Hey everyone! New to the Lightburn world but I’ve been working with lasers for a few years now.

I just got a new OmTech 130w Dual head for my shop. Its been a busy couple weeks getting everything squared away and I’m on my last bug that I can’t figure out.

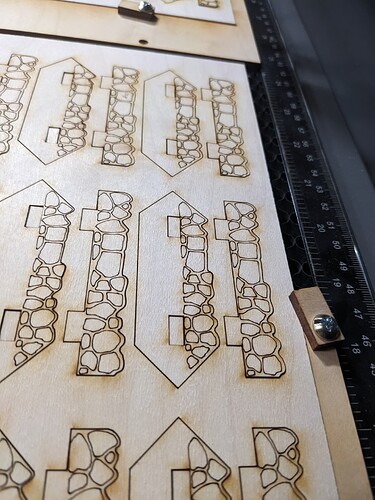

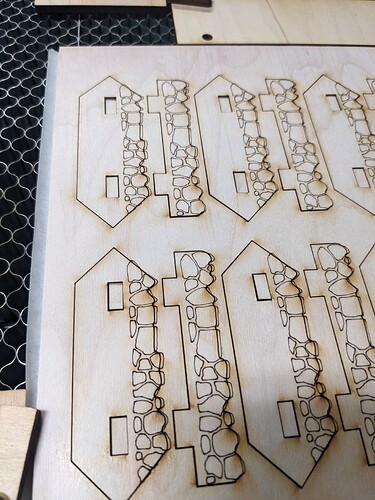

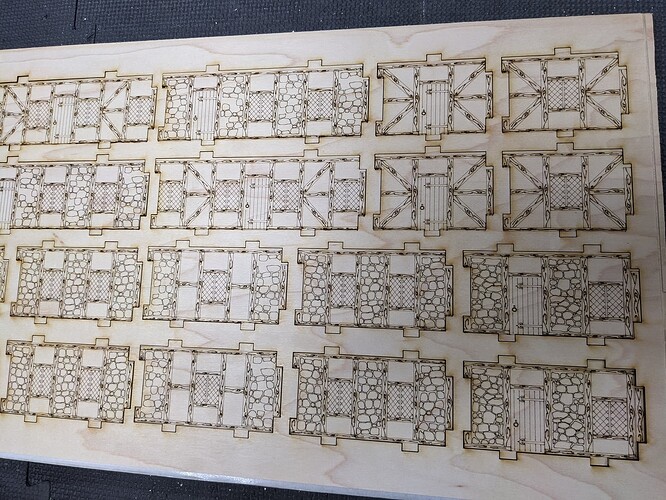

I have two line cutting files, one for cut through (27mm/s at 30% pwr), and one for engraving (400mm/s at 13.5% pwr). The top of the sheet cuts with the engraved image inside it perfectly aligned, but the further down the sheet the engraving becomes out of alignment only on the Y- axis.

I thought it could be the machine but the cut through is right on the money, mirrors are aligned, no slop in belts or any other issues with other files. Am I just trying to engrave too fast or any ideas?

I’m running a Ruida controller.

Those are the words I was looking for. ![]()

Please test this setting and let us know.

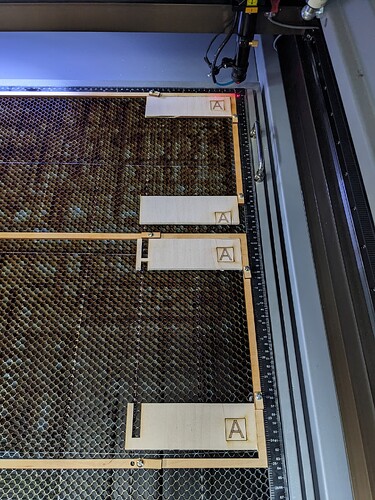

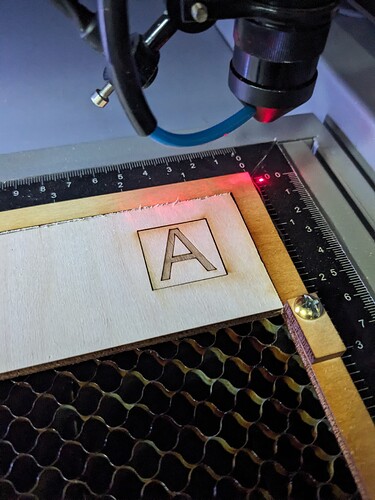

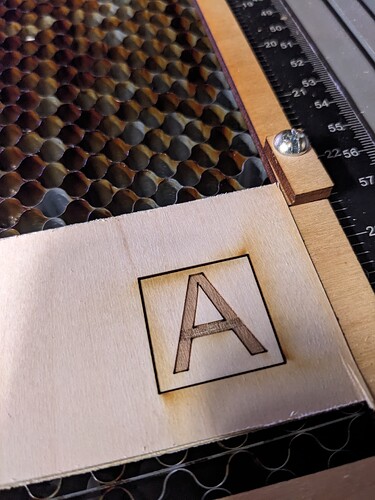

I did the test shown, the letter A with the engraving and an outline cut line around it and it went perfectly. I ran it in 4 different areas in the cutting bay from top to bottom in one program.

However when running full panels of line engraving the registration is still off.

I read in another topic here that maybe the engraving data is too dense and can cause issues? My last machine I ran on RDWorks ran these all day long so I don’t think that’s the issue but is that a possibility?

It almost seems random. Here is another panel where the first engravings on the top 3 rows are off by 1 - 1.5mm down. The bottom row, the last to engrave was only off by maybe a .25 - .5 mm. I’m quite lost on what is happening.

After a week and a half of testing speeds and power, triple checking mirrors and alignment, checking square on the machines feet, running one vs running a 12x24" panel, I fixed the issue through the Optimization Settings.

I had the whole panel grouped together so I could copy and paste and move them around as a whole. I instead grouped each set of engravings as one group. So I had 18 small groups of engraving and a cut. Then under Optimization Settings, I set it to Order by Group first, then Order by Priority. Now it engraves one piece, cuts it out, and moves on to the next and everything is peachy and in alignment.

I had it set to Order by Priority by default and it was doing all the engraving, then all the cutting. I’m guessing it was just too much engraving to handle in one go. On another forum someone had mentioned dense engraving data could be an issue, that seems to be my case.

I hope this helps someone else!

Random offsets that appear only when traversing are caused by High Accelerations and High Jump-off speeds.

Possibly a loose belt or worn mechanical components.

For a given acceleration, motion along the Y-axis requires more force, because the mass is greater than the mass would be while accelerating along the X-Axis.

Instead of adding more force, (more motors and more current) we set accelerations lower along the Y-Axis to prevent lost motion. If you engrave one image then immediately cut the perimeter around it you’re eliminating most of the potentially problematic traverse maneuver.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.