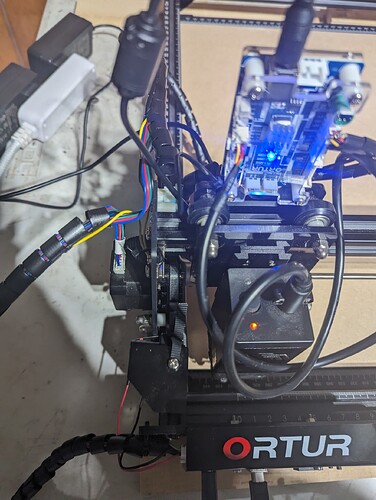

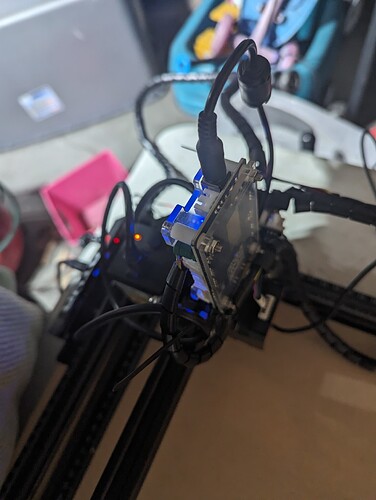

I have been having issues with my laser, Ortur Laser Master 2 S2, for so long. Originally, it was intermittent and then progressed to all of the time. I have tried communicating with Ortur support with little success. I had stopped trying well before Christmas and then finally started researching again and was looking at the wiring for the Y axis. Nothing seemed the be loose, but I un-connect and reconnected any way, and BAM it worked… for a little while. Now I’m back to it doing the same thing pretty much consistently when trying to do anything even after ensuring all wiring is good. I’ve read about the grounding issue that these had when they were new, but I just got this machine in 2023, so it should have come with it now. I don’t know what else to try? Is my wiring bad? Also, when doing research, I have yet to see a laser that looks like mine with the ‘thing’ on top (I don’t know what to call it?) I have attached a video and some pictures.

The video you uploaded shows that the laser is crashing into the frame and then triggering the y-axis hard limit. I don’t see anything unusual here, except that you command it to move where it shouldnt.

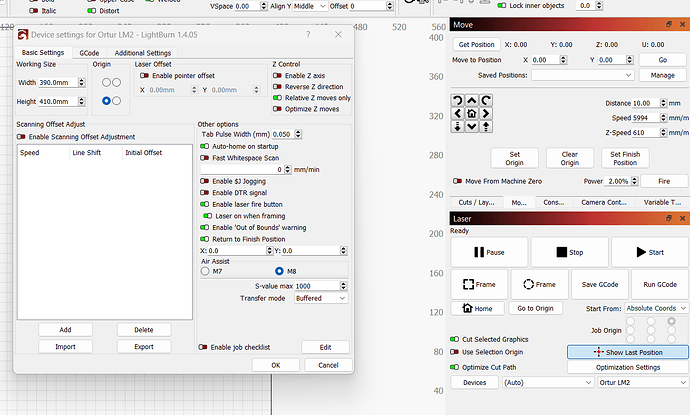

First, make sure you home correctly. Front-left, I think. Then, check which position the laser reports (move window). Next, make sure the correct workspace size is stored in the firmware, then enable hard limits and soft limits. This should prevent your laser crashing into the frame.

Edit: watched it once again. The y-axis is behaving erroneous, I guess the pulleys are not fixed to the rod. Check all mechanical parts, like described here: Guide to mechanical adjustments and maintenance

But you are still crashing into the frame at the right side.

It homes to 0.

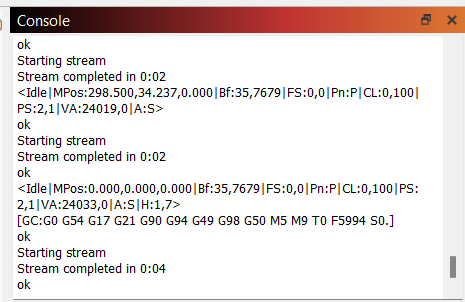

It does the same thing even when not hitting the y axis, see new video. It does seem like it is trying to go outside of the work area, but everything seems to be set up correctly. Working space, homing, origin. My design is on the grid, etc.

I will try your other suggestion too.

This is likely not the root cause but based on your Device Settings screenshot it looks like your laser is configured with the wrong device type.

Push Devices button in Laser window, select the name of your laser, then Edit. Then change the device type to “GRBL”, making sure it’s not any variation of that. Then complete the dialogue.

Can you retest after that?

I did that and retested with no change.

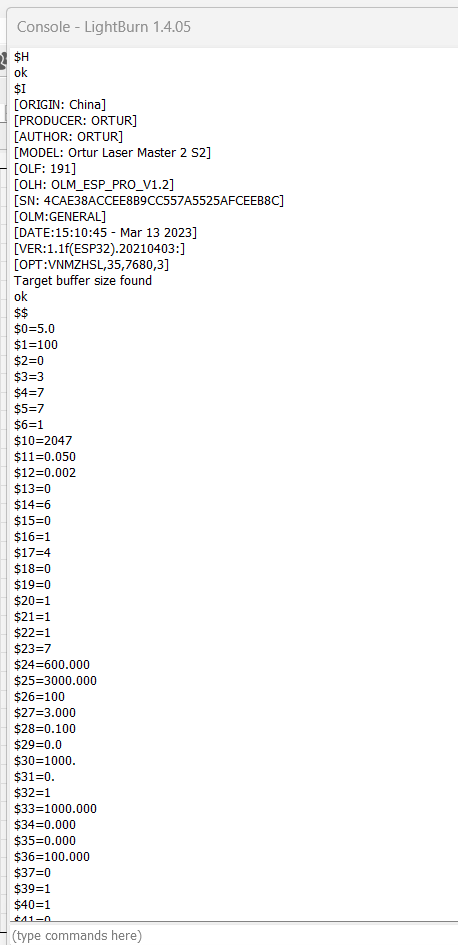

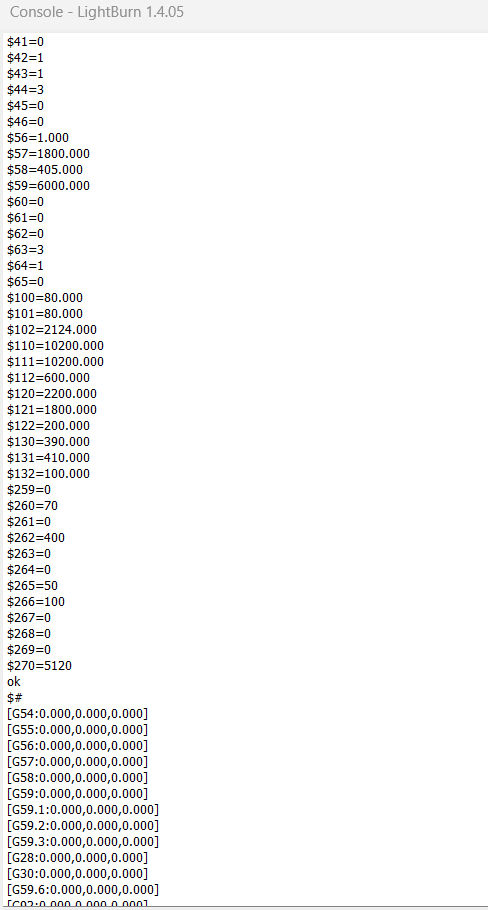

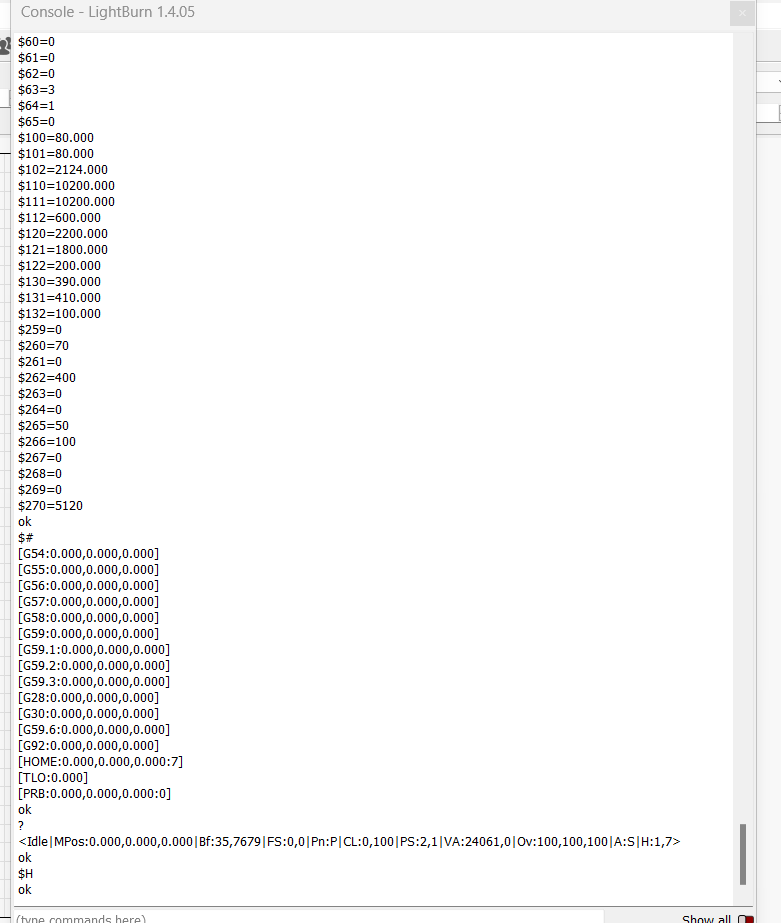

Can you run these commands in Console and return the output?

$H

$I

$$

$#

?

notice the VA 24.03 reads

This is self diagnostic of the motherboard and read the input voltage on the motherboard power adapter. It should read nearer 25v than 24v.

Are you certain BOTH power adapters are getting main power?

If so, swap them. The one from OUC plug to the motherboard

And the one from motherboard plug on OUC

If its a power issue though, by unpluging the laser head compleatly, you should be able to run ALL motions without ALARM 3, so you might want to start diagnostics by running the laser without laser head plugged in

I tried all of this with no change.

I don’t see anything unusual there.

I’d suggest doing a full mechanical review. Check belt tension. Make sure there’s no slack in the belt. They should be taught without being stretched.

Also carefully check the full length of the cables. Make sure there’s no damage anywhere along the length. Pay particularly attention to the ends.

In the original video that you posted, is the machine actually crashing to the right of the frame or does the chattering start prior to actually touching the edge. It’s hard to tell in the video.

I think your acceleration values are very high ($120 and $121). Usually, they are not higher than 1000 for common diode laser mechanics. Try reducing them.

If you move the leaser head manually (slow), do you feel any additional resistance at that position? In the video, it looks like it stopped nearly at the same position twice. I first suspected a broken stepper cable, but if it happens at the same position every time, this is unlikely. You can test by letting the head drive slowly from one corner to the opposite side and wiggling the cables at the motors to check if it behaves erratic.

I will try reducing the speed. While it does seem to happen in the same or similar spots it happens in different as well. I did put in a few values and sent it to different areas of the space manually with no issues.

Well, when I went to do this it seemed that my USB connection seemed looser than normal. The USB-b end into the laser and I could not connect to my computer. Turns out the inside white piece was broken and now completely off. The prongs are still there. I have no idea if I somehow did this in all my shuffling and testing yesterday or it is the root of all the issues… But now I am at square one and don’t know how (or if) it can be fixed.

The USB connector can be replaced, but you will need someone with experience in (SMD) soldering, I think. Maybe it’s easier to replace the board as a whole…

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.