mm/s to see if the belt behaves pretty much the same way.

You may as well start marking cardboard, because this could take a lot of testing. ![]()

Thanks for the helpful suggestions, and you are right, I need to switch to cardboard.

To me, most of those “test” words seem to show shifting in both directions…to one degree or another.

By marking the end of the motor shaft I was able to confirm that the pulley is not slipping on the shaft. I cleaned and lubricated everything but that had not impact. The gantry moves very freely when the power is off, but there is significant resistance when I slide the carriage back and forth. The bearings on the carriage are free as is the idler pulley. If I remove the belt from the drive pulley, the carriage moves freely. The resistance I feel is in the stepper motor. Is this normal? Based on how easily the gantry moves, I would expect the X motor to spin freely. I’m thinking that the motor might be bad, but replacing it might be difficult. The number on it is 42BYGH108-31. I am not very familiar with steppers and am open to any advice. Thanks.

Not likely a bad motor. Stepper motors are not the same as regular motors. They

will move in steps. Have you checked the laser head for any movement?

Gantry may be suffering from racking.

Measure square from diagonal to diagonal, then opposite diagonals. Numbers should be exactly the same.

Also, grab gantry and pull.it all the eay towards you. There should be no gap behind laser head, or if there is due to design it should be exavt same measurement along the front. This is a quick racking test.

If that’s with the power off, then something is wrong …

Stepper motors have one moving part (the rotor) with a bearing on each end, so they rarely fail. However, it does happen.

With the power off, unplug the motor cable’s four-wire connector from the stepper driver. If you can’t trace the cable all the way, unplug both the X and Y axis connectors. The drivers will (should!) look pretty much like this:

It’s possible Voccell used a single six-pin connector also holding the power wires, but most likely the bottom four-pin block will pull out by itself.

With the connector unplugged, remove the X axis belt from the motor and slowly turn the pulley by hand. You will feel a slight cogging as the magnetized rotor passes the stator poles, but the pulley should turn smoothly without an absurd amount of force. If it’s rough or you can just barely turn it, there’s your problem.

Although it’s a pain, you could remove the belt(s) from the Y axis motor and do the same thing for comparison.

If the motor feels like it turns properly, plug the cable into the stepper driver and with the power still off turn the pulley again. It should feel about the same, without an increase in force. If something changed, then there’s a problem with the driver or the cable in between.

Knowing all that should get us closer to a diagnosis …

Thanks again Ed. With your help I was able to find the leads for the motor and checked the resistance. Each phase measured 2.4 ohms so I assume that indicates that the motor is electrically OK. But, it does not turn nearly as easy as the y-axis motor and I suspect that it has bad bearings. I won’t be able to get over to the workshop for a couple days, but I plan to shoot a little machine oil into the bearings and see if that makes a difference. I realize that is not a fix, but it might help to confirm the problem. Next I will be faced with finding another motor. It is a type 42BYGH108-31. When I do a search on that number, the only hit I get is in Chinese.

Thanks again for all of your excellent help.

Seems like a good diagnosis: they’re either identical motors or very close relatives.

The bearing are, of course, cartridge units that could, in theory, be replaced, but from what I know of stepper motor manufacturing, the rotors are magnetized in place after assembly. If you take the motor apart, the rotor will be partially demagnetized as it slams against the stator poles and the resulting weaker magnetization will produce only a fraction of its rated torque.

So the replaceable unit is the whole motor.

Oiling the bearing can’t hurt, but probably won’t help because they’re sealed units specifically designed to keep their internal lubricant in and any external crud out. Perhaps penetrating oil left standing overnight atop the bearing with the shaft pointed up will ooze a little where it needs to go.

Opinion: If you buy an identically sized (NEMA 23?) motor from a reputable source, as opposed to a random Amazon seller with a vowel shortage and an extensive beachware line, it’ll work just fine.

For example:

https://lightobject.com/stepping-motor/2-phase-stepper-motor/

Take care to match the shaft length / diameter / flats, because you want a pretty much drop-in replacement.

Ed,

You were so helpful when I was trying to troubleshoot my Voccell Laser Engraver that I thought you would appreciate knowing how it ended up. You will recall that I was getting “slippage” in the x direction when printing in fill mode. It did not always occur, but when it did, it resulted in characters that were slanted to the right, and the x-zero would be significantly shifted by the end of the run. The belt had been recently replaced and increasing the belt tension had no impact, suggesting that the belt was not slipping. I also checked to confirm that the drive pulley was not slipping on the shaft. This led me to believe that the “slippage” must be in the stepper motor.

Following your suggestions, I found that the X stepper motor appeared to be electrically sound with 2.4 ohms of resistance on each phase, but there seemed to be much more resistance to turning than for the y-axis motor which is about the same physical size with only a slightly different model number (and shafts on both ends). I surmised that there must be a bad bearing in the x-axis motor that was causing the motor to “skip beats.” But, on removing the motor we found that the resistance was uniform throughout a full revolution and the resistance to turning felt more magnetic than mechanical. It didn’t feel like a bad bearing. After a lot of web searches and emails to China and even Spain, I did have offers to sell me a motor which they promised was exactly what I needed. but they would never provide detailed specs on their motor, and they wanted to be paid in bitcoin. I did finally find what appeared to be a replacement for my motor but where I ended up finding it was on Amazon. I decided that a cheap motor from Amazon might actually be my safest option. It was only $12 compared to the $100 that the “bitcoin” sellers wanted so even if it didn’t last very long, it wasn’t a huge gamble.

However, when working on the motor I noticed that the x-axis belt, which had recently been replaced by a colleague, was a little different than the y-axis belts (the old x-axis belt was no longer available). The tooth spacing was the same (2mm) but the new belt is 10mm wide whereas the belts on the y-axis only measured about 9.5mm. More significantly, on closer inspection, the tooth shape was different. The teeth on the new belt were rounded but those on the y-axis belts were square, as were those on the x-axis drive pulley. I think my colleague had probably concluded that the difference was due to excessive wear on the old belt which was in pretty bad shape. I found a comparable 3/8” wide timing belt with square teeth at McMaster-Carr and ordered it.

And the result was that when I replaced the belt, my x-axis slippage went away. I never did put in the new motor I had bought because everything works fine. It was apparently belt slippage all the time. Why it was so consistent when it was slipping, I don’t understand, but I am happy to report that my problem is solved. Your advice was extremely helpful as without it, I probably would have given up. Our club had already decided that we were probably going to have to buy a new laser, but now it looks like maybe we can squeeze a little more out of this one.

Thanks again for your invaluable help and also that of others who offered suggestions.

Happy New Year

Excellent!

I keep making the invalid assumption that the belts are in fine shape and the problem must lie somewhere in the mechanics. In this case, even if I’d thought to ask, you’d have certainly said the X axis belt was in fine shape, because it had been recently (?) replaced. So much for assumptions!

@jkwilborn uploaded a book from Gates (rename the txt extension to pdf), makers of fine timing belts, showing various tooth profiles on page T-15, none of which are exactly square. I think this falls into the category of too much information, but maybe the next time you need a belt it’ll come in handy.

I’ll add “check the belts for proper fit on the pulleys” to the checklist, but I think that requires specialized knowledge that none of us have. For sure, if they’d replaced all the belts in the machine at the same time (which I’d be tempted to do on general principles), you’d have no basis for comparison and the belts would look Just Fine™.

Thanks for closing the loop around this one, because knowing what the problem really was provides more information for the next baffling problem inside a laser.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.