Hi,

First time here.

Looking everywhere for help and readed a lot of stuff on the web. I’ve got a Chinese Red/Black 9060 100W with Ruida RDC6442S0B. I have working with it for a month without any problems. X/Y axis were calibrated on RDworks. Until yesterday, where i found out that i have problems with Y axis.

When i make a square 10/10 cm it almost perfect (x=9,96cm and y=10,04cm), but when i want to make a square 3cm by 3 cm my result is: x=3,01 and 2,81cm! What can cause this problem? HELP!

Got new Info about it.

When i make a square 3x3cm and push Frame button on Ruida controller. Laser will position it self at the beggining of the shape. When i press start it will cut perfect. But if i want to make another shape near the first one (so the laser head need to travel) it makes X size bigger about 0.2mm then Y size.

Most likely a mechanical problem. X axis backlash

Any idea how can i get it fix?

You should check all the knots where the belt can give looseness. Engine pulley and belt. Russ explains a lot in this video. I am not a native English speaker, I use a translator. I think Russ will help more) link under the spoiler

Have you used your rotary recently, and forgotten to turn it back off? Almost every time I see issues with Y axis scale, that’s the problem - it’s a very common mistake.

Everything is right. I didn’t found any lose.

I don’t have rotary so I didn’t use this option.

Then most likely what has happened is you calibrated the machine at a specific size, but didn’t take into account that the laser beam has width.

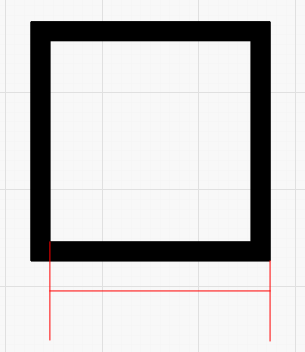

You must measure your output like this:

If you do not, you will be including the width of the beam in the calculations, and that will cause errors at other sizes.

So you suggest that calibration would be wrong ?

If only that, it will be good news

This also makes first square correct then second one wrong ?

When you calibrate, the beam has width. If you use a table saw and cut exactly along a line, it removes some material on either side of that line, and the amount depends on how wide the blade is.

A laser is no different. If you draw a square that is exactly 20mm, and cut that, if your machine is perfectly calibrated the square will be smaller than expected, and the amount smaller will be the width of the beam. The simplest way to correct for this is to measure the outside of the cut, then measure the inside, and take the average of those two - that will be the line that the laser traveled along.

Hi,

I think i got it!

It was definetly a calibration issue … it took me a lot of time to get it, but i have succed.

Right now i have a new problem… when i cut a streight line, it cut like it has DOT MODE on. a lot of small dots side by side in streight line. What it can be? i double checked and DOTS MODE is OFF

What does the preview look like? (as in, does the preview also show dots, or is it only when it gets to the laser?)

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.